Introduction

The Cummins 4307262 Temperature Sensor is a specialized component designed for use in commercial trucks. Its purpose is to monitor the temperature within the engine system, providing vital data that contributes to the overall efficiency and safety of the vehicle. This sensor is integral to maintaining optimal operating conditions, ensuring that the engine performs reliably under various driving conditions 1.

Basic Concepts of Temperature Sensors

A temperature sensor is a device that measures the temperature of its surroundings and converts this measurement into an electrical signal. In automotive systems, these sensors are used to monitor various components, such as the engine, transmission, and exhaust. They play a role in ensuring that these systems operate within safe temperature ranges, thereby preventing overheating and potential damage 2.

Role of the 4307262 Temperature Sensor in Truck Operation

The Cummins 4307262 Temperature Sensor specifically monitors the temperature of the engine coolant. By providing real-time data to the engine management system, it allows for precise control of the engine’s operating temperature. This sensor helps in adjusting the fuel injection timing and the operation of the cooling system, which are critical for maintaining engine efficiency and preventing overheating 3.

Key Features of the 4307262 Temperature Sensor

The Cummins 4307262 Temperature Sensor is designed with several features that enhance its performance and reliability. It is constructed using high-quality materials that can withstand the harsh conditions within a truck’s engine compartment. The sensor incorporates advanced technology to ensure accurate temperature readings, which are essential for the proper functioning of the engine management system.

Benefits of Using the 4307262 Temperature Sensor

Incorporating the Cummins 4307262 Temperature Sensor into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the engine operates at optimal temperatures. This can lead to better fuel economy and reduced emissions. Additionally, the sensor enhances safety by preventing overheating, which can cause engine damage. It also helps in prolonging the lifespan of engine components by maintaining consistent operating conditions.

Installation and Integration

Installing the Cummins 4307262 Temperature Sensor involves placing it in the engine coolant passage and connecting it to the engine management system. This process may require specific wiring configurations to ensure that the sensor communicates effectively with the vehicle’s computer. Proper installation is vital for the sensor to function correctly and provide accurate temperature readings.

Troubleshooting Common Issues

Typical problems with the Cummins 4307262 Temperature Sensor may include inaccurate temperature readings or complete sensor failure. Diagnostic procedures involve checking the sensor’s wiring for damage, ensuring proper installation, and verifying that the sensor is compatible with the engine management system. Solutions may range from recalibrating the sensor to replacing it if it is found to be faulty.

Maintenance Tips

To ensure the continued accurate performance of the Cummins 4307262 Temperature Sensor, regular maintenance is recommended. This includes checking the sensor for any signs of damage or corrosion and ensuring that its connections are secure. Periodic calibration may also be necessary to maintain the accuracy of the temperature readings.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is committed to innovation and sustainability in the automotive industry. The company offers a diverse product range, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Compatibility with Cummins Engines

The Temperature Sensor part 4307262, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. Specifically, this sensor is compatible with the B4.5 CM2350 B129B and B6.7 CM2350 B135B engines. These engines are part of Cummins’ lineup that includes models such as the B4.5 CM2350 B104 and F3.8 CM2350 F120B.

The sensor’s design ensures it fits precisely within the engine’s architecture, providing accurate temperature readings critical for engine performance and safety. This compatibility extends across these models, allowing for a standardized approach to maintenance and repair.

For the B4.5 CM2350 B129B and B6.7 CM2350 B135B engines, the sensor’s placement is strategically chosen to monitor the engine’s temperature effectively. This ensures that the engine operates within optimal temperature ranges, preventing overheating and potential damage.

Similarly, the F3.8 CM2350 F120B engine also benefits from this sensor, as it is engineered to fit into the engine’s design, providing reliable temperature data. This consistency in design allows for ease of replacement and maintenance across different engine models, enhancing the overall reliability and efficiency of the engines.

Role of Part 4307262 Temperature Sensor in Engine Systems

The 4307262 Temperature Sensor is integral to the precise monitoring and regulation of temperature within various engine systems. Its application spans across multiple components, ensuring optimal performance and efficiency.

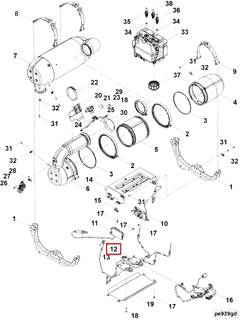

Aftertreatment Arrangement

In the aftertreatment arrangement, the 4307262 Temperature Sensor is positioned to monitor the temperature of exhaust gases. This data is vital for the effective operation of the aftertreatment system, as it allows for the fine-tuning of processes such as selective catalytic reduction (SCR) and diesel particulate filter (DPF) regeneration. Accurate temperature readings ensure that these processes occur within their optimal temperature ranges, enhancing emissions control and maintaining system longevity.

Aftertreatment Device

Within the aftertreatment device, the 4307262 Temperature Sensor plays a significant role in maintaining the device’s efficiency. By providing real-time temperature data, the sensor enables the engine control unit (ECU) to adjust the operation of the aftertreatment device dynamically. This ensures that the device operates within safe temperature limits, preventing damage and ensuring consistent performance.

Aftertreatment System

The aftertreatment system relies on the 4307262 Temperature Sensor to maintain overall system integrity. The sensor’s accurate temperature readings are used to optimize the timing and duration of regeneration cycles, ensuring that the system operates efficiently while minimizing the risk of overheating or underperformance. This contributes to the system’s ability to meet stringent emissions standards.

Module Bracket

The module bracket serves as a mounting point for various sensors and modules within the engine system. The 4307262 Temperature Sensor, when installed on this bracket, provides critical temperature data to the ECU. This information is used to make adjustments to the engine’s operation, ensuring that all components within the module bracket—such as the ECU itself and other sensors—function within their specified temperature ranges.

Sensor Bracket

The sensor bracket is specifically designed to house and secure various sensors, including the 4307262 Temperature Sensor. This bracket ensures that the sensor is positioned correctly within the engine system, allowing it to accurately measure temperatures at key points. The data collected is essential for the ECU to make informed decisions regarding fuel injection, ignition timing, and other critical engine parameters.

Conclusion

Overall, the 4307262 Temperature Sensor is a vital component in maintaining the efficiency and reliability of engine systems. Its precise temperature measurements enable the ECU to make real-time adjustments, ensuring that all interconnected components operate within their optimal temperature ranges.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.