3068859

Tappet Top Stop Cap

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tappet Top Stop Cap, identified by part number 3068859, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the engine system, contributing to the overall functionality and reliability of truck engines. Cummins is renowned for its high-quality engine components, and the Tappet Top Stop Cap is no exception, designed to meet the rigorous demands of heavy-duty applications 1.

Function and Operation

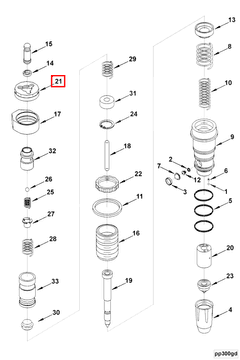

The Tappet Top Stop Cap operates within the valve train system of an engine. It is positioned at the top of the tappet, serving as a protective cover and a stop mechanism. Its primary role is to prevent the tappet from moving beyond its designated range, ensuring precise valve operation. The cap interacts with the tappet and other valve train components, such as the camshaft and rocker arms, to maintain consistent valve timing and clearance. This interaction is crucial for the efficient operation of the engine, as it ensures that the valves open and close at the correct intervals, which is vital for engine performance 2.

Purpose of the Tappet Top Stop Cap

The Tappet Top Stop Cap plays a significant role in the operation of a truck engine. By limiting the travel of the tappet, it helps maintain the correct valve clearance, which is essential for optimal engine performance. Proper valve clearance ensures that the valves open sufficiently to allow the necessary airflow into and out of the combustion chamber, contributing to efficient combustion and power output. Additionally, the cap protects the tappet from debris and contaminants, enhancing the durability and reliability of the engine 3.

Key Features

The Tappet Top Stop Cap is designed with several key features that enhance its functionality and durability. It is typically made from high-strength materials, such as steel or hardened alloys, to withstand the high pressures and temperatures within the engine. The cap is precision-machined to ensure a perfect fit and smooth operation. Additionally, it may feature a sealing mechanism to prevent oil leakage, which is important for maintaining proper lubrication within the valve train.

Benefits

The Tappet Top Stop Cap offers several advantages that contribute to improved engine efficiency and durability. By ensuring precise valve operation, it helps maintain optimal engine performance and fuel efficiency. The durable construction of the cap enhances the longevity of the valve train components, reducing the need for frequent replacements. Additionally, the cap’s design may simplify maintenance procedures, making it easier to inspect and service the valve train.

Installation Process

Installing the Tappet Top Stop Cap requires careful attention to detail to ensure proper function and durability. The process involves the following steps:

- Ensure the engine is clean and free of debris.

- Position the tappet within the valve train assembly.

- Place the Tappet Top Stop Cap over the tappet, ensuring it is aligned correctly.

- Secure the cap in place, following the manufacturer’s guidelines for torque specifications.

- Verify that the cap is properly seated and that the tappet operates within the designated range.

Common Issues and Troubleshooting

Typical problems associated with the Tappet Top Stop Cap may include wear, damage, or improper installation. Symptoms of issues may include noisy valve train operation, inconsistent engine performance, or oil leaks. To troubleshoot these problems, inspect the cap for signs of wear or damage, ensure it is properly installed, and check for any oil leaks around the cap. If necessary, replace the cap with a new one to restore proper function.

Maintenance Tips

To ensure the longevity and optimal performance of the Tappet Top Stop Cap, regular maintenance is recommended. This includes:

- Inspecting the cap during routine engine maintenance for signs of wear or damage.

- Ensuring proper lubrication within the valve train to reduce friction and wear.

- Following the manufacturer’s guidelines for torque specifications during installation to prevent over-tightening or under-tightening.

- Keeping the engine clean to prevent debris from affecting the cap’s operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. Founded in 1919, Cummins has a long-standing reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency. Cummins is committed to providing customers with the highest quality products and services, backed by comprehensive support and warranty programs 4.

Compatibility with Cummins Engines

The Tappet Top Stop Cap, identified by the part number 3068859, is compatible with various Cummins engines, ensuring the proper functioning of the tappet mechanism, which is essential for the engine’s overall performance and longevity.

Compatible Engines

- 6B5.9: Ensures smooth and efficient tappet mechanism operation.

- K19, K38, K50: Maintains correct clearance and reduces wear on tappet components.

- M11 CELECT PLUS, M11 MECHANICAL: Enhances valve train reliability and performance.

- N14 MECHANICAL: Ensures correct tappet mechanism function, contributing to engine durability.

- NH/NT 855: Maintains proper tappet clearance and prevents excessive wear.

- QSK19 CM500, V903, VTA903 CM2250 V105: Ensures tappet mechanism operates within specified parameters, enhancing engine efficiency and lifespan.

Integration with Engine Components

The Tappet Top Stop Cap (Part 3068859) is an essential component in the intricate assembly of various engine systems. Its primary function is to ensure the proper operation and alignment of the tappets within the engine. Here’s how it integrates with the provided components:

Engine Components

- Cam Follower Housing: Maintains precise positioning of the tappets, ensuring smooth interaction between the camshaft and the valve train.

- Connecting Rod and Piston: Supports the reliable operation of the connecting rod and piston assembly by ensuring tappets are correctly positioned.

- Rocker Housing: Ensures tappets, which interact with the rockers, are correctly aligned, crucial for accurate transmission of camshaft motion to the valves.

- Injectors and EBM-Injector: Maintains the integrity of the valve train, ensuring injectors operate within designed parameters, contributing to fuel efficiency and performance.

- Oil Manifold and Oil Control Valve Mounting Plumbing: Supports efficient functioning of the oil manifold and oil control valve plumbing by maintaining tappet alignment.

- Aftercooler and Aftercooler Plumbing: Influences overall engine performance, including the efficiency of the aftercooler system, by ensuring smooth valve train operation.

- Tachometer Parts Kit: Ensures reliable engine RPM readings by supporting accurate tappet operation.

Supporting Components

- Hardware Kit and Engine Installation Kit: Includes the Tappet Top Stop Cap for correct assembly and installation of the engine, promoting reliability and performance.

- Cover and Oil Pan: Supports the integrity of the engine cover and oil pan by maintaining tappet alignment, preventing undue stress on these components.

- On-Board Spares and Kit Spares: Sometimes included in on-board spares kits, highlighting its importance in maintaining engine function during operations where downtime must be minimized.

Conclusion

The Tappet Top Stop Cap (Part 3068859) is a key component in ensuring the precise operation of the valve train, which in turn supports the efficient functioning of various engine systems. Its role extends beyond simple alignment, impacting overall engine performance, reliability, and diagnostic accuracy.

-

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4358495, ISL8.9 CM2880 L112.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.