This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

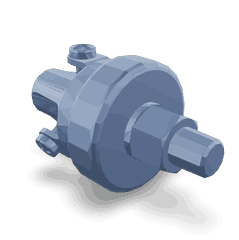

The Cummins 4984879 Pressure Switch is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Pressure Switches

A pressure switch is a device that detects changes in pressure within a system and activates or deactivates electrical circuits in response. These switches are commonly used in various automotive applications to monitor and control systems such as fuel delivery, air conditioning, and engine management. They operate based on a set pressure threshold, which, when reached, triggers the switch to change its state, thereby controlling the flow of electricity to connected components 1.

Purpose of the Cummins 4984879 Pressure Switch

This Cummins part plays a role in the operation of a truck by monitoring specific pressure levels within the system. It is integrated into the truck’s systems to ensure that components operate within safe and efficient parameters. By detecting pressure changes, it helps in maintaining the optimal performance of the truck’s engine and other critical systems 2.

Key Features

The 4984879 Pressure Switch is characterized by several key features that enhance its functionality and durability. These include a robust design that ensures reliable operation under varying conditions, the use of high-quality materials to withstand the rigors of commercial truck environments, and precise engineering to accurately detect pressure changes. Additionally, it may feature unique characteristics such as adjustable pressure settings or sealed construction to prevent contamination 3.

Benefits

The 4984879 Pressure Switch offers several benefits that contribute to improved system performance, reliability, and efficiency. By accurately monitoring and controlling pressure levels, it helps in preventing system failures and ensuring that components operate within their designed parameters. This leads to enhanced truck performance, reduced maintenance needs, and increased operational efficiency.

Installation

Proper installation of the 4984879 Pressure Switch is crucial for its effective operation. Installation guidelines typically include ensuring the switch is correctly positioned within the system, securing it in place to prevent movement, and verifying electrical connections are secure and correct. Special considerations may include system-specific requirements or the need for system purging before installation.

Troubleshooting

Common issues with the 4984879 Pressure Switch may include inaccurate pressure readings, failure to activate or deactivate, or electrical faults. Troubleshooting steps often involve checking electrical connections, verifying pressure levels within the system, and testing the switch’s operation. Identifying and addressing the root cause of issues is key to restoring proper function.

Maintenance

Recommended maintenance practices for the 4984879 Pressure Switch include regular inspection for signs of wear or damage, testing its operation to ensure accurate pressure detection, and cleaning or replacing the switch if necessary. Adhering to these practices helps in ensuring the longevity and optimal performance of the switch.

Safety Considerations

When working with the 4984879 Pressure Switch, it is important to observe safety guidelines and precautions. This includes ensuring the truck’s system is depressurized before beginning work, using appropriate personal protective equipment, and following electrical safety practices to prevent injury or damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. Its product range includes engines, powertrain components, and aftermarket parts, serving a wide array of industries and applications.

Cummins Pressure Switch 4984879 in Engine Applications

The Cummins Pressure Switch 4984879 is a critical component in various engine systems, ensuring optimal performance and safety. This pressure switch is designed to monitor and regulate the pressure levels within the engine’s system, providing essential feedback to the engine control unit (ECU).

In the 6B5.9 engine, the pressure switch 4984879 plays a pivotal role in maintaining the integrity of the engine’s operation. It is typically integrated into the engine’s fuel system, where it monitors the pressure of the fuel being supplied to the engine. This ensures that the fuel is delivered at the correct pressure, which is vital for efficient combustion and overall engine performance.

The pressure switch 4984879 is also used in other Cummins engines, where it serves a similar function. In these applications, the pressure switch helps to maintain the balance between fuel delivery and engine demand, preventing issues such as over-pressurization or fuel starvation. This component is essential for the smooth operation of the engine and helps to prevent potential failures that could arise from improper pressure levels.

Role of Part 4984879 Pressure Switch in Engine Systems

The part 4984879 Pressure Switch is an integral component in the regulation and monitoring of various engine systems. It operates by detecting changes in pressure within the system and generating a signal in response. This signal is then utilized by the device to make necessary adjustments, ensuring optimal performance and safety.

Integration with Oil Pressure Systems

In oil pressure systems, the 4984879 Pressure Switch works in conjunction with the oil pressure sensor to monitor the pressure levels of the engine oil. When the pressure falls below or exceeds the predetermined thresholds, the switch activates, sending a signal to the device. This signal prompts the device to take corrective actions, such as adjusting the oil pump or alerting the operator, thereby maintaining the oil pressure within the desired range.

Signal Generating Capabilities

The signal generating function of the 4984879 Pressure Switch is essential for the real-time monitoring and control of engine systems. By converting pressure changes into electrical signals, it enables the device to respond promptly to variations in system conditions. This capability is particularly important in dynamic environments where pressure levels can fluctuate rapidly.

Coordination with Other Switches

The 4984879 Pressure Switch often works in coordination with other switches within the engine system. For instance, it may interact with temperature switches or flow switches to provide a comprehensive monitoring solution. This integration allows for a more holistic approach to system management, where multiple parameters are considered in the decision-making process.

Enhancing System Reliability

By incorporating the 4984879 Pressure Switch into engine systems, reliability is enhanced through proactive monitoring and timely interventions. The switch’s ability to detect and signal pressure anomalies ensures that potential issues are addressed before they escalate into more significant problems. This not only protects the engine but also contributes to the overall efficiency and longevity of the system.

Conclusion

In summary, the 4984879 Pressure Switch plays a significant role in the effective operation of engine systems by providing accurate pressure readings and generating signals that enable timely responses to changing conditions. Its integration with various components, including sensors and other switches, enhances the system’s ability to maintain optimal performance and reliability.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.