This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4307480 Temperature Sensor is a specialized component designed for use in commercial trucks. Its purpose is to monitor the temperature within the engine system, providing vital data that helps maintain optimal operating conditions. This sensor plays a role in ensuring the engine operates efficiently and reliably, contributing to the overall performance and longevity of the vehicle 1.

Basic Concepts of Temperature Sensors

Temperature sensors are devices that measure the temperature of their surroundings and convert this measurement into an electrical signal. They operate based on various principles, including thermocouples, thermistors, and resistance temperature detectors (RTDs). In automotive systems, temperature sensors are used to monitor engine temperature, coolant temperature, and other critical parameters to ensure the vehicle operates within safe limits. These sensors provide data that helps regulate engine performance, prevent overheating, and maintain efficient operation 2.

Role of the 4307480 Temperature Sensor in Truck Operation

The Cummins 4307480 Temperature Sensor is specifically designed to monitor the temperature within a truck’s engine system. By providing accurate temperature readings, this sensor helps the engine control unit (ECU) make informed decisions about fuel injection, ignition timing, and other critical parameters. This ensures the engine operates within optimal temperature ranges, enhancing efficiency, reducing emissions, and preventing damage from overheating. The sensor’s role in maintaining these conditions is vital for the reliable and efficient operation of commercial trucks 3.

Key Features of the 4307480 Temperature Sensor

The Cummins 4307480 Temperature Sensor is engineered with several key features that enhance its performance and reliability. Its design incorporates high-quality materials that withstand the harsh conditions within an engine environment. The sensor utilizes advanced technology to provide accurate and consistent temperature readings. Additionally, its robust construction ensures durability and longevity, making it a reliable component for commercial truck applications 4.

Benefits of Using the 4307480 Temperature Sensor

Using the Cummins 4307480 Temperature Sensor offers several advantages. It contributes to improved engine efficiency by ensuring the engine operates within optimal temperature ranges. This can lead to better fuel economy and reduced emissions. The sensor’s durable construction and reliable performance enhance the overall durability of the engine system. Additionally, accurate temperature monitoring helps prevent overheating and related damage, contributing to the longevity and performance of the vehicle 5.

Installation and Integration

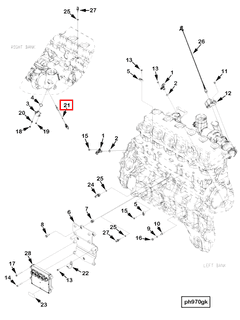

Proper installation and integration of the Cummins 4307480 Temperature Sensor are important for its effective operation. The sensor should be installed in a location that provides an accurate reading of the engine temperature, typically near the thermostat or within the engine block. It is important to follow the manufacturer’s guidelines for installation to ensure proper fit and function. Additionally, any necessary electrical connections should be securely made to prevent issues with signal transmission 6.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important to ensure the continued accurate performance of the Cummins 4307480 Temperature Sensor. Common issues may include inaccurate readings, which can be caused by sensor fouling, electrical connection problems, or sensor failure. Regular inspection and cleaning of the sensor can help prevent fouling. Ensuring all electrical connections are secure and free from corrosion can also help maintain accurate readings. If the sensor fails, it should be replaced according to the manufacturer’s recommendations to ensure continued accurate temperature monitoring 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and customer satisfaction in the automotive and commercial truck industries. The company offers a wide range of products, including engines, powertrain components, and aftermarket parts, designed to meet the demanding requirements of commercial applications. Cummins’ commitment to innovation and excellence has made it a trusted name in the industry 8.

Temperature Sensor 4307480 in Cummins Engines

The Temperature Sensor 4307480, manufactured by Cummins, is a component in the ISL G CM2180 and ISX12 G CM2180 EJ engines. This sensor plays a role in monitoring the engine’s temperature, ensuring optimal performance and preventing potential overheating issues.

In the ISL G CM2180 engine, the temperature sensor is strategically positioned to provide real-time data to the engine control unit (ECU). This data is essential for maintaining the engine’s efficiency and longevity. Similarly, in the ISX12 G CM2180 EJ engine, the sensor’s placement is designed to capture accurate temperature readings, which are vital for the ECU to make necessary adjustments to the engine’s operation.

Both engines rely on the precise functionality of the temperature sensor to manage various parameters, including fuel injection timing and cooling system operations. The sensor’s role in these engines underscores its importance in the overall engine management system 9.

Role of Part 4307480 Temperature Sensor in Engine Systems

The part 4307480 temperature sensor is a component in the effective operation of several engine systems. Its primary function is to monitor and relay temperature data to the Engine Control Module (ECM). This data is vital for the ECM to make informed decisions regarding fuel injection timing, ignition timing, and other parameters that ensure optimal engine performance.

Interaction with the Engine Control Module (ECM)

The temperature sensor continuously sends temperature readings to the ECM. The ECM uses this data to adjust various engine parameters. For instance, during cold starts, the ECM may enrich the fuel mixture based on the temperature sensor’s input to ensure smooth engine operation. As the engine warms up, the ECM will lean out the mixture for better fuel efficiency, all guided by the temperature sensor’s accurate readings 10.

Turbocharger Management

In turbocharged engines, the temperature sensor plays a role in managing the turbocharger’s operation. The ECM uses temperature data to control the wastegate, which regulates the turbocharger’s boost pressure. Higher temperatures can indicate increased engine load or potential overheating, prompting the ECM to adjust the wastegate to maintain safe operating conditions. This ensures that the turbocharger operates within its optimal range, enhancing both performance and durability 11.

By providing real-time temperature data, the part 4307480 temperature sensor enables the ECM to make precise adjustments, resulting in improved engine efficiency, reduced emissions, and enhanced overall performance.

Conclusion

The Cummins 4307480 Temperature Sensor is a vital component in the operation of commercial truck engines. Its accurate temperature readings enable the engine control unit to make informed decisions about fuel injection, ignition timing, and other critical parameters. This ensures the engine operates within optimal temperature ranges, enhancing efficiency, reducing emissions, and preventing damage from overheating. The sensor’s durable construction and reliable performance contribute to the overall durability and longevity of the engine system. Proper installation, regular maintenance, and troubleshooting are essential to ensure the continued accurate performance of this Cummins part.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩ -

Cummins Inc. (n.d.). About Cummins. Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5613077). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.