4088712

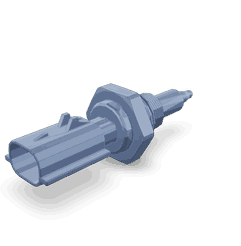

Temperature Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4088712 Temperature Sensor is a specialized component designed for use in commercial trucks. Its purpose is to monitor the temperature within the engine system, providing data that helps maintain optimal operating conditions. This sensor plays a role in ensuring the engine operates efficiently and reliably, contributing to overall vehicle performance and longevity.

Basic Concepts of Temperature Sensors

A temperature sensor measures temperature or detects changes in temperature and converts these measurements into electrical signals. These sensors operate based on various principles, including thermocouples, thermistors, and resistance temperature detectors (RTDs). In automotive systems, temperature sensors are used to monitor engine temperature, coolant temperature, and oil temperature, among other applications. They provide data to the vehicle’s electronic control unit (ECU), which uses this information to adjust engine parameters and ensure efficient operation 1.

Function and Role in Truck Operation

The Cummins 4088712 Temperature Sensor is integral to monitoring and maintaining optimal operating conditions within a truck’s engine system. By accurately measuring the temperature of critical components, this sensor allows the ECU to make real-time adjustments to fuel injection, ignition timing, and other parameters. This ensures that the engine operates within safe temperature ranges, preventing overheating and potential damage. Additionally, the sensor helps in diagnosing engine issues by providing precise temperature data, which can indicate problems such as coolant leaks or faulty thermostats 2.

Key Features

The Cummins 4088712 Temperature Sensor is designed with several key features that enhance its performance and reliability. It is constructed using high-quality materials that can withstand the harsh conditions within an engine environment. The sensor incorporates advanced technological specifications, such as a robust housing and precise temperature measurement capabilities. These features ensure accurate and consistent performance, even under extreme operating conditions.

Benefits of Using the Cummins 4088712 Temperature Sensor

Utilizing the Cummins 4088712 Temperature Sensor offers several advantages. It contributes to improved engine performance by ensuring that the engine operates within optimal temperature ranges. This leads to enhanced fuel efficiency, as the ECU can make more accurate adjustments based on real-time temperature data. Additionally, the sensor helps prolong the lifespan of engine components by preventing overheating and related damage. Overall, it plays a role in maintaining the reliability and efficiency of the truck’s engine system.

Installation and Integration

Proper installation and integration of the Cummins 4088712 Temperature Sensor are vital for its effective operation. The sensor should be installed in a location where it can accurately measure the temperature of the targeted component, such as the engine block or coolant passage. It is important to follow manufacturer guidelines to ensure correct placement and secure mounting. Additionally, any necessary electrical connections should be made according to specified procedures to avoid issues such as short circuits or incorrect readings.

Troubleshooting Common Issues

Common problems associated with temperature sensors include inaccurate readings, sensor failure, and electrical issues. To troubleshoot these problems, begin by verifying the sensor’s installation and connections. Ensure that the sensor is correctly positioned and that all electrical connections are secure and free from corrosion. If the sensor provides inaccurate readings, it may need to be calibrated or replaced. Consulting the vehicle’s service manual can provide specific diagnostic procedures and troubleshooting steps.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4088712 Temperature Sensor, regular maintenance is recommended. This includes periodic inspection of the sensor and its connections to ensure they remain intact and free from corrosion. Cleaning the sensor and its surrounding area can prevent buildup that might affect its accuracy. Additionally, following the manufacturer’s recommended service intervals for sensor replacement can help maintain accurate temperature monitoring and overall engine health.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the automotive industry for producing high-quality, reliable components. The company’s product range includes engines, powertrains, and related technologies for various applications, including commercial trucks, construction equipment, and industrial uses. Cummins is known for its commitment to innovation, quality, and customer satisfaction.

Temperature Sensor 4088712 Compatibility with Cummins Engines

The Temperature Sensor part number 4088712, manufactured by Cummins, is designed to fit a variety of Cummins engines. This sensor plays a role in monitoring and regulating the engine’s temperature, ensuring optimal performance and preventing overheating.

