3902501

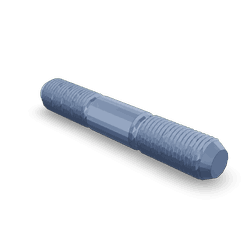

Double End Plain Stud

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3902501 Double Ended Plain Stud by Cummins is a specialized component designed for heavy-duty truck applications. This stud serves a pivotal role in ensuring the structural integrity and efficient operation of various truck systems. Its design and functionality are tailored to meet the demanding requirements of heavy-duty environments, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of Double Ended Plain Studs

A Double Ended Plain Stud is a type of fastener characterized by threaded sections on both ends and a smooth, unthreaded section in the middle. This design allows it to be used in applications where traditional bolts might not be suitable. In mechanical systems, these studs provide a secure and stable connection between components, often used in conjunction with nuts to create a robust assembly. The unthreaded middle section facilitates alignment and reduces stress concentrations, enhancing the durability of the connection 2.

Role of the 3902501 Double Ended Plain Stud in Truck Operation

The 3902501 Double Ended Plain Stud plays a specific role in the operation and maintenance of heavy-duty trucks. It is commonly employed in applications where high tensile strength and resistance to vibration are required. This stud helps in securing critical components, ensuring that they remain firmly in place under the rigors of heavy-duty use. Its application in truck engines, transmissions, and other mechanical systems contributes to the overall stability and performance of the vehicle 3.

Key Features

The 3902501 Double Ended Plain Stud boasts several key features that enhance its functionality and reliability. It is constructed from high-quality materials, typically alloy steel, which provides excellent strength and durability. The stud features a uniform thread type on both ends, ensuring a secure fit with corresponding nuts. Additionally, its design includes precise dimensions and tolerances to guarantee proper alignment and performance in demanding applications.

Benefits of Using the 3902501 Double Ended Plain Stud

Utilizing the 3902501 Double Ended Plain Stud offers several advantages. Its robust material composition and precise manufacturing ensure high durability, reducing the likelihood of failure under stress. The stud’s design facilitates ease of installation, allowing for quick and efficient assembly. Furthermore, its reliable performance enhances the overall efficiency and safety of the truck’s mechanical systems.

Installation Process

Proper installation of the 3902501 Double Ended Plain Stud involves several steps to ensure a secure and lasting connection. Begin by cleaning the installation area to remove any debris or contaminants. Next, align the stud with the designated holes in the components to be joined. Use appropriate tools, such as a torque wrench, to tighten the nuts on both ends of the stud to the specified torque settings. This ensures that the connection is neither overtightened nor undertightened, maintaining the integrity of the assembly.

Troubleshooting Common Issues

Common problems associated with Double Ended Plain Studs include loosening due to vibration, corrosion, and thread damage. To address these issues, regularly inspect the studs for signs of wear or corrosion. If loosening is detected, re-torque the nuts to the manufacturer’s specifications. In cases of corrosion, clean the affected areas and apply a suitable anti-corrosion treatment. For thread damage, replace the stud to prevent further complications.

Maintenance Tips

To ensure the longevity and optimal performance of the 3902501 Double Ended Plain Stud, regular maintenance is recommended. Inspect the stud and its connections during routine service intervals. Look for signs of wear, corrosion, or loosening. Apply lubricants as necessary to reduce friction and prevent seizing. Additionally, protect the stud from environmental factors that could accelerate wear or corrosion, such as moisture and chemicals.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as power generation equipment and component solutions. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility of Double Ended Plain Stud Part 3902501 with Cummins Engines

The Double Ended Plain Stud part number 3902501, manufactured by Cummins, is a versatile component that fits a variety of Cummins engines. This part is designed to provide robust and reliable fastening in engine applications, ensuring secure connections that can withstand the rigors of engine operation.

Cummins B Series Engines

The B series engines, including B4.5, B5.9 GAS PLUS CM556, and B6.7S, are medium-duty engines known for their durability and efficiency. The Double Ended Plain Stud part 3902501 is compatible with these engines, providing a critical fastening solution for various engine components.

