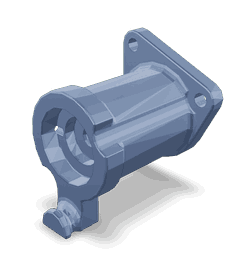

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3177126 Pivot Shaft Support is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is fundamental for fleet operators and maintenance personnel.

Function and Operation

The Pivot Shaft Support operates by providing structural integrity and support to the pivot shaft within the truck’s system. It interacts with various components, ensuring smooth and reliable operation of the pivot mechanism. This support allows for the necessary movement and stability required for the efficient functioning of the truck’s systems 1.

Key Features

The Cummins 3177126 Pivot Shaft Support is characterized by its robust material composition, typically featuring high-strength alloys that enhance durability. Its design incorporates precise engineering to ensure compatibility and optimal performance. Unique characteristics may include specific mounting points or reinforcement areas that contribute to its functionality 2.

Role in Truck Operation

In the context of truck operation, the Pivot Shaft Support plays a role by maintaining the alignment and stability of the pivot shaft. This contributes to the truck’s performance by ensuring that movements are executed smoothly and efficiently. Its proper function is integral to the truck’s overall operational effectiveness 3.

Benefits

The advantages of the Cummins 3177126 Pivot Shaft Support include enhanced durability and reliability, which can lead to reduced maintenance requirements and potential cost savings for fleet operators. Its design and material composition are aimed at providing long-term performance and resilience under demanding conditions 4.

Installation and Compatibility

Proper installation of the Pivot Shaft Support involves following manufacturer guidelines to ensure it is securely and correctly positioned within the truck’s system. Compatibility with different truck models should be verified to ensure optimal performance and integration with existing components 5.

Maintenance and Troubleshooting

Routine maintenance practices for the Pivot Shaft Support may include regular inspections for wear or damage, lubrication of moving parts, and ensuring all connections are secure. Troubleshooting common issues might involve checking for alignment problems, inspecting for signs of wear, and addressing any detected issues promptly to maintain performance 6.

Safety Considerations

When working with the Pivot Shaft Support, it is important to observe safety protocols to prevent accidents or injuries. This includes ensuring the truck is properly secured and powered down before beginning any work, using appropriate personal protective equipment, and following all manufacturer safety guidelines 7.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its comprehensive range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of diesel engines, related technologies, and customer support 8.

Compatibility with Cummins Engines

The Pivot Shaft Support, identified by the part number 3177126, is a critical component in several Cummins engine models. This part is designed to provide stability and support to the pivot shaft, ensuring smooth operation and longevity of the engine. Below is a detailed description of its compatibility with various Cummins engines:

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The Pivot Shaft Support 3177126 is integral to the QSK38 series engines, particularly those with model numbers CM2150 MCRS and CM850 MCRS. This part ensures the pivot shaft remains securely in place, facilitating efficient power transfer and reducing wear on the engine components 9.

QSK50 Series

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

In the QSK50 series, the Pivot Shaft Support 3177126 is essential for maintaining the structural integrity of the pivot shaft. It is compatible with both CM2150 MCRS and CM2350 K108 models, ensuring that the engine operates smoothly and efficiently 10.

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

The QSK60 series engines, including CM500, CM850 MCRS, and QSK60G, also benefit from the Pivot Shaft Support 3177126. This part is crucial for maintaining the alignment and stability of the pivot shaft, which is vital for the overall performance of the engine 11.

QSK45 and QSK78 Series

- QSK45 CM500

- QSK78 CM500

For the QSK45 CM500 and QSK78 CM500 engines, the Pivot Shaft Support 3177126 is designed to provide the necessary support and stability to the pivot shaft. This ensures that the engine operates with minimal friction and maximum efficiency 12.

Role in Engine Systems

The Cummins 3177126 Pivot Shaft Support is an integral component in the orchestration of several engine systems, ensuring smooth operation and efficiency. Its primary function is to provide a stable and pivotable mounting point for the pivot shaft, which is essential for the dynamic movement required in various engine components.

In the context of the Belt Tensioner system, the Pivot Shaft Support allows for precise adjustments of belt tension. This is vital for maintaining the correct amount of pressure on the belts, ensuring they drive the pulleys efficiently without slipping or excessive wear.

Within the Drive Arrangement Fan and Fan Arrangement systems, the Pivot Shaft Support facilitates the rotational movement of the fan. This movement is necessary for proper airflow through the Radiator and Radiator Cooling system, helping to dissipate heat effectively and maintain optimal engine temperature.

The Fan Drive and Fan Drive Arrangement benefit from the Pivot Shaft Support by allowing the fan to engage and disengage as needed. This is particularly important in modern engines where fan operation is controlled electronically to improve fuel efficiency and reduce noise.

In the Fan Drive Mounting system, the Pivot Shaft Support ensures that the fan drive mechanism is securely mounted yet able to pivot as required. This is essential for accommodating thermal expansion and contraction of engine components, which can otherwise lead to misalignment and failure.

The Fan Idler and Fan Idler Assembly also rely on the Pivot Shaft Support to maintain proper alignment and tension. The idler’s role is to keep the belt properly tensioned and aligned, and the Pivot Shaft Support ensures that this can be done dynamically as the engine operates under varying loads.

Lastly, in the Idler Lever and Idler Assembly Fan systems, the Pivot Shaft Support allows for the necessary pivoting action that enables the idler lever to adjust belt tension automatically. This is particularly important in systems where automatic tensioners are used to maintain optimal belt tension throughout the engine’s operating range.

Conclusion

In summary, the Cummins 3177126 Pivot Shaft Support plays a significant role in the efficient and reliable operation of various engine systems by providing a stable yet pivotable mounting point for critical components. Its compatibility across multiple Cummins engine models underscores its importance in maintaining engine performance and reliability.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (2023). Cummins Product Compatibility Guide. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). Maintenance and Troubleshooting Guide for Cummins Engines. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). Safety Guidelines for Cummins Engine Maintenance. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). QSK38 Engine Series Compatibility. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). QSK50 Engine Series Compatibility. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). QSK60 Engine Series Compatibility. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (2023). QSK45 and QSK78 Engine Series Compatibility. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.