4921322

Pressure Temperature Sensor

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4921322 Pressure Temperature Sensor is a component designed to monitor and maintain optimal conditions within the engine system of commercial trucks. Its role is significant in ensuring the engine operates efficiently and reliably under various conditions.

Basic Concepts of Pressure Temperature Sensors

A Pressure Temperature Sensor is a device that measures both pressure and temperature within a system. It functions by converting physical parameters into electrical signals, which are then used by the engine control unit (ECU) to adjust engine operations 1. This sensor plays a role in maintaining optimal engine performance by providing real-time data on pressure and temperature levels, allowing for precise control and adjustment of engine functions.

Purpose of the Cummins 4921322 Pressure Temperature Sensor

The Cummins 4921322 Pressure Temperature Sensor is specifically designed to monitor pressure and temperature levels within a truck’s engine system. By providing accurate and timely data to the ECU, it enables the system to make necessary adjustments to maintain optimal engine performance. This sensor plays a role in ensuring that the engine operates within safe parameters, enhancing both efficiency and reliability 2.

Key Features

The Cummins 4921322 Pressure Temperature Sensor is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. Its design includes precise calibration for accurate readings and a compact form factor for easy integration into the engine system. Additionally, it features corrosion-resistant materials, enhancing its performance in harsh operating environments 3.

Benefits

Utilizing the Cummins 4921322 Pressure Temperature Sensor offers several benefits. It contributes to improved engine performance by ensuring that the engine operates under optimal conditions. This sensor also plays a role in enhancing fuel efficiency, as the ECU can make more informed decisions based on real-time data. Furthermore, its reliable operation contributes to the overall durability and reliability of the engine system 4.

Installation and Integration

Proper installation of the Cummins 4921322 Pressure Temperature Sensor is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring it is securely mounted and correctly connected to the engine’s electrical system. Attention to detail during installation helps ensure that the sensor provides accurate readings and integrates seamlessly with the engine’s control systems.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are important for the continued reliable operation of the Cummins 4921322 Pressure Temperature Sensor. Common issues may include inaccurate readings or sensor failure, which can often be addressed by checking connections, cleaning the sensor, or replacing it if necessary. Adhering to recommended maintenance schedules and guidelines helps ensure the sensor remains in optimal condition.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality components that meet the demanding requirements of commercial and industrial applications. Their dedication to quality and performance is evident in their extensive range of automotive components, including the Cummins 4921322 Pressure Temperature Sensor.

Compatibility with Cummins Engines

The Pressure Temperature Sensor part number 4921322, manufactured by Cummins, is designed to fit a variety of Cummins engines. This sensor plays a crucial role in monitoring and regulating the engine’s pressure and temperature, ensuring optimal performance and longevity. Below is a detailed breakdown of the engines that are compatible with this sensor:

B Series Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- B6.7 CM2670 B164C

- F3.8 CM2350 F128C

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB3.9 CM2220 B107

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B140

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

ISD Series Engines

- ISD4.5 CM2220 D108

ISF Series Engines

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF4.5 CM2220 F123

ISG Series Engines

- ISG11 CM2880 G108

This sensor is engineered to seamlessly integrate with the specified engines, providing accurate data that helps maintain the engine’s efficiency and reliability. Each engine model listed above relies on the precise monitoring capabilities of the Pressure Temperature Sensor 4921322 to function optimally.

Role of Part 4921322 Pressure Temperature Sensor in Engine Systems

The Part 4921322 Pressure Temperature Sensor is an integral component in modern engine systems, providing essential data that contributes to the overall efficiency and performance of the engine. Its role can be understood in the context of several key engine components and systems.

Integration with the Engine Control Module (ECM)

The Pressure Temperature Sensor is directly connected to the Engine Control Module (ECM), which is the brain of the engine management system. The sensor continuously monitors and reports pressure and temperature data to the ECM. This information allows the ECM to make precise adjustments to fuel injection, ignition timing, and other critical parameters, ensuring optimal engine performance under varying conditions.

Contribution to Exhaust Gas Recirculation (EGR) System

In the Exhaust Gas Recirculation (EGR) system, the Pressure Temperature Sensor plays a significant role by providing accurate data on the pressure and temperature of the exhaust gases being recirculated back into the intake manifold. This data helps the ECM fine-tune the EGR valve operation, ensuring that the correct amount of exhaust gas is recirculated. Proper EGR management reduces nitrogen oxides (NOx) emissions and improves fuel efficiency.

Influence on Fuel Injection and Air-Fuel Ratio

The sensor’s data is vital for maintaining the correct air-fuel ratio. By monitoring the intake manifold’s pressure and temperature, the ECM can adjust the fuel injection timing and quantity. This ensures that the engine runs efficiently, with minimal emissions and maximum power output.

Enhancing Engine Performance and Efficiency

Accurate pressure and temperature readings from the sensor allow the ECM to optimize various engine parameters in real-time. This includes adjusting the ignition timing for better combustion efficiency and reducing the likelihood of engine knocking. The sensor’s data also aids in the management of the variable valve timing system, if present, further enhancing engine performance and fuel economy.

Supporting Diagnostic and Maintenance Functions

The Pressure Temperature Sensor contributes to the engine’s diagnostic capabilities by providing continuous data that can be used to detect anomalies or inefficiencies in the engine’s operation. This data is invaluable during routine maintenance checks, helping mechanics identify potential issues before they become significant problems.

Conclusion

In summary, the Part 4921322 Pressure Temperature Sensor is a key component in modern engine systems, providing essential data that enables the ECM to make real-time adjustments for optimal engine performance, efficiency, and emissions control. Its integration with various engine components underscores its importance in the overall engine management system.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩

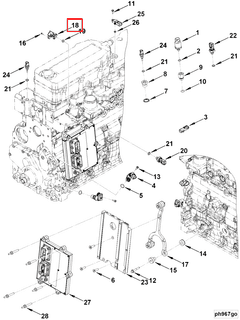

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 4903482 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.