This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

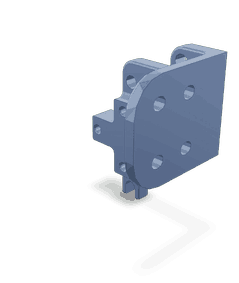

The Belt Tensioner Support 3681129, manufactured by Cummins, is a critical component in the commercial truck industry, ensuring the efficient operation of engine systems by maintaining proper belt tension.

Basic Concepts of Belt Tensioner Support

A Belt Tensioner Support is a device that maintains the correct tension on the belts driving various engine accessories. It operates through a spring-loaded mechanism or hydraulic pressure, automatically adjusting the tension as the belts wear or as engine conditions change 1. This ensures that the belts remain taut, which is necessary for the efficient transfer of power to components such as the alternator, water pump, and air conditioning compressor.

Purpose of Belt Tensioner Support 3681129

The Belt Tensioner Support 3681129 ensures that the belts driving engine accessories are kept at the optimal tension. This contributes to engine efficiency and performance by reducing slippage and wear on the belts, leading to improved reliability and longevity of the engine system 2.

Key Features

The Belt Tensioner Support 3681129 is characterized by its robust material composition, typically featuring high-strength alloys that resist wear and corrosion. Its design incorporates precision engineering to ensure accurate tension maintenance. Unique characteristics may include an integrated dampening system to reduce vibrations and noise, enhancing the overall functionality and comfort of the truck’s operation.

Benefits

The advantages provided by the Belt Tensioner Support 3681129 include improved engine performance through consistent belt tension, reduced wear on belts leading to longer service intervals, and enhanced reliability of the truck’s engine system. These benefits contribute to the overall efficiency and durability of the vehicle.

Installation Process

Proper installation of the Belt Tensioner Support 3681129 involves several steps. First, ensure the engine is cool and the belts are removed. Then, using the appropriate tools, mount the tensioner support in its designated location. It is important to follow the manufacturer’s guidelines for torque specifications and alignment to ensure correct fitting. After installation, refit the belts and check the tension to confirm proper operation.

Troubleshooting Common Issues

Common problems associated with Belt Tensioner Supports can include noise from the tensioner, belt slippage, or failure of the tensioner mechanism. Potential causes may be wear and tear, incorrect installation, or lack of maintenance. Recommended solutions or adjustments include inspecting and replacing worn components, ensuring correct installation, and regular maintenance to address these issues.

Maintenance Tips

Regular maintenance practices for the Belt Tensioner Support 3681129 are vital to ensure longevity and optimal performance. This includes periodic inspection for signs of wear or damage, checking the tension of the belts, and ensuring the tensioner operates smoothly. Adhering to recommended inspection intervals and addressing any issues promptly can prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for quality, reliability, and innovation. Their product range is designed to meet the demanding requirements of commercial applications, ensuring high performance and durability.

Belt Tensioner Support Part 3681129 in Cummins Engines

The Belt Tensioner Support part 3681129, manufactured by Cummins, is an integral component in the engine systems of several Cummins engine models. This part plays a role in maintaining the proper tension of the engine belts, ensuring efficient operation and longevity of the engine.

QSX15 Engine

In the QSX15 engine, the Belt Tensioner Support part 3681129 is designed to work seamlessly with the engine’s belt system. It ensures that the belts are held at the correct tension, which is vital for the proper functioning of the engine’s ancillary systems, such as the alternator, water pump, and air conditioning compressor. This support helps in reducing wear and tear on the belts and the pulleys, thereby extending the overall lifespan of these components.

CM2250 Engine

Similarly, in the CM2250 engine, the Belt Tensioner Support part 3681129 is engineered to fit precisely within the engine’s design. It supports the belt tensioner, ensuring that the belts maintain the necessary tension to drive the engine’s accessories effectively. This support is crucial for maintaining the efficiency of the engine’s power generation and cooling systems.

ECF Engine

The ECF engine also benefits from the Belt Tensioner Support part 3681129. This part is specifically designed to integrate with the ECF engine’s belt routing system. By providing the necessary support to the belt tensioner, it ensures that the belts are kept at the optimal tension, which is essential for the smooth operation of the engine’s various components.

Grouping of Engines

The Belt Tensioner Support part 3681129 is compatible with the QSX15, CM2250, and ECF engines, which are part of Cummins’ lineup of commercial and industrial engines. These engines are known for their reliability and performance in various applications, including heavy-duty trucks, construction equipment, and industrial power generation. The use of this support part in these engines underscores Cummins’ commitment to providing high-quality components that enhance engine performance and durability.

Role of Part 3681129 Belt Tensioner Support in Engine Systems

The 3681129 Belt Tensioner Support is an integral component in maintaining the optimal operation of various engine systems. It ensures that the drive belt is properly tensioned, which is essential for the efficient transfer of power from the engine to other components.

Interaction with the Drive System

In the drive system, the 3681129 Belt Tensioner Support plays a significant role by keeping the drive belt at the correct tension. This is important for several reasons:

-

Consistent Power Transmission: Proper tension ensures that the drive belt can transmit power efficiently from the engine to other components such as the alternator, water pump, and power steering pump. Without adequate tension, the belt may slip, leading to inefficient power transfer and potential component failure.

-

Reduced Wear and Tear: Maintaining the correct tension helps in minimizing the wear and tear on the drive belt. A loose belt can cause excessive slippage, leading to accelerated degradation and a shorter lifespan for the belt.

Integration with the Fan System

The fan system, which is responsible for cooling the engine, also benefits from the 3681129 Belt Tensioner Support. The support ensures that the belt driving the fan is correctly tensioned, which is vital for:

-

Efficient Cooling: Proper belt tension ensures that the fan operates at its intended speed, providing adequate cooling for the engine. Insufficient tension can result in the fan running slower than required, leading to overheating issues.

-

Stable Operation: The 3681129 Belt Tensioner Support helps in maintaining a stable and consistent operation of the fan belt. This stability is crucial for the reliable functioning of the cooling system, especially under varying engine loads and speeds.

By ensuring that both the drive and fan systems operate with the correct belt tension, the 3681129 Belt Tensioner Support contributes to the overall reliability and performance of the engine.

Conclusion

The Belt Tensioner Support 3681129 by Cummins is a vital component in maintaining the efficiency and reliability of engine systems in commercial trucks. Its role in ensuring proper belt tension contributes to consistent power transmission, reduced wear and tear, and stable operation of engine accessories. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.