This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

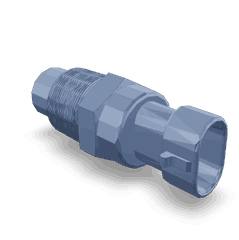

The Cummins 4327022 Temperature Switch is a component designed to monitor and regulate engine temperature in commercial trucks. Its purpose is to ensure the engine operates within safe temperature limits, contributing to the overall efficiency and longevity of the vehicle. Understanding its function and significance is vital for maintaining optimal truck performance.

Basic Concepts of Temperature Switches

A temperature switch is a device that opens or closes an electrical circuit in response to temperature changes. It functions by utilizing a temperature-sensitive element that expands or contracts with temperature variations, thereby activating or deactivating the switch. In automotive systems, temperature switches are commonly used to control various functions such as engine cooling fans, warning lights, and other temperature-sensitive operations 1.

Purpose of the Cummins 4327022 Temperature Switch

The Cummins 4327022 Temperature Switch plays a role in the engine cooling system by monitoring the engine’s temperature and activating the cooling fan when necessary. This helps maintain the engine within its optimal operating temperature range. Additionally, it may be used in other applications within the truck’s system to regulate temperature-sensitive components.

Key Features

The Cummins 4327022 Temperature Switch is characterized by its robust design and high-quality materials, which ensure durability and reliable performance. It features a precise temperature-sensitive element that accurately detects temperature changes. The switch is also designed for easy installation and integration into the truck’s system, with a compact form factor that fits within various engine compartments.

Benefits

The Cummins 4327022 Temperature Switch offers several benefits, including improved engine performance through effective temperature management. It enhances safety by preventing engine overheating, which can lead to severe damage. Additionally, its reliable operation in various operating conditions ensures consistent performance and longevity.

Installation and Integration

Proper installation of the Cummins 4327022 Temperature Switch involves ensuring it is correctly positioned within the engine compartment to accurately monitor temperature. It should be securely mounted and connected to the appropriate electrical circuits. Following the manufacturer’s guidelines for installation will help ensure optimal performance and integration within the truck’s system.

Troubleshooting and Maintenance

Common issues with the Cummins 4327022 Temperature Switch may include inaccurate temperature readings or failure to activate the cooling system. Troubleshooting involves checking the electrical connections, ensuring the switch is properly mounted, and verifying the functionality of the temperature-sensitive element. Regular maintenance, such as inspecting for corrosion or damage, can help ensure the switch operates reliably over time.

Common Failure Modes

Temperature switches may fail due to various reasons, including electrical issues, mechanical wear, or exposure to extreme temperatures. Symptoms of failure may include the cooling fan not activating or the temperature gauge providing inaccurate readings. Addressing these issues promptly by replacing the switch or repairing electrical connections can help maintain engine performance.

Diagnostic Procedures

Diagnosing the Cummins 4327022 Temperature Switch involves using a multimeter to check for proper electrical continuity and ensuring the switch activates at the correct temperature. Professionals may also use diagnostic tools to monitor the switch’s performance within the engine management system, identifying any anomalies or failures.

Role in Engine Management Systems

The Cummins 4327022 Temperature Switch interacts with engine management systems by providing real-time temperature data. This information allows the system to make adjustments to engine operations, such as activating the cooling fan or adjusting fuel delivery, to maintain optimal performance and efficiency.

Temperature Switch Compatibility with Cummins Engines

The Temperature Switch part number 4327022, manufactured by Cummins, is designed to integrate seamlessly with various Cummins engine models. This component plays a crucial role in maintaining optimal engine performance by regulating temperature-related functions.

B3.3 Engine

For the B3.3 engine, the Temperature Switch ensures that the engine operates within its ideal temperature range. This is particularly important for maintaining fuel efficiency and preventing overheating, which can lead to engine damage.

K19 and K38 Engines

The K19 and K38 engines benefit from the Temperature Switch in similar ways. These engines, often used in heavy-duty applications, require precise temperature monitoring to ensure longevity and reliability. The Temperature Switch helps in managing the engine’s cooling system, ensuring that it neither overheats nor runs too cool, which can affect performance and fuel consumption.

K50 Engine

The K50 engine, another robust model in Cummins’ lineup, also relies on the Temperature Switch for effective temperature regulation. This engine’s demanding nature, often found in industrial and construction equipment, necessitates a reliable temperature control system. The Temperature Switch ensures that the engine maintains its operational efficiency and durability under various conditions.

By integrating the Temperature Switch into these engines, Cummins ensures that each model operates at peak efficiency, providing reliable performance across different applications.

Role of Part 4327022 Temperature Switch in Engine Systems

The Part 4327022 Temperature Switch is an integral component in various engine systems, ensuring optimal performance and safety. It is designed to monitor and regulate the temperature within the engine, providing essential data to the Control and Instrumentation systems.

Integration with Control Systems

In Control Systems, the Temperature Switch plays a significant role by providing real-time temperature readings. This data is vital for the control algorithms that manage engine performance, ensuring that the engine operates within safe temperature limits. The switch helps in adjusting the engine’s operation based on the temperature, thus enhancing efficiency and longevity.

Safety Mechanisms

The Temperature Switch is also a key element in Safety Systems. It triggers protective measures when the engine temperature exceeds predetermined thresholds. This could involve activating a cooling system or shutting down the engine to prevent damage. The switch’s quick response is essential in maintaining the engine’s integrity under varying operational conditions.

Engine Installation Kit

When included in an Engine Installation Kit, the Temperature Switch ensures that the engine is installed with all necessary monitoring components. This facilitates easier setup and integration into the overall engine system, providing immediate temperature monitoring capabilities from the onset of engine operation.

Instrumentation and Instrumentation Kit

In Instrumentation Systems, the Temperature Switch is a fundamental component. It feeds temperature data to the instrumentation panel, allowing engineers and operators to monitor engine health continuously. In an Instrumentation Kit, the switch is often accompanied by other sensors and gauges, creating a comprehensive monitoring setup.

Kit on Board Spares

As part of a Kit on Board Spares, the Temperature Switch ensures that replacement components are readily available. This is particularly important in scenarios where engine downtime needs to be minimized. Having a spare switch on hand allows for quick replacements in case of failure, ensuring continuous engine operation.

Safety Control Systems

In Safety Control Systems, the Temperature Switch works in conjunction with other safety components to maintain engine safety. It helps in implementing safety protocols that are triggered by temperature variations, thus playing a role in the overall safety strategy of the engine system.

Coolant Temperature Monitoring

Specifically, in Coolant Temperature systems, the switch monitors the temperature of the coolant circulating through the engine. This is vital for maintaining the engine’s thermal balance, as coolant temperature is a direct indicator of the engine’s thermal state.

Upfit Part

As an Upfit Part, the Temperature Switch can be added to existing engine systems to enhance their monitoring capabilities. This is particularly useful in retrofitting older engines with modern temperature monitoring features, improving their performance and safety.

Conclusion

The Cummins 4327022 Temperature Switch is a versatile component that enhances the functionality and safety of various engine systems. Its role in monitoring and regulating temperature is essential for the efficient and safe operation of engines across different applications.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.