This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4071443 Tappet Roller Pin is a component designed for use in heavy-duty truck engines. Manufactured by Cummins, a well-regarded name in the automotive industry, this tappet roller pin is integral to the efficient operation of truck engines. Its design and functionality contribute to the overall performance and reliability of the engine.

Basic Concepts of Tappet Roller Pins

Tappet roller pins, also known as rocker arm roller pins or tappet rollers, are components found in the valve train of an engine. Their primary function is to facilitate the transfer of motion from the camshaft to the valves, ensuring precise and efficient valve operation. Tappet roller pins interact with other engine components such as the camshaft, rocker arms, and valves, playing a role in the engine’s operation by reducing friction and wear on these parts 1.

Role of the 4071443 Tappet Roller Pin in Truck Engines

The 4071443 Tappet Roller Pin is specifically engineered to enhance the operation of heavy-duty truck engines. It interacts with the valve train, transferring motion from the camshaft to the valves with minimal friction. This interaction is vital for maintaining the engine’s performance, ensuring that valves open and close at the correct times and with the appropriate force. The efficient operation of the tappet roller pin contributes to the engine’s overall efficiency and durability.

Key Features of the 4071443 Tappet Roller Pin

The 4071443 Tappet Roller Pin boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. Its design includes precision-machined surfaces and a robust construction, which contribute to its reliability under the demanding conditions of heavy-duty truck engines. Additionally, the tappet roller pin may feature unique attributes such as enhanced lubrication channels or specialized coatings to further improve its performance.

Benefits of Using the 4071443 Tappet Roller Pin

Utilizing the 4071443 Tappet Roller Pin in heavy-duty truck engines offers several benefits. It contributes to improved engine efficiency by ensuring smooth and precise valve operation. The reduction in friction and wear on engine components leads to enhanced durability and longevity of the engine. Furthermore, the tappet roller pin’s design and material composition support overall engine performance, making it a valuable component for maintaining the reliability and efficiency of heavy-duty trucks.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the 4071443 Tappet Roller Pin, regular maintenance and troubleshooting are recommended. Common issues may include wear or damage to the pin, which can affect valve operation and engine performance. Symptoms of failure may include unusual engine noises, decreased performance, or increased oil consumption. Diagnostic procedures should involve a thorough inspection of the tappet roller pin and related components. Recommended maintenance practices include regular lubrication, inspection for wear, and replacement as necessary to prevent engine damage and ensure continued efficient operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality engine components and systems. The company’s commitment to innovation, quality, and customer satisfaction is evident in its wide range of products, including the 4071443 Tappet Roller Pin. Cummins’ dedication to excellence ensures that its components meet the demanding requirements of heavy-duty applications, contributing to the reliability and performance of engines worldwide 2.

Role of Part 4071443 Tappet Roller Pin in Engine Systems

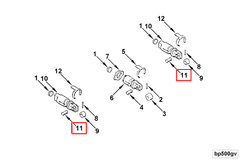

The part 4071443 Tappet Roller Pin is an integral component in the operation of various engine systems, particularly in the valve train mechanism. This pin is designed to facilitate smooth and efficient movement between the camshaft and the valve, ensuring optimal engine performance.

Interaction with the Valve Tappet

The Tappet Roller Pin interfaces directly with the valve tappet, also known as a lifter. The tappet’s primary function is to transfer motion from the camshaft to the valve. The roller pin, with its smooth surface, reduces friction and wear on the tappet, allowing for more precise and consistent valve operation.

Contribution to the Rocker Mechanism

In overhead valve (OHV) engines, the Tappet Roller Pin plays a significant role in the rocker mechanism. The pin is often part of a rocker arm assembly, where it helps to amplify the motion from the tappet to the valve. This amplification ensures that the valve opens and closes with the correct timing and force, which is essential for efficient combustion.

Enhancing Lever Functionality

The lever, or rocker arm, relies on the Tappet Roller Pin to maintain its operational integrity. The pin’s design allows the lever to pivot smoothly, transferring the camshaft’s rotational motion into the linear motion required to open and close the valve. This smooth transfer is vital for maintaining engine efficiency and longevity.

Supporting the Base and Overall System

The base of the engine, which houses the valve train components, benefits from the presence of the Tappet Roller Pin. By ensuring that the tappet, lever, and rocker arm operate with minimal friction, the pin contributes to the stability and reliability of the entire valve train system. This, in turn, supports the base by reducing the stress and wear on other components.

Conclusion

In summary, the part 4071443 Tappet Roller Pin is a key element in the intricate dance of engine components, ensuring that each part—from the tappet to the valve—functions harmoniously to deliver peak engine performance. Its role in reducing friction, enhancing durability, and supporting the efficient operation of the valve train system underscores its importance in the maintenance and performance of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.