This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

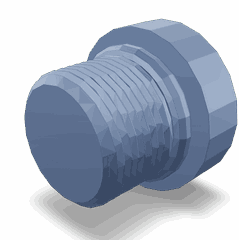

The Cummins 3336642 Threaded Plug is a specialized component for heavy-duty truck maintenance and operation. This part plays a role in the engine or system by sealing specific openings, contributing to the vehicle’s efficiency and reliability. Understanding its function is essential for maintaining the performance standards of heavy-duty trucks 1.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in engines or systems. They are screwed into place, creating a secure barrier that prevents the escape of fluids or gases. These plugs are vital in various automotive applications, ensuring the integrity of the system by maintaining pressure and preventing leaks 2.

Purpose of the Cummins 3336642 Threaded Plug

This Cummins part is engineered to seal specific openings in the truck’s engine or system, ensuring the internal environment remains consistent. It maintains the pressure and fluid levels necessary for optimal engine performance 3.

Key Features

The Cummins 3336642 is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring resistance to wear and corrosion. The plug features a specific thread type for a secure fit within the engine or system it is designed for. Additionally, unique design elements contribute to its effectiveness in sealing and durability 4.

Benefits of Using the Cummins 3336642 Threaded Plug

Incorporating this part into truck maintenance routines offers several advantages. It provides improved sealing, crucial for maintaining engine efficiency. The plug’s durable construction ensures long-term reliability, potentially leading to cost savings over time by reducing the need for frequent replacements.

Installation Process

Installing the Cummins 3336642 requires following a step-by-step process to ensure a secure fit. The process involves using specific tools to screw the plug into place. Best practices include ensuring the area is clean and free of debris before installation and tightening the plug to the manufacturer’s specified torque settings to avoid over-tightening or under-tightening.

Troubleshooting Common Issues

Common issues associated with threaded plugs include leaks or difficulty in removal. Troubleshooting these problems involves checking the plug for signs of wear or damage and ensuring it is properly seated. In cases of difficulty in removal, using the appropriate tools and techniques can help avoid damaging the plug or the surrounding components.

Maintenance Tips

Regular maintenance of the Cummins 3336642 is important for ensuring its continued effectiveness. This includes periodic inspections for signs of wear or damage, cleaning the plug and surrounding area to prevent buildup, and considering replacement if any issues are detected during inspections.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its wide range of products and commitment to quality. With a history of innovation and excellence, Cummins has built a reputation for producing reliable and high-performance components, including the 3336642 Threaded Plug.

Role of Part 3336642 Threaded Plug in Engine Systems

In the context of engine systems, the 3336642 Threaded Plug is utilized in various components to ensure the efficient and reliable operation of the engine.

Assembly Flange

The assembly flange connects different parts of the engine, ensuring a secure and tight fit. The threaded plug seals any openings or passages within the flange, preventing any unwanted leakage of fluids or gases and maintaining the integrity of the assembly.

Lubricating Oil Assembly Pump

In the lubricating oil assembly pump, the threaded plug seals off specific ports or passages. This is essential for maintaining the correct pressure and flow of lubricating oil throughout the engine. By ensuring that oil does not escape from unintended areas, the threaded plug helps in delivering a consistent and reliable supply of lubrication to critical engine components.

Pump

Within the pump itself, the threaded plug is used to seal various inlets and outlets. This sealing is vital for the pump’s efficiency, as it ensures that the fluid being pumped is directed correctly without any loss. The threaded plug helps in maintaining the pump’s operational parameters, such as pressure and flow rate.

Lubricating Oil

In the lubricating oil system, the threaded plug is often used to seal off passages within the oil galleries or channels. This ensures that the lubricating oil reaches all necessary parts of the engine without any leakage. The proper sealing provided by the threaded plug is essential for maintaining the correct oil levels and pressure, which are critical for the engine’s smooth operation and protection against wear and tear.

Conclusion

The Cummins 3336642 Threaded Plug is a critical component in maintaining the efficiency and reliability of heavy-duty truck engines. Its role in sealing various engine components ensures the integrity of the system, contributing to the overall performance and longevity of the vehicle.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.