This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

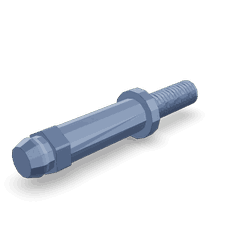

The Clinch Stud 3681498 is a component manufactured by Cummins, a well-established name in the heavy-duty truck industry. This Cummins part is designed to play a specific role in the engine systems of heavy-duty trucks, contributing to the overall performance and durability of the engine. Cummins, known for its commitment to quality and innovation, produces this part to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Clinch Studs

Clinch studs are specialized fasteners used in engine construction to secure components in place. They function by threading into a pre-tapped hole and then expanding at the base to create a secure fit, which helps in maintaining the integrity of the engine. The use of clinch studs is particularly important in high-stress environments where traditional bolts might fail due to vibration or thermal expansion 2.

Purpose of the 3681498 Clinch Stud

The 3681498 Clinch Stud is specifically engineered to secure critical components within the engine of a heavy-duty truck. It plays a role in ensuring that parts remain firmly in place under the extreme conditions encountered in heavy-duty applications. By providing a reliable fastening solution, this Cummins part contributes to the engine’s performance and longevity 3.

Key Features

The 3681498 Clinch Stud is characterized by several key features that enhance its functionality. It is made from high-strength materials to withstand the rigors of heavy-duty use. The design includes a threaded section for easy installation and a base that expands upon tightening to create a secure fit. Additionally, the stud may feature unique characteristics such as corrosion resistance or heat treatment to improve its durability in harsh environments 4.

Benefits

Using the 3681498 Clinch Stud offers several advantages. It provides improved engine reliability by ensuring that components remain securely fastened. This can lead to enhanced engine performance and increased longevity. When compared to alternative fastening methods, clinch studs often provide a more permanent and vibration-resistant solution, which is particularly beneficial in the demanding conditions of heavy-duty truck engines 5.

Installation Process

Proper installation of the 3681498 Clinch Stud is crucial for its effectiveness. The process involves threading the stud into a pre-tapped hole and then using a specialized tool to expand the base, creating a secure fit. It is important to follow the manufacturer’s guidelines for torque specifications and to use the correct tools to ensure the clinch stud is installed correctly 6.

Maintenance and Troubleshooting

Regular maintenance of the 3681498 Clinch Stud is important to ensure optimal performance. This may involve periodic inspection for signs of wear or corrosion. Common issues that may arise include loosening of the stud or damage to the threads. Troubleshooting tips include ensuring proper installation techniques are used and replacing the clinch stud if it shows signs of wear or failure 7.

Compatibility and Applications

The 3681498 Clinch Stud is designed for use in specific engine types and truck models. It is commonly applied in scenarios where secure fastening is critical to engine performance and durability. The part’s design and material composition make it particularly suitable for heavy-duty applications where traditional fasteners may not suffice 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s product range includes a variety of engine and component solutions designed to meet the needs of demanding applications 9.

Clinch Stud 3681498 in Cummins Engines

The Clinch Stud 3681498, manufactured by Cummins, plays a role in the assembly and functionality of several Cummins engine models. This particular part is integral to the structural integrity and operational efficiency of the engines, ensuring secure fastening and stability.

ISX CM570 and ISX CM870 Engines

In the ISX CM570 and ISX CM870 engines, the Clinch Stud 3681498 is utilized in various applications where a robust and reliable fastening mechanism is required. These engines, known for their power and durability, benefit from the precision and strength provided by this component. The clinch stud is typically used in areas where traditional screws and bolts may not provide the necessary hold or where vibration resistance is critical.

The clinch stud’s design allows it to be securely anchored into place, providing a permanent and reliable connection. This is particularly important in high-stress environments where the engine operates under significant load and vibration. The use of the clinch stud in these engines ensures that components remain tightly fastened, reducing the risk of loosening and potential engine failure.

By integrating the Clinch Stud 3681498 into the ISX CM570 and ISX CM870 engines, Cummins maintains the high standards of quality and performance that these models are known for. The clinch stud’s role in these engines highlights the importance of precision components in achieving optimal engine performance and longevity 10.

Role of Part 3681498 Clinch Stud in Engine Systems

The part 3681498 Clinch Stud is integral to several components within engine systems, ensuring secure and reliable connections.

In the Accessory Support Arrangement, the Clinch Stud provides a robust mounting point for various accessories, such as alternators and air conditioning compressors. This secure attachment is vital for the stable operation of these components, ensuring they function efficiently without risk of detachment.

For the Air Intake Connection, the Clinch Stud plays a significant role in maintaining a tight seal between the air intake system and the engine. This seal is essential for optimal airflow into the engine, directly influencing combustion efficiency and overall performance.

In the context of the Engine Control Module (ECM), the Clinch Stud is used to secure the ECM housing to the engine or chassis. This ensures that the ECM remains in a fixed position, protected from vibrations and external impacts, which could otherwise interfere with its operation.

Lastly, in the Intake Connection Mounting, the Clinch Stud facilitates a secure connection between the intake manifold and the engine block. This connection is fundamental for maintaining the integrity of the intake system, ensuring that air enters the engine consistently and without leaks, which is paramount for engine performance and fuel efficiency 11.

Conclusion

The 3681498 Clinch Stud by Cummins is a critical component in the engine systems of heavy-duty trucks, providing secure and reliable fastening solutions. Its design and material composition make it suitable for the demanding conditions of heavy-duty applications, contributing to engine performance and longevity. Proper installation, maintenance, and understanding of its role in various engine components are essential for maximizing the benefits of this Cummins part.

-

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX12 CM2350 X102. Bulletin Number 4310645.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.