This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3408606 Pressure Switch is a component designed to monitor and regulate pressure within a truck’s system. Its purpose is to ensure that the system operates within specified pressure parameters, thereby contributing to the overall efficiency and reliability of the vehicle. This switch plays a role in maintaining optimal performance and preventing potential issues related to pressure fluctuations.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a certain fluid pressure threshold. It operates by using a diaphragm or piston mechanism that moves when subjected to pressure changes, thereby activating or deactivating the switch. Pressure switches are commonly used in various automotive systems to control operations based on pressure levels, ensuring that systems function within safe and efficient parameters 1.

Role of the 3408606 Pressure Switch in Truck Operation

The Cummins 3408606 Pressure Switch is integral to the operation of commercial trucks. It monitors the pressure within specific systems, such as the fuel or hydraulic systems, and signals other components to adjust operations accordingly. This switch works in conjunction with sensors, control modules, and actuators to maintain system balance and respond to changing conditions. Its role is vital in ensuring that the truck’s systems operate smoothly and efficiently 2.

Key Features of the 3408606 Pressure Switch

The Cummins 3408606 Pressure Switch is characterized by its robust design and high-quality materials, which ensure durability and reliable performance. It features precise pressure sensing technology that allows for accurate monitoring and control. The switch is engineered to withstand the harsh conditions typical of commercial truck environments, providing consistent operation over time.

Benefits of Using the 3408606 Pressure Switch

Incorporating the Cummins 3408606 Pressure Switch into a truck’s system offers several advantages. It enhances system performance by ensuring that pressure levels are maintained within optimal ranges. This leads to improved efficiency and reliability, reducing the likelihood of system failures or inefficiencies. Additionally, the switch contributes to the overall longevity of the truck’s components by preventing damage caused by pressure fluctuations 3.

Installation and Integration

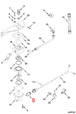

Proper installation of the Cummins 3408606 Pressure Switch is crucial for its effective operation. It should be installed in accordance with the manufacturer’s guidelines, ensuring that it is correctly positioned within the system and connected to the appropriate electrical and fluid lines. Integration with other components requires careful attention to ensure compatibility and proper function within the truck’s system.

Troubleshooting and Maintenance

Common issues with pressure switches may include inaccurate readings, failure to activate or deactivate, or physical damage. Troubleshooting steps involve checking the switch’s connections, inspecting for damage, and testing its operation under various pressure conditions. Regular maintenance, such as cleaning and inspecting for wear, can help ensure the switch’s optimal performance and longevity.

Safety Considerations

When working with the Cummins 3408606 Pressure Switch, it is important to observe safety guidelines. This includes ensuring that the truck’s system is depressurized before beginning any work, using appropriate personal protective equipment, and following all manufacturer recommendations for handling, installation, and maintenance. Adhering to these safety practices helps protect both the technician and the equipment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of modern transportation. The company’s commitment to innovation, quality, and customer satisfaction has solidified its position as a leader in the field.

Cummins Pressure Switch 3408606 in Engine Applications

The Cummins Pressure Switch 3408606 is a critical component in various engine systems, ensuring optimal performance and safety. This part is integral to the engine’s operation, particularly in managing pressure-related functions. Below is a detailed description of how this pressure switch fits into the engines it supports.

K19 Engine Series

The K19 engine series is renowned for its robust design and reliability, often used in heavy-duty applications. The Pressure Switch 3408606 plays a pivotal role in these engines by:

- Monitoring Pressure Levels: It ensures that the engine operates within safe pressure limits, preventing potential damage from over-pressurization.

- Controlling Fuel Delivery: By regulating the fuel delivery system, it helps maintain consistent engine performance.

- Enhancing Safety: It acts as a fail-safe mechanism, shutting down the engine if abnormal pressure levels are detected, thereby preventing accidents.

Grouping of Applications

The Pressure Switch 3408606 is not limited to a single engine model but is compatible with a range of Cummins engines. Here’s how it fits into different engine groups:

- Industrial Engines: In industrial settings, this switch is crucial for maintaining the efficiency of large machinery, ensuring that pressure-related issues do not lead to downtime.

- Commercial Vehicles: For commercial vehicles, the pressure switch helps in maintaining optimal engine performance under varying load conditions, contributing to the vehicle’s reliability and longevity.

- Marine Engines: In marine applications, the switch ensures that the engine operates smoothly in harsh environments, providing the necessary pressure regulation to withstand the rigors of maritime conditions.

By integrating seamlessly into these engine systems, the Cummins Pressure Switch 3408606 ensures that the engines perform reliably and safely across various applications.

Role of Part 3408606 Pressure Switch in Engine Systems

The part 3408606 Pressure Switch is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. It operates by monitoring and regulating the pressure within the system, thereby facilitating seamless interaction between different components.

In the context of injectors, the Pressure Switch plays a significant role in maintaining the precise pressure levels required for fuel delivery. This ensures that the injectors operate within their specified parameters, contributing to efficient fuel combustion and overall engine performance.

When considering valve operation, the Pressure Switch aids in the modulation of pressure, which is essential for the timely and accurate opening and closing of valves. This is particularly important in engines where valve timing is electronically controlled, as it ensures that the valves respond appropriately to the engine’s operational demands.

In terms of timing control, the Pressure Switch contributes to the synchronization of various engine cycles. By maintaining consistent pressure levels, it helps in ensuring that the engine’s timing mechanisms, such as the camshaft and crankshaft, operate in harmony. This is vital for the engine’s smooth operation and longevity.

Overall, the part 3408606 Pressure Switch is a key player in the intricate dance of engine components, facilitating their interaction and ensuring that the engine operates at peak efficiency.

Conclusion

The Cummins 3408606 Pressure Switch is a vital component in the operation of commercial trucks and various engine systems. Its role in monitoring and regulating pressure ensures optimal performance, efficiency, and safety. Proper installation, regular maintenance, and adherence to safety guidelines are essential for the effective operation of this Cummins part. By understanding its features, benefits, and applications, technicians and operators can ensure the longevity and reliability of their vehicles and equipment.

-

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.