This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5334430 Sacrificial Anode by Cummins is a component designed to protect metal parts from corrosion in commercial trucks. Its role is vital in maintaining the integrity and longevity of various truck systems by acting as a sacrificial element that corrodes instead of the protected metal components.

Basic Concepts of Sacrificial Anodes

Sacrificial anodes are metallic components used to protect other metals from corrosion through a process known as cathodic protection. When two dissimilar metals are in electrical contact in the presence of an electrolyte, one metal (the anode) will corrode preferentially, thereby protecting the other metal (the cathode) 1. This mechanism is fundamental in extending the lifespan of metal components exposed to corrosive environments.

Purpose of the 5334430 Sacrificial Anode

The 5334430 Sacrificial Anode is specifically designed to protect critical components within a truck’s cooling system and other systems where corrosion could be a concern. By being more electrochemically active than the components it protects, it ensures that these parts remain intact, thereby maintaining the efficiency and reliability of the truck’s operation.

Key Features

The 5334430 Sacrificial Anode is composed of a magnesium alloy, chosen for its high electrochemical potential relative to other metals commonly used in truck construction. Its design allows for easy installation and replacement, and it is engineered to provide long-lasting protection. Unique attributes include its robust construction and compatibility with a wide range of truck systems, ensuring versatile application.

Benefits of Using the 5334430 Sacrificial Anode

Utilizing the 5334430 Sacrificial Anode offers several advantages. It contributes to the extended lifespan of metal components by preventing corrosion, which in turn reduces the frequency of maintenance and repair needs. This leads to lower overall maintenance costs and improved reliability of the truck, ensuring consistent performance over time.

Installation Guidelines

Proper installation of the 5334430 Sacrificial Anode involves several steps. First, ensure the area where the anode will be installed is clean and free of debris. Use the appropriate tools to secure the anode in place, ensuring it is in electrical contact with the component it is intended to protect. Follow manufacturer guidelines for specific installation details to ensure optimal performance.

Maintenance and Inspection

Regular maintenance and inspection of the 5334430 Sacrificial Anode are recommended to ensure its continued effectiveness. Inspect the anode periodically for signs of wear or significant reduction in size, which may indicate it is time for replacement. Maintaining the anode in good condition is key to ensuring the ongoing protection of the truck’s metal components.

Troubleshooting Common Issues

Common issues with sacrificial anodes may include insufficient protection due to improper installation or environmental factors that accelerate corrosion. Troubleshooting steps involve checking the electrical connection between the anode and the protected component, ensuring the anode is of the correct size and material, and assessing environmental conditions that may affect performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a broad product range and a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive experience and expertise in the field ensure that its products, including the 5334430 Sacrificial Anode, meet the high standards required for commercial applications.

Sacrificial Anode Part 5334430 in Cummins Engines

The Cummins part 5334430, a Sacrificial Anode, is a critical component in the maintenance and longevity of several Cummins engine models. This part is designed to protect the engine’s cooling system by preventing corrosion, which can lead to system failures and reduced engine lifespan.

Application in Specific Engine Models

QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850)

The QSB6.7 M CM2250 and QSC8.3 CM850 (CM2850) engines both benefit from the use of the 5334430 Sacrificial Anode. These engines are commonly used in a variety of applications, including marine, industrial, and agricultural settings. The sacrificial anode ensures that the cooling system remains free from corrosion, which is particularly important in environments where the engines are exposed to saltwater or other corrosive substances.

QSM11 CM570

The QSM11 CM570 engine also utilizes the 5334430 Sacrificial Anode. This engine is known for its durability and reliability, making it a popular choice for heavy-duty applications. The sacrificial anode plays a role in maintaining the integrity of the engine’s cooling system, ensuring that it operates efficiently and reliably over an extended period.

Importance of the Sacrificial Anode

The sacrificial anode is a key component in protecting the engine’s cooling system from corrosion. By sacrificing itself, the anode prevents the engine’s metal components from corroding, thereby extending the life of the engine and reducing maintenance costs. Regular replacement of the sacrificial anode is essential to maintain the engine’s performance and reliability.

Sacrificial Anode Component Usage

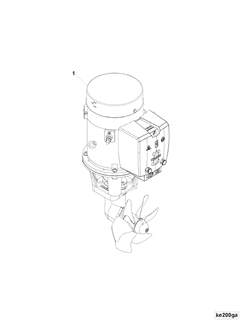

The part 5334430 Sacrificial Anode is a component in marine propulsion systems, specifically designed to protect various engine components from corrosion. Its role is particularly significant in the context of thrusters, which are vital for maneuvering and stabilizing vessels.

Thruster Protection

In thruster systems, the sacrificial anode is installed to safeguard the thruster housing and propeller from the corrosive effects of seawater. As the thruster operates, it is constantly exposed to saltwater, which can lead to galvanic corrosion. The sacrificial anode, made from a more anodic metal, corrodes instead of the thruster components, thereby extending the lifespan of the thruster.

Bow and Stern Thrusters

For bow and stern thrusters, the sacrificial anode is positioned in close proximity to the thruster housing. This strategic placement ensures that the anode is the first to corrode, protecting the more expensive and structurally important components of the thruster. Regular inspection and replacement of the anode are necessary to maintain its effectiveness.

Thruster Drive Systems

In thruster drive systems, the sacrificial anode plays a protective role. It is typically attached to the drive unit, which is often submerged and exposed to corrosive elements. By corroding preferentially, the anode prevents damage to the drive unit’s metal components, ensuring the thruster operates efficiently and reliably over time.

Overall, the integration of part 5334430 Sacrificial Anode in these systems is a proactive measure to combat corrosion, enhancing the durability and performance of marine propulsion components.

Conclusion

The 5334430 Sacrificial Anode by Cummins is a vital component in protecting metal parts from corrosion in commercial trucks and marine propulsion systems. Its application in various engine models and thruster systems demonstrates its versatility and importance in maintaining the integrity and longevity of these systems. Regular maintenance and inspection of this part are crucial to ensure its effectiveness and the continued reliability of the equipment it protects.

-

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.