This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4010051 Temperature Sensor is a vital component in the operation of commercial trucks. This sensor is designed to monitor the temperature of the engine coolant, providing data to the engine management system. Its role is significant in ensuring the engine operates within optimal temperature ranges, which is essential for maintaining performance and longevity.

Basic Concepts of Temperature Sensors

Temperature sensors are devices that measure temperature changes and convert them into electrical signals. These sensors are integral to various automotive systems, providing data that helps regulate engine performance, cabin comfort, and other functions. They operate based on the principle of thermal expansion or resistance changes in materials when subjected to temperature variations 1.

Purpose of the 4010051 Temperature Sensor

This Cummins part plays a role in the operation of a truck by monitoring the temperature of the engine coolant. This data is transmitted to the engine management system, which uses it to make adjustments to fuel injection, ignition timing, and other parameters. By ensuring the engine remains within the optimal temperature range, the sensor helps maintain engine efficiency and prevent overheating.

Key Features

The 4010051 Temperature Sensor is characterized by its robust design and high-quality materials. It features a durable housing that protects the sensitive internal components from harsh engine environments. The sensor utilizes advanced technology to provide accurate and reliable temperature readings, ensuring the engine management system receives precise data.

Benefits of Using the 4010051 Temperature Sensor

The advantages of using this Cummins part include improved engine performance, enhanced fuel efficiency, and reliable temperature monitoring. Accurate temperature data allows the engine management system to optimize fuel injection and ignition timing, leading to better overall performance and reduced fuel consumption. Additionally, consistent temperature monitoring helps prevent engine damage from overheating 2.

Installation and Integration

Installing the 4010051 Temperature Sensor involves placing it in the engine coolant passage where it can accurately measure temperature. Integration into the truck’s engine system requires connecting it to the engine management system, ensuring it is properly secured and sealed to prevent coolant leaks. Following manufacturer guidelines during installation is important to ensure accurate readings and system compatibility.

Troubleshooting Common Issues

Common issues with the 4010051 Temperature Sensor may include inaccurate temperature readings or sensor failure. These problems can often be identified through diagnostic tools that monitor sensor output. Resolving these issues may involve recalibrating the sensor, checking for wiring issues, or replacing the sensor if it is faulty.

Maintenance Tips

To ensure the longevity and optimal performance of the 4010051 Temperature Sensor, regular maintenance is recommended. This includes periodic checks for secure mounting, inspecting wiring and connections for damage, and cleaning the sensor to remove any buildup that could affect its accuracy. Adhering to these maintenance practices helps ensure the sensor continues to provide reliable temperature data.

Role in Engine Management

The 4010051 Temperature Sensor interacts with the engine management system by providing real-time temperature data. This information is used by the system to make adjustments to various engine parameters, ensuring the engine operates efficiently and within safe temperature limits. The sensor’s accurate readings are crucial for the engine management system to function correctly.

Impact on Fuel Efficiency

Accurate temperature monitoring by the 4010051 Temperature Sensor contributes to improved fuel efficiency in trucks. By providing precise temperature data, the engine management system can optimize fuel injection and ignition timing. This optimization leads to more efficient combustion, reducing fuel consumption and enhancing overall engine performance 3.

Compatibility with Cummins Engines

The Temperature Sensor 4010051, manufactured by Cummins, is a critical component designed to monitor and regulate engine temperature across various Cummins engine models. This sensor ensures optimal performance and longevity by providing essential data to the engine control unit (ECU).

ISC CM554 and ISL CM554

The ISC CM554 and ISL CM554 engines both utilize the Temperature Sensor 4010051 to maintain precise temperature readings. These engines are known for their robust design and are commonly used in heavy-duty applications. The sensor’s role in these engines is to provide real-time temperature feedback, which is crucial for preventing overheating and ensuring efficient operation.

ISC CM850 and QSC8.3 CM850 (CM2850)

The ISC CM850 and QSC8.3 CM850 (CM2850) engines also integrate the Temperature Sensor 4010051. These engines are part of Cummins’ higher power output range, often used in demanding industrial and commercial applications. The sensor’s accuracy in these engines is vital for maintaining peak performance and safeguarding against thermal stress.

ISL9 CM2150 SN and QSL9 CM554

The ISL9 CM2150 SN and QSL9 CM554 engines are equipped with the Temperature Sensor 4010051 to ensure reliable temperature monitoring. These engines are designed for heavy-duty use and are often found in applications requiring substantial power and durability. The sensor’s integration in these models is essential for the ECU to make informed decisions regarding engine operation and protection.

QSC8.3 CM554

The QSC8.3 CM554 engine also incorporates the Temperature Sensor 4010051. This engine is known for its versatility and is used in various applications, from construction to agricultural machinery. The sensor’s role in this engine is to provide critical temperature data, ensuring the engine operates within safe parameters and enhancing overall efficiency.

Role of 4010051 Temperature Sensor in Engine Systems

The 4010051 Temperature Sensor is an essential component in maintaining the optimal performance of various engine systems. Its primary function is to monitor and relay temperature data from critical engine components to the engine control unit (ECU). This data is vital for the ECU to make real-time adjustments to fuel injection, ignition timing, and other parameters to ensure efficient and safe engine operation.

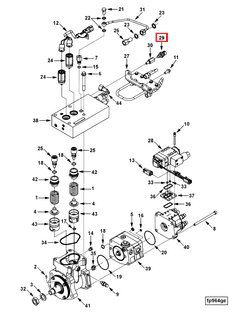

Integration with Key Engine Components

-

Fuel Injection Pump: The temperature sensor provides feedback on the temperature of the fuel, which is crucial for the fuel injection pump to deliver the correct amount of fuel. Accurate temperature readings help in adjusting the viscosity of the fuel, ensuring precise fuel delivery and combustion.

-

Fuel Pump: Temperature data from the sensor assists in regulating the fuel pump’s performance. By monitoring the temperature of the fuel, the ECU can adjust the fuel pump’s operation to maintain consistent fuel pressure and flow, which is essential for stable engine performance.

-

Injector: The temperature sensor plays a role in the operation of the injectors by providing temperature-related data that helps the ECU fine-tune the injection timing and duration. This ensures that the fuel is atomized correctly and combusts efficiently.

-

Cam Housing Module: In engines where the cam housing module is present, the temperature sensor helps in monitoring the temperature around the camshaft. This information is used to adjust valve timing and other camshaft-related functions to optimize engine performance and longevity.

-

Accumulator: For systems that include an accumulator, the temperature sensor ensures that the hydraulic fluid within remains at an optimal temperature. This is important for maintaining the accumulator’s efficiency and the overall performance of the fuel injection system.

-

Plumbing and Parts: The sensor’s data is also used to monitor the temperature of various plumbing components and parts within the engine system. This helps in preventing overheating and ensuring that all components operate within their specified temperature ranges.

-

Sensor Kit: When part of a comprehensive sensor kit, the 4010051 Temperature Sensor works in conjunction with other sensors to provide a complete picture of the engine’s operating conditions. This holistic approach allows for more precise control and better overall engine management.

By providing accurate temperature data, the 4010051 Temperature Sensor enables the ECU to make informed decisions that enhance engine performance, fuel efficiency, and reliability.

Conclusion

The Cummins 4010051 Temperature Sensor is a critical component in the operation of commercial trucks, ensuring that engines operate within optimal temperature ranges. Its accurate temperature readings enable the engine management system to make real-time adjustments, enhancing engine performance, fuel efficiency, and reliability. Regular maintenance and proper installation are essential to ensure the sensor continues to provide reliable data, contributing to the overall efficiency and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.