4924925

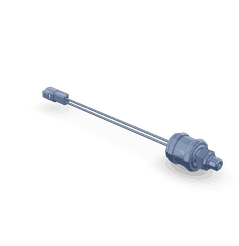

Pressure Switch

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4924925 Pressure Switch is a component designed for use in heavy-duty truck systems. Its purpose is to monitor and regulate pressure within specific systems, ensuring that operations remain within safe and efficient parameters. This switch plays a role in maintaining the performance and reliability of the truck’s systems by providing accurate pressure readings and facilitating timely responses to pressure changes 1.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves in response to changes in pressure. When the pressure reaches a predetermined level, the diaphragm or piston activates a mechanism that either opens or closes the electrical circuit. Pressure switches are commonly used in automotive systems to control various functions, such as activating pumps, regulating fluid flow, and ensuring safety by preventing over-pressurization 2.

Role of the 4924925 Pressure Switch in Truck Operation

The Cummins 4924925 Pressure Switch performs several functions within a truck’s system. It monitors pressure levels in critical areas, such as the fuel system or hydraulic circuits. When the pressure exceeds or falls below the set threshold, the switch sends a signal to the truck’s control system, which can then take appropriate action. This may include adjusting the pressure, alerting the driver, or shutting down the system to prevent damage. The switch interacts with other components, such as sensors, control modules, and actuators, to maintain optimal system performance 3.

Key Features of the 4924925 Pressure Switch

The Cummins 4924925 Pressure Switch is characterized by several key features that enhance its performance. Its design includes a robust housing that protects internal components from environmental factors. The switch utilizes high-quality materials to ensure durability and reliability under varying conditions. Additionally, it features precise calibration to provide accurate pressure readings, and its compact design allows for easy integration into existing systems.

Benefits of Using the 4924925 Pressure Switch

The Cummins 4924925 Pressure Switch offers several advantages. Its reliable performance ensures that pressure levels are consistently monitored and maintained, contributing to the overall efficiency of the truck’s systems. The switch’s accurate readings help prevent issues related to over- or under-pressurization, enhancing safety and reducing the risk of system failures. Additionally, its durable construction and precise calibration provide long-term reliability, making it a valuable component for heavy-duty applications.

Installation and Integration

Installing the Cummins 4924925 Pressure Switch involves several steps to ensure proper integration into the truck’s system. First, the system must be prepared by ensuring that all connections are clean and free from debris. The switch should be mounted in a location that allows for easy access and accurate pressure readings. Electrical connections must be securely made, following the manufacturer’s guidelines to prevent issues. Once installed, the system should be tested to confirm that the switch is functioning correctly and providing accurate readings.

Troubleshooting and Maintenance

Common issues with the Cummins 4924925 Pressure Switch may include inaccurate readings, failure to activate, or electrical problems. Diagnostic procedures involve checking electrical connections, verifying pressure levels, and inspecting the switch for physical damage. Regular maintenance, such as cleaning connections and verifying calibration, can help ensure the longevity and optimal performance of the switch. If issues persist, consulting the manufacturer’s guidelines or seeking professional assistance is recommended.

Safety Considerations

When working with the Cummins 4924925 Pressure Switch, several safety practices should be observed. Ensure that the truck’s system is depressurized before beginning any work to prevent injury from sudden pressure release. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines for installation, maintenance, and troubleshooting to ensure safe and effective operation of the switch.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the automotive and heavy-duty truck industry. The company offers a wide range of products and services designed to meet the needs of various applications, from on-highway trucks to off-highway construction equipment. Cummins is known for its commitment to customer satisfaction, technological advancement, and sustainable practices.

Cummins Pressure Switch 4924925 Compatibility with Engine Models

The Cummins Pressure Switch 4924925 is designed to integrate seamlessly with a variety of engine models, ensuring reliable performance and compatibility across different applications. This pressure switch is engineered to fit within the operational parameters of several Cummins engine series, providing essential functionality for maintaining system pressure and operational integrity.

K38 and K50 Engines

The Pressure Switch 4924925 is compatible with the K38 and K50 engines. These engines are known for their robust design and efficiency, making them suitable for a range of heavy-duty applications. The pressure switch ensures that the operational pressure within these engines remains within the specified limits, contributing to the overall reliability and performance of the engine.

QSK38 and QSK50 Engines

For the QSK38 and QSK50 engines, the Pressure Switch 4924925 is engineered to fit perfectly within the engine’s pressure management system. These engines, part of the QSK series, are designed for high-performance applications, and the pressure switch plays a crucial role in maintaining the necessary pressure levels to ensure optimal engine operation.

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

QSK45 and QSK60 Engines

The Pressure Switch 4924925 is also compatible with the QSK45 and QSK60 engines. These engines are part of the QSK series and are known for their versatility and efficiency. The pressure switch ensures that the engine’s pressure systems operate within the required parameters, contributing to the engine’s overall performance and longevity.

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60 G CM2358 K110

QSK78 and QSK95 Engines

The Pressure Switch 4924925 is designed to fit the QSK78 and QSK95 engines, which are part of the QSK series and are known for their high power output and reliability. The pressure switch ensures that these engines maintain the necessary pressure levels, contributing to their performance and durability.

- QSK78 CM500

- QSK95 CM2350 K111

- QSK95 CM2350 K113

QST30 Engines

The Pressure Switch 4924925 is also compatible with the QST30 engines, ensuring that these engines maintain the required pressure levels for optimal performance. The QST30 engines are part of the QST series and are designed for specific applications where reliability and performance are critical.

- QST30 CM2350 T101

- QST30 CM552

This compatibility ensures that the Pressure Switch 4924925 can be used across a wide range of Cummins engine models, providing a reliable and efficient solution for maintaining system pressure.

Role of Part 4924925 Pressure Switch in Engine Systems

The Part 4924925 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and safety. Its primary function is to monitor and regulate pressure within the system, triggering actions based on pressure thresholds.

Integration with Engine Components

-

Engine Lubrication Primer: The pressure switch works in conjunction with the engine lubrication primer to ensure that the correct pressure is maintained in the lubrication system. This is essential for the proper circulation of lubricants, reducing wear and tear on engine components.

-

Filter and Fuel Pump Oil Module: Within the fuel system, the pressure switch is connected to the filter and fuel pump oil module. It helps in maintaining the necessary pressure for efficient fuel delivery, which is vital for consistent engine performance.

-

Engine Control and Motor Starting Systems: The pressure switch is also integrated into the engine control and motor starting systems. It provides feedback to the engine control unit (ECU) about the pressure status, allowing the ECU to make adjustments to the motor starting sequence for smooth engine ignition.

-

Plumbing and Lub Oil Prim Pump: In the plumbing arrangement of the engine, the pressure switch is placed to monitor the pressure in the lubrication oil priming pump. This ensures that the pump operates within safe pressure limits, preventing damage to the pump and associated components.

-

Pressure Switch Kit and Primer: When part of a pressure switch kit, it collaborates with other primer components to maintain system integrity. This setup is particularly important in high-pressure environments where precise pressure management is required.

-

Engine Lubricating Service Kit: Included in the engine lubricating service kit, the pressure switch helps in diagnosing and preventing issues related to pressure fluctuations. This proactive approach aids in extending the lifespan of the engine and its components.

Conclusion

In summary, the Part 4924925 Pressure Switch plays a significant role in various engine systems by ensuring that pressure levels are consistently monitored and regulated. This not only enhances the efficiency of the engine but also contributes to its longevity and reliability.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.