This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

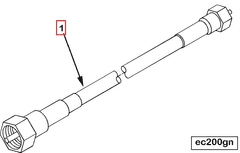

The Cummins 212886 Tachometer Shaft is a component designed for use in commercial trucks, specifically within the tachometer system. Its purpose is to facilitate the accurate measurement and display of engine speed, which is vital for monitoring engine performance and ensuring optimal operation. The significance of this part lies in its contribution to both engine management and driver awareness, allowing for better control and maintenance of the vehicle 1.

Basic Concepts of Tachometer Shafts

A tachometer shaft is a mechanical component that connects the tachometer to the engine. It functions by transferring rotational motion from the engine to the tachometer, enabling the instrument to measure engine speed in revolutions per minute (RPM). This measurement is crucial for various engine management functions, including fuel injection timing and gear shifting in manual transmissions 2.

Purpose of the Cummins 212886 Tachometer Shaft

The Cummins 212886 Tachometer Shaft plays a role in the operation of a truck by ensuring that the tachometer accurately reflects the engine’s RPM. This information is important for engine performance monitoring, as it allows drivers and maintenance personnel to assess the engine’s condition and performance under different loads and speeds. Additionally, it enhances driver awareness by providing real-time feedback on engine speed, which can be used to make informed decisions regarding acceleration, deceleration, and gear changes 3.

Key Features

The Cummins 212886 Tachometer Shaft is characterized by several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operation. The design includes precision-machined components to ensure accurate RPM readings. Additionally, it may feature unique characteristics such as anti-vibration mounts or sealed bearings to improve reliability and reduce maintenance requirements.

Benefits

The advantages provided by the Cummins 212886 Tachometer Shaft include improved accuracy in engine speed readings, which is important for precise engine management. Its durable construction ensures longevity, even in demanding operating conditions. The reliability of this component contributes to the overall efficiency and safety of the vehicle, reducing the likelihood of engine-related issues due to inaccurate RPM readings.

Installation and Compatibility

Proper installation of the Cummins 212886 Tachometer Shaft is important to ensure accurate engine speed readings and reliable operation. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and function within the tachometer system. Installation procedures should follow manufacturer guidelines to maintain the integrity of the component and the accuracy of the tachometer.

Troubleshooting and Maintenance

Common issues with the 212886 Tachometer Shaft may include inaccurate RPM readings or physical damage due to wear and tear. Diagnostic tips for troubleshooting these issues involve checking for proper installation, inspecting for physical damage, and ensuring that all connections are secure. Regular maintenance practices, such as lubrication of moving parts and inspection for wear, can help ensure optimal performance and longevity of the component.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial transportation, demonstrating a commitment to excellence and customer satisfaction.

Role of Part 212886 Tachometer Shaft in Engine Systems

The Tachometer Shaft, identified by part number 212886, is integral to the accurate functioning of engine monitoring systems. This component interfaces directly with the EBM-Instruments, which are essential for displaying engine performance metrics. The Tachometer Shaft transmits rotational speed data from the engine to the tachometer, ensuring that the EBM-Instruments receive precise and real-time information.

In conjunction with the Eng (Engine), the Tachometer Shaft plays a significant role in maintaining the engine’s operational efficiency. By providing continuous feedback on the engine’s RPM (Revolutions Per Minute), it allows for adjustments and diagnostics that can prevent potential issues.

The Tachometer Cable is another component that works in tandem with the Tachometer Shaft. This cable facilitates the transmission of data from the shaft to the tachometer, ensuring that the information displayed is both accurate and timely. The reliability of the Tachometer Cable is paramount, as any disruption in this pathway can lead to incorrect readings, impacting engine performance and diagnostic capabilities.

Together, these components form a cohesive system that enhances engine monitoring and maintenance, allowing for optimal performance and longevity of the engine.

Conclusion

The Cummins 212886 Tachometer Shaft is a vital component in the tachometer system of commercial trucks, ensuring accurate engine speed readings and contributing to engine management and driver awareness. Its durable construction, precise design, and compatibility with specific Cummins engine models make it an essential part for maintaining optimal engine performance and vehicle safety.

-

Duffy, Owen C., and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.