This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4927365 Pressure Switch is a component designed for use in commercial trucks. Manufactured by Cummins Inc., a well-established name in the automotive and heavy-duty truck industry, this part is integral to the efficient operation of truck systems.

Basic Concepts of Pressure Switches

A pressure switch is a device that opens or closes electrical circuits in response to a specific pressure threshold. It operates by using a diaphragm or piston that moves in response to changes in pressure, which then activates a switch mechanism. Pressure switches are commonly used in various automotive systems to monitor and control fluid or air pressure, ensuring that systems operate within safe and efficient parameters 1.

Purpose of the Cummins 4927365 Pressure Switch

The Cummins 4927365 Pressure Switch plays a specific role in the operation of commercial trucks by monitoring and controlling pressure within certain systems. It is designed to ensure that the pressure levels remain within a predetermined range, which is crucial for the proper functioning of the truck’s systems. This switch can be found in applications such as brake systems, where it helps maintain the necessary pressure for safe and effective braking, and in other systems where pressure regulation is required 2.

Key Features

The Cummins 4927365 Pressure Switch is characterized by several key features that enhance its functionality. Its design incorporates durable materials that can withstand the harsh conditions typical of commercial truck environments. The switch is engineered for precision, ensuring accurate pressure readings and reliable operation. Additionally, it may include unique attributes such as corrosion resistance and the ability to operate under a wide range of temperatures, which contribute to its effectiveness in demanding applications 3.

Benefits

The advantages provided by the Cummins 4927365 Pressure Switch include improved system performance, reliability, and efficiency in truck operations. By ensuring that pressure levels are maintained within the desired range, this switch helps prevent system failures and enhances the overall performance of the truck. Its reliable operation contributes to the safety and efficiency of the vehicle, making it a valuable component in commercial truck systems 4.

Installation and Integration

Installing and integrating the Cummins 4927365 Pressure Switch into truck systems requires adherence to specific guidelines to ensure proper setup. This may involve connecting the switch to the appropriate pressure lines and electrical circuits, following manufacturer recommendations for installation. It is important to consider any prerequisites, such as system pressure requirements and electrical compatibility, to ensure the switch functions correctly within the truck’s system.

Troubleshooting and Maintenance

Identifying common issues with the Cummins 4927365 Pressure Switch and performing diagnostic procedures are important for maintaining its optimal performance. Regular maintenance practices, such as checking for signs of wear or damage and ensuring proper connections, can help ensure the longevity and reliability of the switch. Troubleshooting may involve testing the switch’s operation and verifying that it activates at the correct pressure threshold.

Safety Considerations

When working with the Cummins 4927365 Pressure Switch, it is important to follow safety guidelines and precautions. This includes handling the switch with care to avoid damage, ensuring proper installation to prevent system malfunctions, and adhering to maintenance procedures to maintain its functionality. Safety measures should also be taken when working with pressurized systems to avoid injury or damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Compatibility with Engine Models

The Cummins Pressure Switch 4927365 is designed to ensure the proper functioning of various engine systems by monitoring and regulating pressure levels. This pressure switch is compatible with several Cummins engine models, providing a reliable solution for maintaining optimal engine performance.

Compatible Engine Models

-

K38 and K50 Engines

- The K38 and K50 engines benefit from the precise pressure regulation offered by the 4927365 pressure switch. This ensures that the engine operates within safe pressure limits, enhancing longevity and efficiency.

-

QSK19 CM850 MCRS and QSK50 CM2150 K107 Engines

- For the QSK19 CM850 MCRS and QSK50 CM2150 K107 engines, the 4927365 pressure switch plays a vital role in maintaining the balance of pressure within the engine’s systems. This compatibility ensures that these high-performance engines can operate at peak efficiency while minimizing the risk of pressure-related issues.

-

QSK50 CM2150 MCRS and QSK60 CM850 MCRS Engines

- The QSK50 CM2150 MCRS and QSK60 CM850 MCRS engines also integrate seamlessly with the 4927365 pressure switch. This compatibility is crucial for these engines, as it helps in maintaining the intricate balance of pressure required for their operation, ensuring reliability and performance.

By ensuring that the 4927365 pressure switch is compatible with these engine models, Cummins provides a reliable solution for maintaining the integrity and efficiency of these engines.

Role of Part 4927365 Pressure Switch in Engine Systems

The Part 4927365 Pressure Switch is an integral component in various engine systems, ensuring optimal performance and safety. Its primary function is to monitor and regulate pressure levels within the engine, which is essential for maintaining efficient operation.

Integration with Alarm Systems

When integrated with alarm systems, the Pressure Switch detects abnormal pressure fluctuations. Upon detection, it triggers the alarm, alerting operators to potential issues before they escalate. This proactive approach helps in preventing engine damage and ensures timely maintenance.

Interaction with Engine Instrument Panels

In engine instrument panels, the Pressure Switch provides real-time data on pressure levels. This information is vital for operators to make informed decisions regarding engine load and performance adjustments. The switch ensures that the displayed readings are accurate, contributing to effective engine management.

Role in Engine Monitoring Systems

Within engine monitoring systems, the Pressure Switch continuously monitors pressure conditions. It sends signals to the monitoring system, which analyzes the data to detect trends or anomalies. This capability allows for predictive maintenance, reducing the likelihood of unexpected failures.

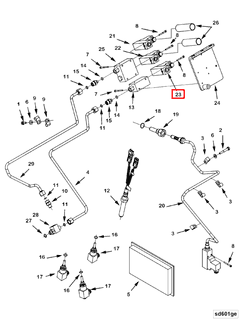

Connection to Sensor Brackets

The Pressure Switch is often mounted on sensor brackets, which provide a stable and secure location for the switch. This setup ensures that the switch can accurately measure pressure without being affected by engine vibrations or movements.

Contribution to Overall System Efficiency

By maintaining consistent pressure levels, the Pressure Switch contributes to the overall efficiency of the engine system. It helps in optimizing fuel consumption and reducing emissions, aligning with environmental and operational goals.

Enhancing Safety Protocols

Incorporating the Pressure Switch into safety protocols enhances the reliability of engine systems. It acts as a safeguard against pressure-related failures, ensuring that the engine operates within safe parameters. This integration is particularly important in high-stress environments where engine reliability is paramount.

Conclusion

The Cummins 4927365 Pressure Switch plays a significant role in various engine systems by ensuring pressure levels are maintained within safe and efficient ranges. Its integration with alarm systems, engine instrument panels, engine monitoring systems, and sensor brackets highlights its importance in modern engine management.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.