This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 212017 Pressure Switch is a component designed for use in commercial trucks. Manufactured by Cummins Inc., a company known for its robust and reliable engine and powertrain solutions, this part plays a role in ensuring the proper functioning of various systems within commercial trucks by monitoring and regulating pressure levels.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves when subjected to pressure changes, which then activates a mechanism to make or break an electrical connection. Pressure switches are commonly used in automotive systems to control functions such as engine oil pressure, fuel delivery, and brake systems, ensuring that these systems operate within safe and efficient parameters 1.

Role of the 212017 Pressure Switch in Truck Operation

The Cummins 212017 Pressure Switch is integral to the operation of commercial trucks. It monitors pressure levels within specific systems, such as the fuel or hydraulic systems, and sends signals to the truck’s control unit to adjust operations as necessary. By maintaining optimal pressure levels, the switch helps ensure the efficient and reliable performance of the truck’s systems, contributing to overall vehicle safety and performance.

Key Features of the 212017 Pressure Switch

The Cummins 212017 Pressure Switch is distinguished by several key features. Its design incorporates durable materials that can withstand the harsh conditions often encountered in commercial trucking. The switch also integrates advanced technology to provide accurate pressure readings and reliable operation. Additionally, its construction allows for easy installation and integration into existing truck systems.

Benefits of Using the 212017 Pressure Switch

Incorporating the Cummins 212017 Pressure Switch into truck systems offers several advantages. It enhances the efficiency of the truck’s operations by ensuring that systems operate at optimal pressure levels. This can lead to improved fuel efficiency and reduced wear on components. Furthermore, the switch’s reliable performance contributes to the overall reliability of the truck, minimizing the risk of system failures and downtime.

Installation and Integration

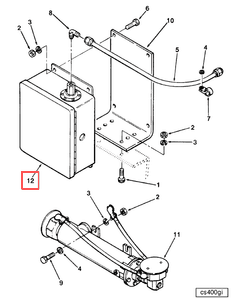

When installing the Cummins 212017 Pressure Switch, it is important to follow manufacturer guidelines to ensure proper integration into the truck’s systems. This may involve connecting the switch to the appropriate pressure lines and electrical circuits. It is also important to verify that the switch is compatible with the truck’s system and that all connections are secure to ensure accurate pressure readings and reliable operation.

Troubleshooting Common Issues

Common issues with pressure switches can include inaccurate pressure readings or failure to activate at the correct pressure levels. Troubleshooting the Cummins 212017 Pressure Switch may involve checking for obstructions in the pressure lines, verifying electrical connections, and ensuring the switch is properly calibrated. If problems persist, consulting the manufacturer’s troubleshooting guide or seeking professional assistance may be necessary.

Maintenance Tips

Regular maintenance of the Cummins 212017 Pressure Switch is important for ensuring its longevity and optimal performance. This may include periodic inspection of the switch and its connections, cleaning any debris from the pressure lines, and verifying that the switch is operating within specified parameters. Adhering to a maintenance schedule can help prevent issues and ensure the reliable operation of the truck’s systems.

Safety Considerations

When handling, installing, or maintaining the Cummins 212017 Pressure Switch, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, ensuring the truck’s systems are depressurized before working on the switch, and following all manufacturer guidelines and safety instructions. Adhering to these precautions can help prevent accidents and ensure the safe operation of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking applications.

Cummins Pressure Switch 212017 Compatibility

The Cummins Pressure Switch 212017 is a component designed to ensure the proper functioning of various engine systems by monitoring and regulating pressure levels. This pressure switch is compatible with a range of Cummins engines, ensuring seamless integration and reliable performance across different engine models.

Compatible Engines

- K19

- K38

- K50

- N14 MECHANICAL

- NH/NT 855

- QSK19 CM500

- V28

Grouping of Compatible Engines

The Cummins Pressure Switch 212017 is engineered to fit into the following groups of engines:

- K Series Engines: K19, K38, K50

- N Series Engines: N14 MECHANICAL, NH/NT 855

- QSK Series Engines: QSK19 CM500

- V Series Engines: V28

Integration and Functionality

The pressure switch is designed to integrate smoothly with the engine’s existing systems, providing essential feedback and control over pressure-related functions. Its compatibility across multiple engine series ensures that it can be used in a variety of applications, from industrial to heavy-duty transport, without requiring significant modifications.

Role of Part 212017 Pressure Switch in Engine Systems

The part 212017 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and efficiency. It is particularly significant in systems involving the Aid, Coolant Heater Starting, Cold Start Aid, Coolant Heater, Engine Coolant Heater, Kim Hot Start 460V.4000 W, Kim Hotstart 460V 8000 W, Kim Hotstart 460V.2500 W, Starting Aid, and Water Heater.

In the Coolant Heater Starting system, the Pressure Switch monitors the pressure levels within the coolant system. It ensures that the coolant reaches the necessary pressure before the engine starts, thus preventing potential damage from low-pressure conditions.

The Cold Start Aid system benefits from the Pressure Switch by maintaining the required pressure in the coolant during cold starts. This helps in achieving quicker engine warm-up, reducing wear and tear on engine components during startup.

In the Coolant Heater and Engine Coolant Heater systems, the Pressure Switch plays a role in regulating the pressure to ensure efficient heat transfer. This regulation is vital for maintaining the engine’s operating temperature, especially in colder climates.

For the Kim Hot Start 460V.4000 W, Kim Hotstart 460V 8000 W, and Kim Hotstart 460V.2500 W systems, the Pressure Switch ensures that the heating elements operate within safe pressure limits. This is essential for the longevity and reliability of these high-power heating systems.

In the Starting Aid system, the Pressure Switch helps in maintaining the necessary pressure conditions for a smooth engine start. This is particularly important in systems where starting conditions can be challenging due to environmental factors.

Lastly, in the Water Heater system, the Pressure Switch ensures that the water reaches the optimal pressure before heating, thus enhancing the efficiency and safety of the heating process.

Overall, the part 212017 Pressure Switch is a key component in these systems, ensuring that pressure levels are maintained within safe and efficient operating ranges.

Conclusion

The Cummins 212017 Pressure Switch is a vital component in the operation of commercial trucks and various engine systems. Its role in monitoring and regulating pressure levels ensures the efficient and reliable performance of these systems, contributing to overall vehicle safety and performance. With its durable design, advanced technology, and compatibility across multiple engine models, the 212017 Pressure Switch is a reliable choice for maintaining optimal pressure levels in commercial trucking applications.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.