This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

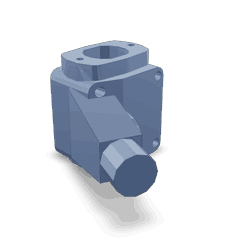

The Cummins 3013610 Thermostat Housing is a critical component in the engine cooling systems of commercial trucks. It houses the thermostat, which regulates coolant flow to maintain optimal engine temperature. This part ensures the integrity of the cooling system by providing a secure environment for the thermostat and facilitating efficient coolant passage 2.

Basic Concepts of Thermostat Housing

A thermostat housing encloses the thermostat within the engine cooling system, allowing coolant to flow into and out of the engine block based on temperature. When the engine is cold, the thermostat remains closed, restricting coolant flow to allow quick warm-up. As the engine temperature rises, the thermostat opens, permitting coolant circulation through the engine and radiator to dissipate heat and maintain a stable operating temperature 1.

Purpose of the 3013610 Thermostat Housing

The Cummins 3013610 Thermostat Housing is essential for maintaining optimal engine temperature in trucks. It prevents overheating or running too cold, which can lead to inefficient performance and potential damage. By providing a secure and precise environment for the thermostat, this housing enhances the efficiency and reliability of the engine cooling system 3.

Key Features

The Cummins 3013610 Thermostat Housing is known for its durable construction and precise engineering. It is designed to withstand the rigors of commercial truck operation, ensuring long-term reliability. The housing is engineered to fit specific Cummins engine models, ensuring compatibility and efficient performance. Its design allows for easy installation and maintenance, contributing to overall ease of use in a commercial setting 4.

Benefits

Using the Cummins 3013610 Thermostat Housing offers several benefits. It contributes to improved engine efficiency by ensuring the engine operates within the optimal temperature range. This housing provides reliable temperature regulation, which is vital for the longevity and performance of the engine. Additionally, its durable construction ensures long-term durability, reducing the need for frequent replacements and maintenance 2.

Installation Considerations

Proper installation of the Cummins 3013610 Thermostat Housing is crucial for its effectiveness. The process involves using the necessary tools to remove the old housing and install the new one, ensuring a secure fit. It is important to follow the manufacturer’s guidelines for removal and replacement to avoid damaging the component or the engine. Ensuring a secure fit helps in preventing leaks and maintaining the integrity of the cooling system 4.

Troubleshooting Common Issues

Common issues associated with thermostat housings include leaks and malfunctions. Leaks can occur due to worn gaskets or improper installation, while malfunctions may be caused by a faulty thermostat or blockages in the coolant passages. Troubleshooting steps include inspecting the housing and gaskets for wear, ensuring the thermostat is functioning correctly, and checking for any obstructions in the coolant passages. Addressing these issues promptly helps in maintaining the efficiency of the cooling system 3.

Maintenance Tips

Regular maintenance of the Cummins 3013610 Thermostat Housing is important for ensuring its longevity and performance. This includes inspecting the housing and gaskets at regular intervals for signs of wear or damage. Cleaning the housing and ensuring that all connections are secure can help in preventing leaks and maintaining efficient coolant flow. Replacing worn or damaged components promptly is important for the continued reliability of the cooling system 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various industries, including transportation, construction, and power generation. Cummins’ commitment to quality and customer satisfaction has made it a trusted name in the industry.

Thermostat Housing (Part 3013610) Compatibility with Cummins Engines

The Thermostat Housing part number 3013610, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is integral in regulating the engine’s temperature by controlling the flow of coolant.

N14 Mechanical Engine

The Thermostat Housing part 3013610 is specifically engineered to fit the N14 Mechanical engine. This engine is known for its robust design and reliability, often used in heavy-duty applications. The housing ensures that the coolant flows correctly, maintaining optimal engine temperature and preventing overheating.

NH/NT 855 Engines

Similarly, the Thermostat Housing part 3013610 is also compatible with the NH/NT 855 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, widely used in various industrial and commercial applications. The housing’s design allows for efficient coolant circulation, which is crucial for the engine’s longevity and performance.

Compatibility Summary

- N14 Mechanical Engine: Ensures proper coolant flow and temperature regulation.

- NH/NT 855 Engines: Provides efficient coolant circulation, essential for maintaining engine performance and longevity.

By using the Thermostat Housing part 3013610, owners of these Cummins engines can be assured of reliable engine operation and enhanced durability.

Understanding the Integration of Thermostat Housing (Part 3013610) in Engine Systems

The thermostat housing (part 3013610) is an integral component in the thermal management system of an engine. It is designed to encase the thermostat, which regulates the flow of coolant to the engine based on its temperature. This housing ensures a secure fit and proper sealing, preventing coolant leaks and maintaining system integrity.

Connection to Water Outlet

The thermostat housing is directly connected to the water outlet. This connection is vital for the circulation of coolant from the engine to the radiator. The water outlet connection allows for the controlled release of hot coolant, which is then replaced by cooler fluid, ensuring the engine operates within optimal temperature ranges.

Integration with EBM Housing

In engines equipped with an Electric Coolant Pump (ECP) or Electric Water Pump (EWP), often referred to as EBM (Electric Coolant/Water Pump), the thermostat housing is integrated with the EBM housing. This integration allows for precise control over coolant flow, enhancing engine efficiency and performance. The EBM housing works in conjunction with the thermostat to manage coolant circulation based on engine demand and temperature conditions.

Relationship with Thermostat and Mounting Components

The thermostat housing encases the thermostat, which is a temperature-sensitive valve. The housing provides a mounting surface for the thermostat, ensuring it is securely positioned within the engine’s cooling system. Additionally, the housing thermostat and mounting components work together to maintain a consistent engine temperature, which is essential for engine longevity and performance.

Role in Overall Cooling System

The thermostat housing, along with its associated components such as the thermostat and water outlet connection, plays a significant role in the overall cooling system of the engine. It ensures that the coolant is efficiently circulated through the engine block, cylinder head, and radiator. This circulation helps in dissipating heat, preventing overheating, and maintaining engine efficiency.

Conclusion

In summary, the thermostat housing (part 3013610) is a key component that interfaces with various parts of the engine’s cooling system, including the water outlet, EBM housing, thermostat, and mounting components. Its proper integration and function are essential for maintaining engine temperature and ensuring optimal performance.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles (National Academy of Sciences, 2010).

↩ -

Klaus Mollenhauer and Helmut Tschoeke, Handbook of Diesel Engines (Springer, 2010).

↩ ↩ -

Wolf-Henning Schneider, Pistons and Engine Testing (Springer Nature, 2016).

↩ ↩ -

General Information, Troubleshooting and Repair Manual, Bulletin Number 3666410.

↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.