ISB Series

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB6.7 CM2250

The ISB series engines, including the ISB (Chrysler), ISB CM2150, ISB CM850, and ISB6.7 CM2250, are equipped with the Temperature Sensor 4088712. This sensor is integral in maintaining the engine’s thermal efficiency and ensuring that the engine operates within safe temperature limits.

ISC Series

- ISC CM2150

- ISC8.3 CM2250

The ISC series engines, specifically the ISC CM2150 and ISC8.3 CM2250, also utilize the Temperature Sensor 4088712. This sensor is essential for these engines to monitor and adjust the temperature, which is critical for maintaining performance and preventing damage.

ISL Series

- ISL CM2150

- ISL G CM2180

- ISL9 CM2250

The ISL series engines, including the ISL CM2150, ISL G CM2180, and ISL9 CM2250, are compatible with the Temperature Sensor 4088712. This sensor ensures that these engines maintain the correct operating temperature, contributing to their overall efficiency and longevity.

ISM Series

- ISM CM570/870

- ISM CM876

The ISM series engines, such as the ISM CM570/870 and ISM CM876, are designed to work with the Temperature Sensor 4088712. This sensor is vital for these engines to regulate temperature, ensuring they run smoothly and efficiently.

ISX Series

- ISX CM870

- ISX CM871

- ISX12 G CM2180 EJ

The ISX series engines, including the ISX CM870, ISX CM871, and ISX12 G CM2180 EJ, are equipped with the Temperature Sensor 4088712. This sensor is crucial for these high-performance engines to monitor and maintain the optimal operating temperature, ensuring peak performance and reliability.

QSC/QSL Series

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

The QSC9 CM2250/QSL9 CM2250 and QSL9 CM2250 engines are compatible with the Temperature Sensor 4088712. This sensor is essential for these engines to regulate temperature, ensuring they operate within safe limits and maintain efficiency.

QSF/QSM Series

- QSF2.8 CM2880 F114

- QSM11 CM876

The QSF2.8 CM2880 F114 and QSM11 CM876 engines are designed to use the Temperature Sensor 4088712. This sensor is critical for these engines to monitor and maintain the correct operating temperature, ensuring they perform reliably and efficiently.

Role of Part 4088712 Temperature Sensor in Engine Systems

The 4088712 Temperature Sensor is an essential component that integrates with various engine systems to ensure optimal performance and efficiency. Its primary function is to monitor and relay temperature data to the Engine Control Module (ECM), which then adjusts engine operations accordingly.

Integration with Key Engine Components

-

Air Intake Connection: The temperature sensor is often placed near the air intake connection to measure the temperature of the incoming air. Accurate air temperature readings are vital for the ECM to calculate the correct air-fuel mixture, ensuring efficient combustion.

-

Arrangement with Turbocharger: In turbocharged engines, the sensor is strategically arranged to monitor the temperature before and after the turbocharger. This data helps in managing the turbocharger’s performance, preventing overheating, and optimizing boost levels.

-

Module Interaction: The sensor continuously sends temperature data to the ECM. The module uses this information to make real-time adjustments to fuel injection, ignition timing, and other critical parameters, enhancing overall engine performance and fuel efficiency.

-

Plumbing and Exhaust Recirculation Air: Within the plumbing system, the temperature sensor monitors the temperature of the Exhaust Gas Recirculation (EGR) air. This feedback loop allows the ECM to control the EGR valve more effectively, reducing emissions and improving combustion efficiency.

-

Recirculation and Exhaust Systems: The sensor also plays a role in the recirculation process by providing temperature data that aids in the management of exhaust gases. This ensures that the recirculated exhaust gases are within the optimal temperature range, contributing to lower emissions and better engine performance.

Conclusion

The Cummins 4088712 Temperature Sensor is a critical component in maintaining the efficiency and reliability of commercial truck engines. By accurately monitoring temperature, this sensor enables the ECU to make necessary adjustments to engine parameters, ensuring optimal performance and preventing potential damage. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this sensor.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.