Introduction

The Cummins 3408612 Pressure Switch is a component designed to monitor and regulate pressure within specific systems of commercial trucks. Its role is significant in ensuring the efficient and safe operation of these vehicles. By providing precise pressure readings and actuating controls based on these readings, the switch contributes to the overall performance and reliability of the truck 1.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes an electrical circuit in response to a specific pressure threshold. It functions by using a diaphragm or piston that moves in response to changes in pressure, which in turn activates a switch mechanism. Pressure switches are commonly used in various systems, including hydraulic, pneumatic, and fuel systems, to monitor and control pressure levels 2.

Purpose of the 3408612 Pressure Switch

The Cummins 3408612 Pressure Switch is specifically designed to monitor and control pressure within the truck’s fuel system. It plays a role in ensuring that the fuel system operates within safe and efficient pressure ranges. By doing so, it helps maintain optimal fuel delivery, which is crucial for the engine’s performance and longevity 3.

Key Features

The Cummins 3408612 Pressure Switch is characterized by its robust design and high-quality materials. It is constructed to withstand the demanding conditions of commercial truck operations. Key features include a durable housing, precision-machined components, and a reliable switching mechanism. These attributes contribute to its accuracy and longevity.

Benefits of Using the 3408612 Pressure Switch

Utilizing the Cummins 3408612 Pressure Switch offers several advantages. It enhances the performance of the fuel system by ensuring consistent pressure levels, which leads to improved engine efficiency. Additionally, its reliable operation contributes to the overall reliability of the truck, reducing the likelihood of system failures and enhancing safety.

Installation and Integration

Proper installation of the Cummins 3408612 Pressure Switch is vital for its effective operation. It should be integrated into the truck’s fuel system according to the manufacturer’s guidelines. This includes ensuring that all connections are secure and that the switch is correctly positioned to accurately monitor pressure. Special considerations may include verifying system compatibility and conducting preliminary checks to ensure the system is ready for integration.

Troubleshooting Common Issues

Common issues with the Cummins 3408612 Pressure Switch may include inaccurate pressure readings or failure to actuate. Troubleshooting steps involve checking the switch’s connections, verifying the integrity of the diaphragm or piston, and ensuring that the electrical circuit is functioning correctly. Diagnostic tips may include using a multimeter to test electrical continuity and inspecting the switch for physical damage.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3408612 Pressure Switch, regular maintenance is recommended. This includes periodic inspection of the switch for signs of wear or damage, cleaning the switch to remove any debris, and verifying that all connections remain secure. Regular servicing can help prevent issues and ensure the switch continues to operate effectively.

Safety Considerations

When working with the Cummins 3408612 Pressure Switch, it is important to observe safety guidelines to prevent accidents. This includes ensuring that the truck’s engine is turned off and that all pressure has been relieved from the system before beginning any work. Additionally, using appropriate personal protective equipment (PPE) and following manufacturer instructions can help ensure safe operation and maintenance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding needs of commercial transportation.

Cummins Pressure Switch 3408612 Compatibility

The Cummins Pressure Switch part number 3408612 is designed to integrate seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This pressure switch is engineered to fit within the engine systems of the following models:

- 4B3.9 and 6B5.9 Engines

These engines, part of the Cummins B series, are known for their robust construction and efficiency. The 3408612 pressure switch is specifically tailored to work with these engines, providing precise control over the engine’s pressure systems. Its compatibility with these models ensures that the switch can effectively monitor and regulate pressure, contributing to the overall health and longevity of the engine.

- 6C8.3 Engine

The 6C8.3 engine, another member of the Cummins C series, also benefits from the integration of the 3408612 pressure switch. This engine is recognized for its power and reliability, and the pressure switch plays a crucial role in maintaining the engine’s performance by ensuring that pressure levels remain within the optimal range. The switch’s compatibility with the 6C8.3 engine underscores its versatility and effectiveness across different engine types.

By ensuring compatibility with these engines, the Cummins Pressure Switch 3408612 provides a reliable solution for maintaining engine pressure, contributing to the overall efficiency and durability of the engine systems.

Role of Part 3408612 Pressure Switch in Engine Systems

The Part 3408612 Pressure Switch is integral to the functionality and safety of various engine systems. It is primarily responsible for monitoring and regulating pressure within the engine, ensuring optimal performance and preventing potential damage.

Integration with Engine Components

-

Connecting Rod and Piston: The Pressure Switch indirectly supports the connecting rod and piston by maintaining the appropriate oil pressure. This ensures that these components receive adequate lubrication, reducing friction and wear.

-

Coolant Pressure Switch: While distinct from the coolant system, the Part 3408612 Pressure Switch works in conjunction with the coolant pressure switch to maintain overall engine health. Proper pressure management helps in efficient heat dissipation, protecting the engine from overheating.

-

Engine Monitoring System: The Pressure Switch feeds real-time data to the engine monitoring system. This allows for continuous assessment of pressure levels, enabling the system to make necessary adjustments to maintain engine efficiency.

-

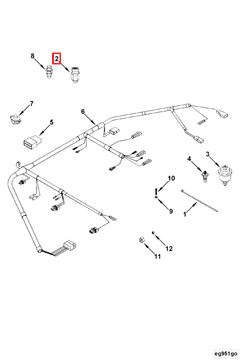

Engine Wiring: The Pressure Switch is connected to the engine wiring harness, which facilitates the transmission of pressure data to other engine components and systems. This integration ensures that the engine operates within safe parameters.

-

Instrumentation: The data from the Pressure Switch is often displayed on the engine’s instrumentation panel. This provides engineers and mechanics with vital information about the engine’s pressure status, aiding in diagnostics and maintenance.

-

Oil Block Connection: The Pressure Switch is typically mounted near the oil block connection. This strategic placement allows it to accurately monitor oil pressure, ensuring that the oil system functions correctly.

-

Oil Pressure Sensor: Working alongside the oil pressure sensor, the Pressure Switch helps in providing a comprehensive overview of the oil pressure within the engine. This dual monitoring system enhances the reliability of pressure readings.

-

Oil Pressure Switch: Similar to the oil pressure switch, the Part 3408612 Pressure Switch plays a role in activating or deactivating certain engine functions based on oil pressure levels. This helps in preventing engine damage due to low oil pressure.

-

Press Transfer Mounting: The Pressure Switch is often mounted using press transfer techniques. This ensures a secure and stable installation, which is essential for accurate pressure readings.

-

Switch: As a switch, it can trigger alarms or shut down the engine if pressure levels fall outside the safe range. This protective function is vital for the longevity and safety of the engine.

-

Low Oil Pressure: Specifically, the Pressure Switch is designed to detect low oil pressure conditions. When such conditions are detected, it can signal the engine control unit to take corrective actions, such as adjusting the oil pump or alerting the operator.

-

Wiring Harness: The Pressure Switch is an essential component of the wiring harness, connecting various pressure-sensitive points within the engine. This network ensures that all pressure-related data is accurately conveyed to the engine’s control systems.

Conclusion

The Cummins 3408612 Pressure Switch is a critical component in the maintenance and operation of commercial truck engines. Its role in monitoring and regulating pressure ensures the efficient and safe operation of the engine, contributing to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and adherence to safety guidelines are essential for the effective operation of this Cummins part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Tom Denton and Hayley Pells. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Bruce Maclaurin. (2018). High Speed Off-Road Vehicles. Wiley.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.