Cummins ISB Series Engines

The ISB series engines, such as ISB3.9 CM2220 B107, ISB4.5 CM2350 B104, and ISB5.9 CM2880 B127, are high-performance engines used in a variety of applications, from heavy-duty trucks to industrial machinery. The Double Ended Plain Stud part 3902501 is engineered to fit these engines, ensuring secure and reliable connections in demanding environments.

Cummins QSB Series Engines

The QSB series engines, including QSB3.9 30 CM550, QSB3.9 CM2880 B138, QSB5.9 30 CM550, and QSB5.9 CM2880 B139, are known for their power and efficiency. The Double Ended Plain Stud part 3902501 is compatible with these engines, providing a dependable fastening solution for critical engine components.

Cummins ISF Series Engines

The ISF series engines, such as ISF3.8 CM2350 F107, are designed for applications requiring high torque and reliability. The Double Ended Plain Stud part 3902501 fits these engines, ensuring secure fastening in various engine configurations.

Cummins F Series Engines

The F series engines, including F3.8 CM2350 F128C, F3.8 CM2620 F137B, F4.5 CM2620 F139B, and F4.5 CM2620 F141C, are versatile engines used in a range of applications. The Double Ended Plain Stud part 3902501 is compatible with these engines, providing a reliable fastening solution for various engine components.

Cummins D Series Engines

The D series engines, such as D4.0 CM2620 D103B, are designed for durability and performance. The Double Ended Plain Stud part 3902501 fits these engines, ensuring secure connections in demanding applications.

Cummins QSF Series Engines

The QSF series engines, such as QSF3.8 CM2350 F107, are known for their efficiency and reliability. The Double Ended Plain Stud part 3902501 is compatible with these engines, providing a dependable fastening solution for various engine components.

The Double Ended Plain Stud part 3902501 is a critical component for maintaining the integrity and performance of these Cummins engines, ensuring reliable operation across a wide range of applications.

Role of Part 3902501 Double Ended Plain Stud in Engine Systems

In the intricate assembly of engine systems, the Double Ended Plain Stud, part number 3902501, serves as a pivotal component in ensuring the structural integrity and efficient operation of various engine elements. This stud is instrumental in the secure attachment and alignment of multiple components, facilitating the seamless transfer of power and maintaining the precise positioning of parts under operational stress.

Integration with Coupling and Drive Mechanisms

The Double Ended Plain Stud is often utilized in the assembly of coupling and drive mechanisms. It provides a robust connection point that ensures the coupling remains firmly attached to the drive system. This secure attachment is essential for the efficient transfer of rotational force from the engine to other components, such as the rear gear train accessory, ensuring smooth and reliable operation.

Fuel System Applications

In fuel systems, particularly with fuel pumps and their associated components, the Double Ended Plain Stud plays a significant role. It is used in the fuel pump conversion kit to ensure that the fuel pump is securely mounted and aligned within the engine bay. This stud helps in maintaining the integrity of the fuel pump coupling, which is vital for the consistent delivery of fuel to the engine. Additionally, it supports the fuel pump mounting structure, ensuring that the pump operates within the specified parameters for optimal fuel injection and engine performance.

Supporting the Short Block and Accessory Components

Within the short block of an engine, the Double Ended Plain Stud is employed to secure spacers and other accessory components. Its use in the fan pilot assembly ensures that the fan operates efficiently, contributing to the engine’s cooling system. By providing a stable mounting point, this stud helps in maintaining the alignment and operational efficiency of these components, which are essential for the engine’s overall performance and longevity.

Enhancing Structural Integrity

Across various engine systems, the Double Ended Plain Stud enhances structural integrity by providing a strong, reliable connection between components. Its application in mounting and coupling scenarios ensures that parts remain securely in place, even under the high stresses and vibrations typical of engine operation. This reliability is fundamental to the engine’s durability and performance, making the Double Ended Plain Stud an indispensable component in engine assembly and maintenance.

Conclusion

The 3902501 Double Ended Plain Stud by Cummins is a critical component in the maintenance and operation of heavy-duty trucks and various Cummins engines. Its robust design, high-quality materials, and precise manufacturing ensure durability, ease of installation, and reliable performance. Regular maintenance and proper installation are essential to maximize the benefits of this stud, contributing to the overall efficiency and safety of the vehicle’s mechanical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.