This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

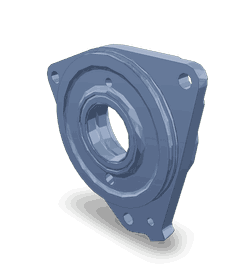

The AR12780 Hydraulic Pump Support, manufactured by Cummins, is a component designed to enhance the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of truck operations. This Cummins part is significant in maintaining the functionality of hydraulic systems within these vehicles.

Basic Concepts of Hydraulic Pump Support

Hydraulic systems in trucks are responsible for a variety of functions, including braking, steering, and the operation of various attachments like cranes or lifts. The hydraulic pump support plays a role in these systems by providing a stable mounting point for the hydraulic pump. This stability is important for the consistent operation of the pump, which in turn ensures the reliable performance of the hydraulic system 1.

Purpose of the AR12780 Hydraulic Pump Support

The AR12780 Hydraulic Pump Support is designed to secure the hydraulic pump within the truck’s hydraulic system. Its function is to provide a firm and stable base for the pump, which is necessary for the pump to operate efficiently. This support contributes to the overall functionality of the hydraulic system by ensuring that the pump can deliver consistent hydraulic pressure, which is vital for the operation of hydraulic-driven components in the truck 2.

Key Features

The AR12780 Hydraulic Pump Support features a robust design that incorporates high-quality materials to ensure durability and reliability. Its design elements include precision-machined mounting surfaces and alignment features that facilitate accurate installation. The materials used are selected for their strength and resistance to the harsh conditions often encountered in commercial truck environments. Unique characteristics of this support may include corrosion-resistant coatings and vibration-damping features that enhance its performance 3.

Benefits

The AR12780 Hydraulic Pump Support offers several benefits to the hydraulic system. It contributes to improved reliability by providing a stable platform for the pump, which reduces the likelihood of pump failure due to movement or misalignment. Efficiency is enhanced as the support allows for optimal pump operation, leading to consistent hydraulic pressure. Durability is also a key benefit, as the support is designed to withstand the rigors of commercial truck use, ensuring long-term performance 4.

Installation

When installing the AR12780 Hydraulic Pump Support, it is important to follow guidelines and best practices to ensure proper function. Preparatory steps may include cleaning the mounting area and inspecting the support for any damage. Tools required for installation will vary but may include torque wrenches for securing the support to the truck’s frame. Installation procedures should be carried out in accordance with the manufacturer’s instructions to ensure that the support is correctly aligned and securely fastened.

Maintenance

Regular maintenance of the AR12780 Hydraulic Pump Support is recommended to ensure continued reliable operation. Inspection intervals should be established based on the truck’s usage and operating conditions. Cleaning procedures may involve removing dirt and debris from the support to prevent buildup that could affect performance. Lubrication requirements, if any, should be followed to maintain moving parts and reduce wear.

Troubleshooting

Common issues with the AR12780 Hydraulic Pump Support may include misalignment, wear, or damage from use. Diagnostic steps for identifying problems should begin with a visual inspection of the support and the pump for signs of wear or damage. Suggested remedies or repairs may involve realigning the support, replacing worn components, or addressing any damage to ensure the hydraulic system operates correctly.

Performance Enhancements

Potential upgrades or modifications to the AR12780 Hydraulic Pump Support may include the addition of vibration-damping materials or the use of higher-strength fasteners. These enhancements can be made to improve the support’s performance or compatibility with other systems, depending on the specific requirements of the truck’s hydraulic system.

Safety Considerations

When working with the AR12780 Hydraulic Pump Support, it is important to observe safety guidelines and precautions. This includes ensuring that the truck is properly secured and the hydraulic system is depressurized before beginning any work. Handling, installation, and maintenance should be carried out with appropriate personal protective equipment to prevent injury.

Cummins Overview

Cummins is a company with a long history in the commercial truck industry, known for its wide range of products that include engines, powertrains, and components. The company has established a reputation for quality and reliability, with a commitment to innovation and customer satisfaction. Cummins’ product range is designed to meet the diverse needs of the commercial truck market, providing solutions that enhance the performance and efficiency of trucks.

Hydraulic Pump Support AR12780 Compatibility with Cummins Engines

The Hydraulic Pump Support AR12780, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This part is important for maintaining the structural integrity and operational efficiency of the hydraulic systems within these engines.

K38 and K50 Series Engines

The AR12780 Hydraulic Pump Support is compatible with the K38 and K50 series engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The AR12780 ensures that the hydraulic pump remains securely mounted, reducing the risk of mechanical failure and enhancing the overall durability of the engine.

KTA38GC CM558 and QSK38 CM2150 MCRS

For the KTA38GC CM558 and QSK38 CM2150 MCRS engines, the AR12780 Hydraulic Pump Support provides a critical mounting point for the hydraulic pump. These engines are typically used in applications requiring high power output and efficiency, such as marine and industrial settings. The AR12780’s design ensures that the hydraulic pump operates smoothly, contributing to the engine’s longevity and performance.

QSK50 Series Engines

The AR12780 Hydraulic Pump Support is also compatible with the QSK50 series engines, including the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 models. These engines are engineered for demanding environments, offering high power and reliability. The AR12780 ensures that the hydraulic pump is securely fastened, which is important for maintaining the engine’s operational integrity and preventing potential hydraulic system failures.

By providing a stable and reliable mounting solution, the AR12780 Hydraulic Pump Support enhances the performance and durability of these Cummins engines, ensuring they meet the rigorous demands of their respective applications.

Role of Part AR12780 Hydraulic Pump Support in Engine Systems

The AR12780 Hydraulic Pump Support is an integral component in the orchestration of various engine systems, ensuring seamless operation and efficiency. This support plays a significant role in the integration and functionality of several key components:

-

Drive and Accessory Systems: The AR12780 facilitates the secure mounting and operation of drive and accessory components. It ensures that these elements, which are essential for the engine’s auxiliary functions, are properly aligned and supported. This support is particularly important for components like the front gear train accessory, where precise alignment is necessary for optimal performance.

-

Auxiliary Pump: In systems where an auxiliary pump is employed, the AR12780 provides the necessary structural support. This is vital for maintaining the pump’s efficiency and longevity, as it ensures that the pump operates within its designed parameters without undue stress or misalignment.

-

EBM-Drive and Fuel System: The support offered by AR12780 is also extended to the EBM-drive and various fuel system accessories. It aids in the stable operation of these components, which are critical for the engine’s fuel management and delivery systems. This includes supporting the fuel pump and ensuring the integrity of the fuel transfer kit and its mounting.

-

Engine Mounting and Front Hydraulic Pump: AR12780 plays a role in the overall engine mounting system, particularly in relation to the front hydraulic pump. It helps in maintaining the pump’s position and operational efficiency, which is essential for the hydraulic aspects of the engine’s function.

-

Fuel Transfer Pump Mounting: The support is also crucial for the mounting of the fuel transfer pump. Proper support in this area ensures efficient fuel transfer, which is a key aspect of the engine’s fuel system.

In summary, the AR12780 Hydraulic Pump Support is a key element in the engine’s architecture, providing essential support and stability to a range of components. Its role in maintaining the alignment, efficiency, and longevity of these components is fundamental to the engine’s overall performance and reliability.

Conclusion

The AR12780 Hydraulic Pump Support is a critical component in the maintenance and operation of hydraulic systems in commercial trucks. Its robust design, compatibility with various Cummins engines, and role in supporting key engine components make it an essential part for ensuring the efficiency, reliability, and durability of truck operations. Regular maintenance, proper installation, and adherence to safety guidelines are important for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.