4062313

Pressure Temperature Sensor

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

Pressure temperature sensors are crucial for the optimal operation of commercial trucks, ensuring engine performance and longevity. Among these, the Cummins 4062313 Pressure Temperature Sensor is renowned for its precision and reliability. This article provides a comprehensive overview of this sensor, detailing its function, integration, and maintenance.

Basic Concepts Related to Pressure Temperature Sensors

A pressure temperature sensor is essential for monitoring and regulating engine temperature and pressure. It consists of a sensing element, a signal conditioning circuit, and a housing. The sensor converts physical parameters—pressure and temperature—into electrical signals, which are transmitted to the engine control unit (ECU) for interpretation and adjustment of engine operations 1.

Purpose of the Cummins 4062313 Pressure Temperature Sensor

The Cummins 4062313 Pressure Temperature Sensor is vital for engine operation. It provides real-time data on engine temperature and pressure to the ECU, enabling precise adjustments that ensure optimal engine efficiency and performance. This sensor helps prevent overheating and pressure-related failures, contributing to enhanced fuel efficiency and reduced emissions 2.

How the Cummins 4062313 Pressure Temperature Sensor Works

The Cummins 4062313 Pressure Temperature Sensor uses advanced sensing mechanisms, such as piezoelectric or resistive elements, to detect changes in pressure and temperature. These changes are converted into electrical signals and transmitted to the ECU. The ECU processes this data to adjust fuel injection, turbocharger operation, and cooling systems, ensuring the engine operates within optimal parameters 3.

Troubleshooting the Cummins 4062313 Pressure Temperature Sensor

Common issues with this Cummins part include inaccurate readings, engine performance problems, and warning lights. Troubleshooting involves a visual inspection for damage or corrosion, followed by detailed checks using diagnostic tools. If a faulty sensor is identified, it should be replaced and properly calibrated to maintain accuracy.

Maintenance of the Cummins 4062313 Pressure Temperature Sensor

Regular maintenance is essential for the longevity of this sensor. Cleaning and inspecting the sensor regularly can prevent buildup and corrosion. Check for any physical damage that could affect performance. Avoid exposing the sensor to extreme temperature and pressure conditions, and handle it carefully during engine maintenance to prevent accidental damage.

Cummins: A Leader in Engine Technology

Cummins is renowned for its commitment to innovation and quality in engine technology. With a strong market presence, Cummins leads the industry in research and development, particularly in sensor technology. Their dedication to quality assurance ensures that components like the 4062313 Pressure Temperature Sensor meet the highest standards.

Expert Insights and Best Practices

Industry experts emphasize the importance of pressure temperature sensors in maintaining engine efficiency and reliability. Best practices include regular inspections, proper calibration, and staying updated with the latest technological advancements. Real-world examples and case studies highlight the sensor’s performance and reliability, underscoring its critical role in engine management.

Compatibility with Cummins Engines

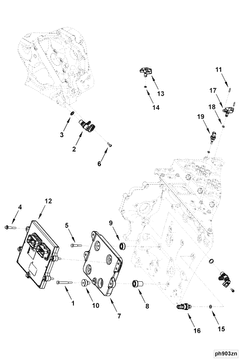

The Pressure Temperature Sensor part number 4062313 is designed to fit seamlessly into various Cummins engine models, including the ISB CM2150, ISB6.7 CM2250, ISB CM850, and QSB5.9 CM850. These engines benefit from the precise monitoring capabilities of this sensor, ensuring efficient operation and longevity.

Role of the 4062313 Pressure Temperature Sensor in Engine Systems

The 4062313 Pressure Temperature Sensor is integral to modern engine systems, particularly in conjunction with the Engine Control Module (ECM). It provides real-time data on pressure and temperature conditions, enabling the ECM to make precise adjustments to fuel injection, ignition timing, and other critical parameters.

Interaction with the Engine Control Module (ECM)

The ECM relies on accurate data from the Pressure Temperature Sensor to optimize engine performance. The sensor continuously monitors pressure and temperature within the intake manifold and other relevant areas, transmitting this data to the ECM for informed decisions about fuel delivery and ignition timing.

Enhancing Fuel Efficiency and Emissions Control

By providing precise pressure and temperature readings, the Pressure Temperature Sensor enables the ECM to fine-tune the air-fuel ratio, essential for achieving maximum fuel efficiency while minimizing harmful emissions. The sensor’s data allows the ECM to adapt to varying driving conditions, ensuring optimal engine performance.

Supporting Diagnostic and Maintenance Functions

The Pressure Temperature Sensor plays a role in the engine’s diagnostic systems. The ECM uses the sensor’s data to monitor the health and performance of various engine components. Any anomalies in the pressure or temperature readings can trigger diagnostic trouble codes (DTCs), alerting mechanics to potential issues that need attention.

Integration with Other Engine Systems

Beyond its primary interaction with the ECM, the Pressure Temperature Sensor contributes to the overall harmony of the engine system. It works in tandem with other sensors and actuators to create a cohesive feedback loop that enhances engine responsiveness and durability.

Conclusion

The Cummins 4062313 Pressure Temperature Sensor is a vital component in the operation of commercial truck engines. Its ability to monitor and regulate temperature and pressure ensures optimal engine performance, efficiency, and longevity. Regular maintenance and proper troubleshooting are essential to maximize its benefits. Cummins’ commitment to quality and innovation further reinforces the sensor’s reliability and effectiveness in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.