This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

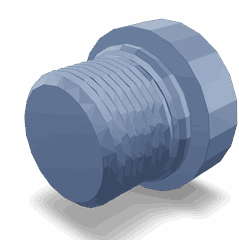

The Cummins 3286621 Threaded Plug is a component designed for use in commercial truck operations. Its primary role is to seal openings in various parts of the truck’s engine or system, preventing the escape of fluids or gases. A threaded plug, in general, is a mechanical device used to seal threaded holes. It is commonly employed in automotive components to ensure the integrity of fluid and gas pathways within engines and other mechanical systems 1.

Basic Concepts of Threaded Plugs

Threaded plugs are designed with external threads that match the internal threads of the holes they are intended to seal. Their function is to provide a secure, leak-proof closure. In automotive systems, threaded plugs are utilized in a variety of applications, including sealing oil passages, coolant systems, and fuel lines. They operate by being screwed into place, creating a tight seal that prevents the leakage of fluids or gases, thus maintaining the efficiency and safety of the system 2.

Purpose of the Cummins 3286621 Threaded Plug

The Cummins 3286621 Threaded Plug serves a specific role in truck operations by sealing openings in the engine or other systems. This plug contributes to the overall functionality and efficiency of the truck by ensuring that fluids and gases remain contained within their designated pathways. Proper sealing is vital for maintaining system pressure, preventing contamination, and ensuring the longevity of the engine components 3.

Key Features

The Cummins 3286621 Threaded Plug is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials that offer resistance to corrosion and wear. The plug features a specific thread type that ensures a secure fit within the corresponding threaded hole. Additionally, it may include unique design elements such as a tapered seat or O-ring groove to improve sealing capabilities.

Benefits

Using the Cummins 3286621 Threaded Plug offers several advantages. Its design provides improved sealing, which helps maintain system integrity and efficiency. The material composition offers resistance to corrosion, extending the plug’s lifespan. Additionally, the plug’s durability contributes to reduced maintenance requirements and operational efficiency for the truck.

Installation Process

Proper installation of the Cummins 3286621 Threaded Plug is crucial for optimal performance. The installation process involves screwing the plug into the designated threaded hole. It is important to use the correct torque settings to ensure a secure fit without over-tightening, which could damage the threads or the plug itself. Proper alignment is also necessary to achieve an effective seal.

Troubleshooting and Maintenance

Common issues with threaded plugs may include leaks due to improper installation or wear over time. Troubleshooting steps involve checking the plug’s fit and condition, ensuring it is properly torqued, and inspecting for signs of wear or damage. Regular maintenance, such as periodic inspection and replacement when necessary, can prolong the life of the plug and ensure continued reliable performance.

Compatibility and Usage

The Cummins 3286621 Threaded Plug is designed for specific applications within Cummins engines and systems. It is compatible with various components where sealing is required. Understanding its typical applications and how it integrates with other parts of the engine or system is important for ensuring proper function and efficiency.

Safety Considerations

When handling and installing the Cummins 3286621 Threaded Plug, it is important to follow safety guidelines to avoid injury or damage. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before installation, and using the correct tools to avoid over-tightening or cross-threading.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. The company has a long history of innovation and commitment to quality, providing a wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in its comprehensive product range and the trust it has earned among professionals in the industry.

Threaded Plug 3286621 Compatibility with Cummins Engines

The Cummins-manufactured Threaded Plug part number 3286621 is designed to fit seamlessly into various Cummins engine models. This part is crucial for ensuring the integrity and functionality of the engine’s systems. Below is a detailed overview of the engines with which this part is compatible:

-

6B5.9 Engine: The 3286621 threaded plug is engineered to fit perfectly within the 6B5.9 engine, providing a secure seal that prevents leaks and maintains system pressure. This compatibility ensures that the engine operates efficiently and reliably.

-

X15 CM2350 X116B Engine: Similarly, the 3286621 threaded plug is also compatible with the X15 CM2350 X116B engine. This part is designed to integrate smoothly into the engine’s architecture, ensuring that all connections are tight and secure. Its use in this engine model helps maintain optimal performance and longevity.

These threaded plugs are essential components in the engine’s design, ensuring that all threaded connections are sealed properly. Their compatibility across different engine models highlights the versatility and reliability of Cummins parts in maintaining engine integrity.

Role of Part 3286621 Threaded Plug in Engine Systems

The threaded plug, identified as part 3286621, is an essential component in various engine systems, contributing to the overall functionality and efficiency of the engine. Its role can be observed in the following components:

Filter Systems

In filter systems, the threaded plug is utilized to seal openings after maintenance or replacement procedures. It ensures that contaminants are effectively kept out, maintaining the integrity of the filtration process. This is particularly important in fuel and oil filters, where the purity of the fluid directly impacts engine performance and longevity.

Fuel Systems

Within fuel systems, the threaded plug is employed to seal off sections of the fuel line during repairs or modifications. This prevents fuel leakage and ensures that the system remains pressurized, which is vital for consistent fuel delivery to the engine. Proper sealing is also important for maintaining the correct fuel-to-air ratio, which is essential for optimal combustion.

Oil Pans

In the context of oil pans, the threaded plug is often used to seal inspection or drain ports. This ensures that the oil remains contained within the pan, preventing leaks that could lead to oil loss and potential engine damage. Additionally, it helps in maintaining the correct oil level, which is necessary for adequate lubrication of engine components.

Oil Systems

For oil systems, the threaded plug plays a role in sealing various ports and passages within the engine block and oil galleries. This is important for maintaining oil pressure, which is essential for the lubrication of moving parts. Effective sealing also prevents oil contamination, ensuring that the lubricant remains clean and effective throughout its service life.

Conclusion

In summary, the threaded plug (part 3286621) is a versatile component that enhances the reliability and efficiency of engine systems by ensuring proper sealing and containment of fluids. Its compatibility with various Cummins engine models and its role in critical engine systems underscore its importance in maintaining engine integrity and performance.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Asef, Pedram, Padmanaban, Sanjeevikumar, and Lapthorn, Andrew. Modern Automotive Electrical Systems. Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.