This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3978308 Stop Switch is a critical component designed for use in commercial trucks, facilitating the safe and efficient shutdown of the engine. Understanding its purpose and operation is essential for maintaining vehicle safety and performance 1.

Basic Concepts of a Stop Switch

A stop switch is an electrical device that allows the operator to interrupt the power supply to the engine, thereby stopping its operation. This function is vital for the safe operation of the vehicle, allowing the operator to have direct control over the engine’s status 2.

Role of the 3978308 Stop Switch in Truck Operation

The Cummins 3978308 Stop Switch integrates into the truck’s electrical and engine management systems by providing a direct link between the operator and the engine’s power supply. When activated, it interrupts the electrical circuit that powers the engine, leading to a safe and efficient shutdown. This process is designed to be immediate, allowing for quick response in situations where engine operation needs to be halted 3.

Key Features

The Cummins 3978308 Stop Switch is characterized by several design elements and materials that enhance its performance and reliability. It is constructed from durable materials to withstand the rigors of commercial truck operation. The switch’s design includes features that ensure a secure and reliable connection within the truck’s electrical system, minimizing the risk of accidental disconnection or failure. Additionally, it may incorporate technological aspects such as corrosion resistance and enhanced electrical conductivity, which contribute to its overall performance and longevity.

Benefits

Utilizing the Cummins 3978308 Stop Switch offers several advantages. It contributes to improved safety by providing a reliable method for engine shutdown, which is crucial in emergency situations. The switch’s design and integration into the truck’s systems also enhance the reliability of the shutdown process, ensuring that the engine can be stopped efficiently whenever necessary. Furthermore, its ease of use for the operator simplifies the process of engine management, contributing to overall operational efficiency.

Troubleshooting and Maintenance

Common issues with the Cummins 3978308 Stop Switch may include electrical faults or physical damage to the switch itself. Troubleshooting these problems involves checking the electrical connections for integrity and ensuring that the switch is securely mounted and functioning correctly. Regular maintenance, such as inspecting the switch for signs of wear or damage and ensuring that all connections are clean and tight, can help prevent issues and ensure the switch’s longevity and optimal performance.

Application in Engines

QSB5.9 CM850 and QSC8.3 CM850 (CM2850)

The Stop Switch part number 3978308 is integral to the QSB5.9 CM850 and QSC8.3 CM850 (CM2850) engines. These engines are known for their robust performance and reliability in various applications, from agricultural to industrial use. The Stop Switch ensures that the engine can be quickly and safely brought to a halt, which is crucial for maintenance and emergency situations.

QSM11 CM570

Similarly, the QSM11 CM570 engine also utilizes the Stop Switch part number 3978308. This engine is designed for heavy-duty applications, and the Stop Switch plays a vital role in maintaining operational safety and control. Its design allows for easy access and operation, ensuring that the engine can be stopped promptly when needed.

Functionality and Importance

The Stop Switch is a fundamental safety feature that provides a manual override to stop the engine. This is particularly important in situations where the engine needs to be stopped immediately, such as in the event of a malfunction or emergency. The switch is designed to be easily accessible and operable, ensuring that it can be used effectively in any scenario.

Installation and Integration

The Stop Switch is integrated into the engine’s control system, allowing for seamless operation. It is typically mounted in a location that is easily reachable by the operator, ensuring that it can be activated quickly when necessary. The switch is designed to work in conjunction with the engine’s electrical system, providing a reliable means of stopping the engine.

Reliability and Durability

Cummins is known for producing high-quality, durable components, and the Stop Switch part number 3978308 is no exception. It is designed to withstand the rigors of heavy-duty use, providing reliable operation over an extended period. This ensures that the engine can be safely stopped whenever required, contributing to overall operational safety and efficiency.

Role of Part 3978308 Stop Switch in Engine Systems

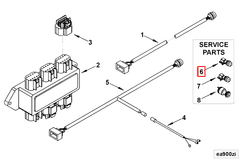

Integration with the Harness

The Stop Switch is connected to the main harness, which serves as the primary electrical conduit for the engine system. This connection allows the Stop Switch to communicate with the engine control unit (ECU) and other critical systems. When activated, the Stop Switch sends a signal through the harness to the ECU, instructing it to cut off fuel supply and stop the engine. This immediate response is essential for emergency shutdowns or routine stops.

Main Extension Harness

In more complex engine systems, the Stop Switch may also interface with the main extension harness. This harness extends the reach of the primary electrical system, allowing the Stop Switch to be positioned in various locations for optimal accessibility. The main extension harness ensures that the Stop Switch can be easily reached by the operator, enhancing safety and convenience.

Secondary Instrument Panel

The Stop Switch is often linked to the secondary instrument panel, which houses additional controls and indicators. This connection allows the Stop Switch to interact with other instruments and gauges, providing a comprehensive overview of the engine’s status. For instance, when the Stop Switch is activated, it may trigger warning lights or alarms on the secondary instrument panel, alerting the operator to the engine shutdown.

Wiring Harness

Finally, the Stop Switch is integrated into the overall wiring harness of the engine system. The wiring harness is a network of cables and connectors that link all electrical components within the engine. This integration ensures that the Stop Switch can effectively communicate with all parts of the engine system, from the ECU to the fuel injection system, guaranteeing a smooth and controlled shutdown process.

Conclusion

The Cummins 3978308 Stop Switch plays a significant role in the safe and efficient operation of engine systems by interfacing with the main harness, main extension harness, secondary instrument panel, and wiring harness. Its reliable performance ensures that the engine can be stopped promptly and safely when needed.

-

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.