The Double End Plain Stud (C0115020400) manufactured by Cummins is a specialized fastener designed for use in commercial trucks. Its purpose is to provide a secure connection between various components within the truck’s engine and chassis systems. This stud is integral to maintaining the structural integrity and operational efficiency of commercial vehicles.

Basic Concepts

A Double End Plain Stud is a type of fastener characterized by having threaded sections on both ends, allowing it to be screwed into components from both sides. It typically consists of a cylindrical body made from high-strength materials, ensuring durability under demanding conditions. In truck mechanics, these studs play a role in securing engine components, chassis parts, and other critical assemblies, providing a robust connection that can withstand significant stress and vibration 1.

Purpose and Role in Truck Operation

The Double End Plain Stud serves a vital function in the operation of a truck by connecting and securing various components. It is used in applications where a traditional bolt and nut combination may not provide sufficient strength or where space constraints make a stud more suitable. By threading into components from both ends, it ensures a tight and secure fit, which is crucial for the safe and efficient operation of the vehicle 2.

Key Features

The C0115020400 Double End Plain Stud is designed with several key features that enhance its performance and durability. It is typically made from high-strength steel, which provides excellent resistance to wear and corrosion. The stud features a uniform thread type on both ends, ensuring a consistent and secure connection. Its design specifications are tailored to meet the rigorous demands of commercial truck applications, offering reliability and longevity 3.

Benefits

Using the Double End Plain Stud offers several benefits. Its high-strength material composition and precise thread type contribute to improved reliability, ensuring that connections remain secure under various operating conditions. The stud’s design also facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durability minimizes the need for frequent replacements, offering maintenance advantages for fleet operators 4.

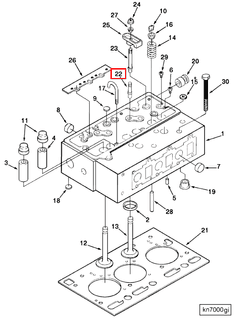

Installation Process

Proper installation of the Double End Plain Stud involves several steps to ensure a secure and lasting connection. Begin by cleaning the mating surfaces to remove any debris or contaminants. Insert the stud through the designated holes in the components, ensuring it is aligned correctly. Use appropriate tools to tighten the stud to the manufacturer’s specified torque settings, avoiding over-tightening which can damage threads or components. Verify the connection by checking for proper alignment and secure fit.

Troubleshooting and Maintenance

Common issues with the Double End Plain Stud may include loosening over time due to vibration or corrosion. Regular inspections should be conducted to check for signs of wear, such as thread damage or stud deformation. If issues are detected, the stud should be replaced to maintain the integrity of the connection. Proper maintenance, including periodic tightening and protection against corrosion, can help ensure the longevity of the stud.

Common Applications

The Double End Plain Stud is commonly used in various applications within commercial trucks. It is often found in engine assemblies, where it secures components such as cylinder heads or valve covers. Additionally, it is used in chassis applications to connect frame sections or secure brackets and mounts. Its versatility and strength make it a preferred choice for critical connections in commercial vehicle systems.

Safety Considerations

When working with the Double End Plain Stud, it is important to follow safety guidelines to ensure proper handling and installation. Use the correct tools and follow torque specifications provided by the manufacturer to avoid over-tightening or under-tightening. Be mindful of environmental conditions that may affect the stud’s performance, such as exposure to corrosive substances. Always wear appropriate personal protective equipment (PPE) when performing maintenance or installation tasks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operators.

Cummins Double End Plain Stud C0115020400 Compatibility

The Cummins Double End Plain Stud part number C0115020400 is designed to be a versatile component that fits into various engine configurations. This particular stud is engineered to provide a secure and reliable connection in engine assemblies, ensuring stability and durability under operational conditions.

Compatibility with Specific Engine Models

3A1.7 and 6A3.4 Engines

The Double End Plain Stud C0115020400 is compatible with both the 3A1.7 and 6A3.4 engines. These engines, while differing in size and power output, share common design principles that allow this stud to be used across both models. The stud’s design ensures it can withstand the mechanical stresses and thermal variations inherent in these engines, providing a critical fastening solution in various engine components.

A2300 Engine

The A2300 engine also benefits from the use of the Double End Plain Stud C0115020400. This engine, known for its robust performance, requires high-quality fasteners to maintain its operational integrity. The stud’s double-end functionality allows for versatile installation, accommodating different mounting requirements within the engine’s architecture.

Grouping of Engine Models

When considering the compatibility of the Double End Plain Stud C0115020400, it is useful to group the engines based on their design and operational characteristics. The 3A1.7 and 6A3.4 engines, despite their differences in displacement and power, share a commonality in their need for reliable fastening solutions. This commonality is reflected in the stud’s design, which is optimized for use in these engines.

The A2300 engine, while distinct in its specifications, also requires the same level of precision and durability in its fasteners. The Double End Plain Stud C0115020400 meets these requirements, ensuring that the engine operates smoothly and efficiently.

By understanding the compatibility of the Double End Plain Stud C0115020400 with these engines, technicians and engineers can confidently use this part in their maintenance and repair tasks, knowing it is designed to fit and function effectively within these engine models.

Role of Part C0115020400 Double End Plain Stud in Engine Systems

The C0115020400 Double End Plain Stud is an essential component in various engine systems, facilitating the secure attachment of multiple parts to ensure optimal performance and reliability. This stud is integral in maintaining the structural integrity and alignment of engine components, directly influencing the overall efficiency and durability of the engine.

In the context of parts performance, the Double End Plain Stud plays a significant role by providing a robust connection point for critical engine parts. Its design allows for even distribution of stress and load, which is vital for the longevity and consistent performance of the engine. By securely fastening components such as cylinder heads, valve covers, and other performance parts, it ensures that these elements remain firmly in place under the high pressures and temperatures typical of engine operation.

When considering performance parts, the stud’s reliability is paramount. High-performance engines often operate at extreme conditions, and the Double End Plain Stud must withstand these without failure. Its use in performance applications ensures that modifications and upgrades, such as aftermarket cylinder heads or valvetrain components, are securely mounted. This not only enhances the engine’s performance but also maintains safety standards by preventing part dislodgement or failure during operation.

Conclusion

The C0115020400 Double End Plain Stud is a foundational element in engine systems, contributing to the secure attachment and optimal performance of various components. Its role in both standard and high-performance engines underscores its importance in maintaining engine integrity and efficiency.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.