This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

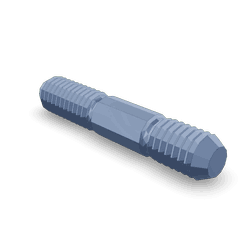

The 5340196 Double Ended Plain Stud is a component manufactured by Cummins, a well-established name in the commercial truck industry. This stud plays a significant role in the mechanical systems of commercial trucks, contributing to their efficient operation and reliability.

Basic Concepts of Double Ended Plain Studs

A Double Ended Plain Stud is a type of fastener characterized by threads on both ends and no head. It is designed to be inserted through holes in assembled parts, and nuts are then screwed onto each end to hold the parts together. The construction of these studs typically involves high-strength materials to withstand significant tensile and shear forces. In mechanical systems, they provide a secure and durable connection between components, facilitating the transfer of loads and ensuring structural integrity 1.

Purpose of the 5340196 Double Ended Plain Stud in Truck Operations

The 5340196 Double Ended Plain Stud serves multiple functions in the operation of commercial trucks. It is commonly used in engine components, transmission systems, and chassis assemblies. By providing a robust connection point, it helps in maintaining the alignment and integrity of critical truck components. Its applications range from securing engine blocks to supporting transmission housings, thereby playing a role in the overall performance and durability of the truck 2.

Key Features

The 5340196 Double Ended Plain Stud is distinguished by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring resistance to corrosion and wear. The threading on both ends is precision-cut to provide a secure fit, and the design specifications are tailored to meet the demanding requirements of commercial truck operations. These features contribute to the stud’s ability to withstand high loads and operate reliably in various environmental conditions 3.

Benefits

Using the 5340196 Double Ended Plain Stud offers several benefits. Its high-strength material composition and precise threading contribute to improved reliability in truck operations. The stud’s design allows for ease of installation, reducing downtime during maintenance procedures. Additionally, its durability minimizes the need for frequent replacements, offering maintenance advantages and contributing to the overall efficiency of truck fleets.

Installation Process

Proper installation of the 5340196 Double Ended Plain Stud involves several steps to ensure correct fitting and function. Begin by aligning the stud with the designated holes in the components to be joined. Use appropriate tools to insert the stud, ensuring it is seated correctly. Then, screw nuts onto each end of the stud, tightening them to the manufacturer’s specified torque settings. This process secures the components together, providing a strong and durable connection. It is important to follow the manufacturer’s guidelines to avoid over-tightening, which could damage the stud or the components.

Troubleshooting Common Issues

Common problems associated with Double Ended Plain Studs include loosening over time, corrosion, and damage from improper installation. To address these issues, regular inspections should be conducted to check for signs of wear or corrosion. If a stud is found to be loose, it should be re-tightened to the correct torque specification. In cases of significant corrosion or damage, the stud may need to be replaced to ensure the integrity of the connection. Proper maintenance and adherence to installation guidelines can help prevent these issues.

Maintenance Tips

To prolong the lifespan and ensure optimal performance of the 5340196 Double Ended Plain Stud, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the stud and surrounding areas can prevent the buildup of debris that may contribute to corrosion. Additionally, ensuring that nuts are tightened to the correct torque specifications during installation and maintenance checks can help maintain the integrity of the connection. Replacement guidelines should be followed when a stud shows significant signs of wear or damage.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a history spanning several decades, Cummins has established a reputation for innovation, reliability, and performance. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck operations. Cummins’ commitment to quality and customer satisfaction has made it a trusted name among truck operators and maintenance professionals.

Double Ended Plain Stud (Part 5340196) Compatibility with Cummins Engines

The Double Ended Plain Stud, part number 5340196, manufactured by Cummins, is a critical component that ensures secure fastening in various engine configurations. This part is designed to fit seamlessly with several Cummins engines, providing robust support and stability.

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F108

The Double Ended Plain Stud is compatible with the QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F108 engines. These engines share similar design elements and structural requirements, making the part a versatile solution for fastening needs across these models. The stud’s design ensures it can withstand the operational stresses and provide reliable performance in these engines.

QSF2.8 CM2880 F114

The QSF2.8 CM2880 F114 engine also benefits from the use of the Double Ended Plain Stud. This engine, while part of the same family, may have specific design nuances that the stud accommodates effectively. The part’s compatibility with the F114 model underscores its adaptability and importance in maintaining engine integrity.

In summary, the Double Ended Plain Stud (part 5340196) is a crucial component for the QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F108, and QSF2.8 CM2880 F114 engines, ensuring secure and reliable fastening across these models.

Role of Part 5340196 Double Ended Plain Stud in Engine Systems

The 5340196 Double Ended Plain Stud is integral to the assembly and operation of various engine components, ensuring secure connections and efficient performance.

Drive System Integration

In the drive system, the Double Ended Plain Stud serves as a pivotal connection point. It secures the drive components to the engine block or other structural elements, facilitating the transfer of rotational force. This stud ensures that the drive components remain firmly in place, allowing for smooth and consistent power transmission. Its role is particularly significant in high-stress environments where vibrations and dynamic loads are common, ensuring that the drive system operates reliably under varying conditions.

Fan Assembly Application

Within the fan assembly, the Double Ended Plain Stud plays a key role in attaching the fan blades to the engine’s cooling system. This connection is essential for maintaining proper airflow over the engine components, which is vital for effective cooling. The stud’s design allows for secure fastening, ensuring that the fan operates efficiently even under high RPMs. This reliable attachment helps in dissipating heat effectively, contributing to the overall thermal management of the engine.

By providing a sturdy and dependable connection in both the drive and fan systems, the Double Ended Plain Stud enhances the durability and performance of these critical engine components.

Conclusion

The 5340196 Double Ended Plain Stud is a vital component in the operation of commercial trucks, particularly in Cummins engines. Its robust design, high-strength materials, and precise threading ensure reliable performance and durability. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential to maximize the benefits of this Cummins part. Its compatibility with various Cummins engine models underscores its importance in ensuring secure and efficient engine operations.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

A. J. Wharton, Diesel Engines (Butterworth-Heinemann Ltd, 1991).

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation (SAE International, 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.