This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

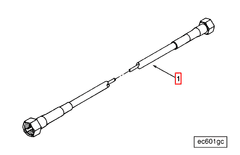

The Tachometer Shaft 212888, a component produced by Cummins, is designed specifically for use in heavy-duty trucks. This shaft facilitates the measurement and display of engine speed within the tachometer system, providing accurate engine performance data to the driver. This information is essential for efficient operation and maintenance of the vehicle 1.

Basic Concepts of Tachometer Shafts

A tachometer shaft is a mechanical component within the tachometer system that transmits rotational motion from the engine to the tachometer. This transmission allows the tachometer to measure the engine’s rotational speed, typically expressed in revolutions per minute (RPM). The tachometer shaft ensures that the tachometer accurately reflects the engine’s operating conditions, aiding in performance monitoring and diagnostics 2.

Purpose of the Tachometer Shaft 212888

The Tachometer Shaft 212888 is integral to the operation of a truck’s tachometer system. It provides a direct mechanical link between the engine and the tachometer, enabling the tachometer to display the engine’s RPM. This offers the driver real-time insights into the engine’s operational status, which is valuable for optimizing driving conditions, ensuring efficient fuel consumption, and preventing engine over-revving 3.

Key Features

The Tachometer Shaft 212888 is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precision engineering to maintain accuracy in RPM measurement. Additionally, the shaft may feature unique elements such as anti-friction bearings or specialized coatings to further improve its performance and longevity.

Benefits of Using Tachometer Shaft 212888

Utilizing the Tachometer Shaft 212888 offers several advantages. Its high-quality construction and precise engineering contribute to improved accuracy in engine speed measurement. The durability of the shaft ensures long-term reliability, reducing the need for frequent replacements. Furthermore, accurate engine speed monitoring can contribute to better fuel efficiency and engine longevity by allowing drivers to operate the engine within optimal RPM ranges.

Installation and Integration

Proper installation of the Tachometer Shaft 212888 is crucial for ensuring its effective operation within the truck’s tachometer system. Installation guidelines recommend careful alignment and secure fastening to prevent misalignment or loosening, which could affect measurement accuracy. Integration considerations may include compatibility with the truck’s existing tachometer system and ensuring that all connections are tight and secure.

Troubleshooting and Maintenance

Common issues with the Tachometer Shaft 212888 may include inaccurate RPM readings or mechanical wear. Troubleshooting steps involve checking for proper installation, ensuring all connections are secure, and inspecting the shaft for signs of wear or damage. Maintenance tips include regular inspection for wear, cleaning to remove any debris, and lubrication of moving parts as necessary. Adhering to these practices can help maintain optimal performance and prolong the component’s lifespan.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of commercial vehicles and industrial applications.

Tachometer Shaft (Part 212888) in Cummins Engines

The Tachometer Shaft, identified by part number 212888, is a critical component in the operation of certain Cummins engines. This part is integral to the engine’s ability to measure and display engine speed, which is essential for monitoring performance and ensuring the engine operates within safe parameters.

Application in K38 Engines

In the K38 engine series, the Tachometer Shaft is designed to interface seamlessly with the engine’s internal mechanisms. It is engineered to provide accurate and reliable readings to the tachometer, ensuring that operators can monitor engine RPM effectively. The precision of this component is crucial for maintaining optimal engine performance and preventing potential damage from over-revving.

Integration with Cummins Engines

Cummins engines, known for their durability and efficiency, incorporate the Tachometer Shaft to enhance operational monitoring. The shaft is typically connected to the engine’s crankshaft or camshaft, depending on the specific engine model. This connection allows it to translate the rotational speed of the engine into a readable format for the tachometer.

The design of the Tachometer Shaft in Cummins engines ensures that it can withstand the harsh operating conditions found in industrial and commercial applications. Its robust construction and precise engineering make it a reliable component for long-term use.

Importance of the Tachometer Shaft

The Tachometer Shaft plays a vital role in the overall functionality of Cummins engines. By providing accurate RPM readings, it helps in:

- Monitoring engine performance

- Preventing engine damage

- Ensuring efficient operation

- Facilitating maintenance and troubleshooting

The integration of the Tachometer Shaft in Cummins engines underscores the brand’s commitment to quality and reliability, ensuring that operators have the necessary tools to maintain and optimize engine performance.

Role of Part 212888 Tachometer Shaft in Engine Systems

The Tachometer Shaft, identified by part number 212888, is an essential component in the integration of tachometers within engine systems. Its primary function is to transmit rotational speed data from the engine’s drive mechanism to the tachometer. This data transmission is fundamental for accurate engine performance monitoring.

Integration with the Drive Mechanism

The Tachometer Shaft interfaces directly with the engine’s drive mechanism, which typically includes components such as the crankshaft or camshaft. As these components rotate, the Tachometer Shaft captures their rotational speed. This interaction ensures that the tachometer receives real-time data, allowing for precise monitoring of engine RPM (revolutions per minute).

Connection to the Tachometer

Once the rotational speed is captured by the Tachometer Shaft, it is transmitted to the tachometer. The tachometer then converts this data into a readable format, typically displayed as RPM on the instrument cluster. This allows engineers and mechanics to monitor engine performance, diagnose potential issues, and ensure optimal operation.

Importance in Engine Systems

The accurate transmission of rotational speed data is vital for various engine management functions. It aids in the calibration of fuel injection systems, ignition timing, and other performance-related parameters. Additionally, it provides valuable insights during diagnostic procedures, helping identify irregularities in engine operation.

Conclusion

The Tachometer Shaft 212888 by Cummins is a critical component in the tachometer system of heavy-duty trucks. Its role in accurately measuring and displaying engine speed is essential for efficient operation, maintenance, and performance monitoring of the vehicle. The high-quality construction, precise engineering, and durability of this part ensure long-term reliability and optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.