This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

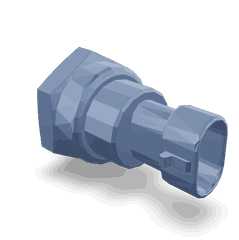

The Cummins 5462276 Pressure Switch is a critical component for commercial truck systems, designed to monitor and regulate pressure within specific systems. This ensures operations remain within safe and efficient parameters, maintaining the performance and reliability of truck systems through accurate pressure readings and timely responses to pressure changes 2.

Basic Concepts of Pressure Switches

A pressure switch operates by opening or closing electrical circuits in response to a certain pressure threshold. It uses a diaphragm or piston that moves with pressure changes, activating or deactivating an electrical contact. These switches are vital in automotive systems for controlling functions like engine lubrication, fuel delivery, and brake systems, ensuring they operate within their designed pressure ranges 1.

Functionality of the 5462276 Pressure Switch

This Cummins part is crucial for the operation of a truck, monitoring and controlling pressure within designated systems. It is used in applications requiring precise pressure management for optimal performance and safety, such as the engine’s lubrication system for maintaining correct oil pressure or in the brake system for adequate brake fluid pressure 2.

Key Features

The 5462276 Pressure Switch is known for its robust design and quality materials, engineered to withstand the harsh environments of commercial truck operations. It may feature adjustable set points for customization to specific application requirements, ensuring durability, accuracy in pressure detection, and reliable operation over an extended service life 2.

Benefits

The advantages of the 5462276 Pressure Switch include enhanced system performance, increased reliability, and improved efficiency. By accurately monitoring and controlling pressure, it helps prevent system failures and extends the lifespan of components, contributing to better fuel economy and reduced maintenance costs 1.

Troubleshooting and Maintenance

Common issues with the 5462276 Pressure Switch include inaccurate pressure readings, failure to activate or deactivate at the correct pressure, and physical damage. Diagnostic steps may involve checking electrical connections, testing the pressure sensing mechanism, and inspecting for wear or damage. Regular maintenance practices, such as cleaning the switch and its connections, and periodic testing of its operation, can help ensure longevity and proper function 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry, committed to innovation, quality, and customer satisfaction 2.

Compatibility of Cummins Pressure Switch 5462276

The Cummins Pressure Switch 5462276 is designed to integrate seamlessly with various Cummins engine models, ensuring optimal performance and reliability across different applications. This pressure switch is engineered to work with the following engines:

Medium-Duty Engines

- 6C8.3: Ensures the engine operates within desired pressure parameters.

- K19: Enhances fuel efficiency and reduces wear.

- K38: Maintains optimal pressure levels for longevity and performance.

Heavy-Duty Engines

- K50: Monitors and regulates pressure for durability and efficiency.

- M11 MECHANICAL: Maintains pressure integrity for smooth operation.

- N14 MECHANICAL: Ensures precise pressure management for enhanced performance.

Industrial and Power Generation Engines

- NH/NT 855: Maintains operational efficiency and safety.

- V28: Ensures consistent pressure levels for performance and longevity.

The Cummins Pressure Switch 5462276 enhances the functionality of these engines by providing precise pressure monitoring and control 2.

Role of Part 5462276 Pressure Switch in Engine Systems

This part is integral to various engine systems, ensuring optimal performance and safety by monitoring and controlling oil pressure within the engine.

Integration with Engine Monitoring Systems

The Pressure Switch continuously assesses oil pressure levels, activating when pressure falls below a predetermined threshold to signal the engine control unit (ECU) for corrective action, preventing potential engine damage due to insufficient lubrication 2.

Coordination with Safety Control Mechanisms

It works with other safety components to ensure the engine operates within safe parameters, triggering a shutdown sequence if oil pressure drops unexpectedly to protect the engine from severe damage 2.

Interaction with Injector and Oil Control Valve

In fuel injection systems, the Pressure Switch ensures consistent oil pressure for the accurate operation of injectors and oil control valves, essential for efficient combustion and overall engine performance 1.

Contribution to Upfit Parts and Performance Enhancements

For engines with performance enhancements, the Pressure Switch ensures adequate oil pressure under increased stress and higher operating temperatures, crucial for longevity and reliability in high-performance engines 2.

Role in Comprehensive System Safety

The Pressure Switch is part of a network that includes various sensors and control units, working together to maintain engine health. Its quick response to changes in oil pressure makes it a key player in this safety network 2.

Conclusion

The Cummins 5462276 Pressure Switch is a multifaceted component that enhances engine performance, ensures safety, and contributes to the efficient operation of various engine systems. Its role in monitoring and controlling oil pressure is indispensable for the sustained health and performance of the engine 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.