This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4382850 Temperature Sensor is a specialized component designed for use in commercial trucks. Its purpose is to monitor the temperature of the engine coolant, providing data that helps maintain optimal engine performance. This sensor ensures that the engine operates within safe temperature ranges, contributing to the overall efficiency and longevity of the vehicle 4.

Basic Concepts of Temperature Sensors

Temperature sensors measure temperature changes and convert them into electrical signals. These sensors are integral to various automotive systems, where they help regulate engine performance, cabin comfort, and other functions. In automotive applications, temperature sensors typically use thermistors or thermocouples to detect temperature variations and send corresponding signals to the vehicle’s electronic control unit (ECU) 1.

Role of the 4382850 Temperature Sensor in Truck Operation

The Cummins 4382850 Temperature Sensor is designed to monitor and maintain the optimal engine temperature in commercial trucks. By providing real-time data on coolant temperature, this sensor allows the ECU to make necessary adjustments to fuel injection, ignition timing, and other parameters. This ensures that the engine operates efficiently and prevents overheating, which can lead to severe engine damage 2.

Key Features of the 4382850 Temperature Sensor

The Cummins 4382850 Temperature Sensor boasts several key features that enhance its performance in heavy-duty truck applications. Its robust design incorporates high-quality materials that withstand extreme temperatures and harsh operating conditions. The sensor offers high accuracy in temperature readings, ensuring reliable data for the ECU. Additionally, its compact design allows for easy integration into the engine system without requiring significant modifications 3.

Benefits of Using the 4382850 Temperature Sensor

Utilizing the Cummins 4382850 Temperature Sensor offers several advantages. It contributes to improved engine efficiency by ensuring that the engine operates within optimal temperature ranges. The sensor’s durability and accuracy enhance the overall reliability of the vehicle, reducing the likelihood of engine-related issues. Furthermore, its precise temperature monitoring capabilities help in maintaining the engine’s performance over time, leading to extended vehicle lifespan 4.

Installation and Integration

Proper installation of the Cummins 4382850 Temperature Sensor is crucial for its optimal functionality. The sensor should be installed in a location where it can accurately measure the coolant temperature, typically near the thermostat housing or within the coolant passage. It is important to follow the manufacturer’s guidelines to ensure that the sensor is securely mounted and properly connected to the ECU. Any necessary precautions, such as ensuring the sensor is not exposed to direct engine heat, should be taken to maintain its accuracy and longevity 1.

Troubleshooting Common Issues

Common issues with temperature sensors may include inaccurate readings, sensor malfunction, or electrical connection problems. To troubleshoot these issues, one should first verify the sensor’s installation and connections. Checking for any signs of physical damage or corrosion can also help identify potential problems. If the sensor readings are inconsistent, calibrating the sensor or replacing it may be necessary. Consulting the vehicle’s service manual can provide specific troubleshooting steps tailored to the Cummins 4382850 Temperature Sensor 2.

Maintenance Tips

Regular maintenance of the Cummins 4382850 Temperature Sensor is important to ensure its accurate performance and longevity. This includes periodic inspection for any signs of wear or damage, cleaning the sensor to remove any buildup that may affect its readings, and calibrating it as needed. Additionally, ensuring that the coolant system is free of contaminants and operates within the recommended temperature range can help maintain the sensor’s effectiveness 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, known for its innovation, quality, and commitment to customer satisfaction. The company’s expertise in engine manufacturing and technological advancements continues to drive its success in providing reliable and efficient power solutions for various applications 4.

Role of 4382850 Temperature Sensor in Engine Systems

The 4382850 Temperature Sensor is integral to the efficient operation of several engine systems, ensuring optimal performance and safety.

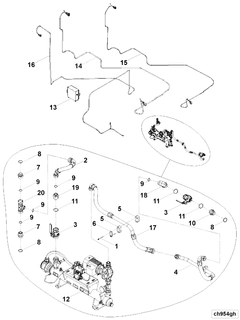

Integration with the Automatic Idle (AID) System

In the Automatic Idle (AID) system, the temperature sensor provides real-time data on engine temperature. This information allows the AID system to adjust idle speed dynamically. When the engine is cold, the AID system increases the idle speed to facilitate quicker warm-up. As the engine reaches operating temperature, the idle speed is reduced, promoting fuel efficiency and reducing emissions 1.

Function in the Coolant Heater System

The temperature sensor plays a significant role in the coolant heater system by monitoring the temperature of the engine coolant. During cold starts, the sensor signals the coolant heater to activate, warming the coolant before it circulates through the engine. This pre-warmed coolant reduces the time required for the engine to reach optimal operating temperature, enhancing overall engine performance and reducing wear on engine components 2.

Contribution to the Heater Starting System

In the heater starting system, the temperature sensor ensures that the engine starts efficiently in cold conditions. By providing accurate temperature readings, the sensor allows the system to determine the appropriate amount of heat required for the engine block and components. This precise control ensures that the engine starts smoothly and operates efficiently from the moment of ignition, improving driver comfort and engine longevity 3.

Role in the Engine Heater System

The temperature sensor is also vital in the engine heater system, where it monitors the temperature of the engine block and surrounding components. This data is used to control the activation and deactivation of the engine heater, ensuring that the engine is warmed to the optimal temperature before starting. This not only facilitates easier starting in cold weather but also protects the engine from the adverse effects of cold starts, such as increased wear and reduced efficiency 4.

Conclusion

The Cummins 4382850 Temperature Sensor is a critical component in maintaining the optimal performance and safety of commercial truck engines. Its accurate temperature monitoring capabilities ensure that the engine operates within safe temperature ranges, contributing to improved efficiency, reliability, and longevity of the vehicle. Proper installation, regular maintenance, and troubleshooting of common issues are essential to maximize the benefits of this sensor.

-

Auto Repair for Dummies: 2nd Edition, Deanna Sclar, For Dummies, 2008

↩ ↩ ↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011

↩ ↩ ↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010

↩ ↩ ↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.