This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

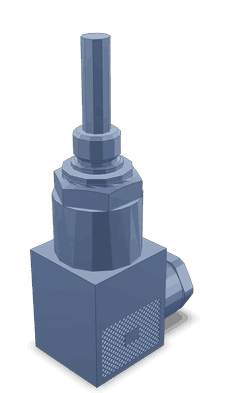

The Cummins 4099166 Temperature Sensor is designed to monitor the temperature within a truck’s engine system, providing accurate readings to maintain optimal operating conditions. This sensor ensures the engine operates efficiently and reliably, contributing to overall vehicle performance and longevity.

Basic Concepts of Temperature Sensors

Temperature sensors measure the temperature of their surroundings and convert this measurement into an electrical signal. They are used in automotive systems to monitor various components, such as the engine, transmission, and exhaust, helping maintain optimal operating temperature for efficiency, performance, and longevity 1.

Role of the 4099166 Temperature Sensor in Truck Operation

The Cummins 4099166 Temperature Sensor monitors the temperature within the engine system of commercial trucks. It provides real-time temperature data to the engine control unit (ECU), allowing for precise adjustments to fuel injection, ignition timing, and other parameters. This ensures the engine operates within its optimal temperature range, enhancing performance and reducing the risk of overheating or other temperature-related issues 2.

Key Features of the 4099166 Temperature Sensor

The Cummins 4099166 Temperature Sensor is distinguished by its high-quality materials, ensuring durability and accuracy in various operating conditions. Technological advancements include improved sensitivity and faster response times, contributing to more accurate temperature readings and better overall engine management 3.

Benefits of Using the 4099166 Temperature Sensor

Incorporating the Cummins 4099166 Temperature Sensor into truck systems offers several advantages. It contributes to improved engine performance by ensuring the engine operates within its optimal temperature range, leading to enhanced fuel efficiency. Additionally, maintaining optimal operating temperatures can prolong the lifespan of engine components, reducing the need for frequent repairs or replacements.

Installation and Integration

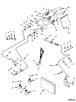

Proper installation of the Cummins 4099166 Temperature Sensor is vital for its effective operation. It should be installed in a location that allows it to accurately measure the engine temperature, typically near the thermostat housing or within the engine block. Ensuring all connections are secure and the sensor is properly aligned is important. Following the manufacturer’s guidelines will help avoid potential issues and ensure the sensor functions correctly within the engine system.

Troubleshooting Common Issues

Common problems associated with temperature sensors include inaccurate readings, sensor failure, and electrical issues. To troubleshoot these problems, begin by checking the sensor’s connections to ensure they are secure and free from corrosion. If the sensor is providing inaccurate readings, it may need to be calibrated or replaced. Electrical issues can often be traced to faulty wiring or a poor connection, which can be resolved by inspecting and repairing the wiring as necessary.

Maintenance Tips

Routine maintenance of the Cummins 4099166 Temperature Sensor is important to ensure its optimal functioning. This includes periodic inspections to check for signs of wear or damage, ensuring that connections remain secure, and performing calibration checks as recommended by the manufacturer. Additionally, following the recommended replacement schedule can help prevent sensor failure and ensure accurate temperature readings over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation within the commercial truck industry for producing reliable and high-performance products. Their extensive product portfolio includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Role of Part 4099166 Temperature Sensor in Engine Systems

The Cummins 4099166 Temperature Sensor is integral to the operational integrity of the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines. This component monitors the engine’s temperature, ensuring it remains within optimal operating conditions. By providing real-time temperature data, the sensor plays a role in preventing overheating, which can lead to engine damage or failure.

In the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines, the temperature sensor is strategically placed to capture accurate readings from the engine’s critical areas. This placement allows for precise monitoring and timely alerts, enabling operators to take corrective actions if necessary. The sensor’s compatibility with these engines ensures seamless integration and reliable performance, contributing to the overall efficiency and longevity of the engines.

The part 4099166 is engineered to withstand the demanding conditions within these engines, including high temperatures and pressures. Its robust design ensures durability and consistent performance, making it a vital component for maintaining engine health. The sensor’s compatibility with both the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines highlights its versatility and importance in the engine’s ecosystem.

Integration with the Engine Instrument System

The temperature sensor provides real-time data on the engine’s temperature, which is essential for the engine instrument system. This system relies on precise temperature readings to display accurate information to the operator. The sensor’s data helps in monitoring the engine’s thermal state, allowing for timely adjustments and interventions if temperatures exceed safe limits.

Contribution to the Engine Monitoring System

In the engine monitoring system, the temperature sensor plays a role by continuously feeding temperature data into the system. This data is used for comprehensive engine health assessments, facilitating predictive maintenance and early detection of potential issues. The sensor ensures that the monitoring system has up-to-date information on the engine’s thermal conditions, which is vital for maintaining efficiency and preventing overheating.

Interaction with the Panel

The panel, which often serves as the primary interface for engine operators, benefits greatly from the temperature sensor’s input. By providing accurate temperature readings, the sensor enables the panel to display current engine temperatures, allowing operators to make informed decisions quickly. This real-time data is essential for maintaining safe operating conditions and ensuring that the engine operates within its specified temperature range.

Overall System Enhancement

Overall, the Cummins 4099166 Temperature Sensor enhances the functionality of engine systems by ensuring that temperature-related data is consistently accurate and reliable. Its integration with the engine instrument system, engine monitoring system, and panel creates a cohesive network that promotes efficient engine operation, enhances safety, and supports proactive maintenance practices.

Conclusion

The Cummins 4099166 Temperature Sensor is a critical component in maintaining the optimal performance and longevity of commercial truck engines. Its accurate temperature readings enable precise engine management, contributing to enhanced fuel efficiency, reduced risk of overheating, and prolonged engine component lifespan. Proper installation, routine maintenance, and timely troubleshooting are essential to ensure the sensor’s effective operation and the overall health of the engine system.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Haoran Hu, Simon J Baseley, and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Douglas R. Fehan, Design of Racing and High-Performance Engines 2004-2013, SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.