This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

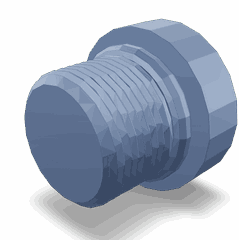

The Cummins 3336644 Threaded Plug is a component designed for use in commercial truck operations. It serves a specific function within the truck’s engine or other systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

A threaded plug is a fastener with an external thread that is screwed into a matching internal thread. Its primary function is to seal openings, prevent leaks, and secure components in place. In automotive and industrial settings, threaded plugs are utilized in various applications, including sealing engine block passages, securing components, and preventing fluid leaks 1.

Purpose of the Cummins 3336644 Threaded Plug

The Cummins 3336644 Threaded Plug is specifically designed to play a role in the operation of a truck. It functions within the engine or other systems by sealing specific passages or openings. This sealing action helps maintain system integrity, prevent leaks, and ensure that fluids or gases remain contained within their designated pathways.

Key Features

The Cummins 3336644 Threaded Plug is characterized by several key features that enhance its functionality and durability. These include its material composition, typically a robust metal alloy that resists corrosion and wear. The thread type is designed to provide a secure fit, ensuring a tight seal. Additionally, the plug’s design specifications are tailored to meet the demanding conditions of commercial truck operations.

Benefits of Using the Cummins 3336644 Threaded Plug

Utilizing the Cummins 3336644 Threaded Plug offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The plug’s design facilitates ease of installation, allowing for quick and efficient maintenance procedures. Furthermore, its reliable sealing capability contributes to enhanced system performance and efficiency.

Installation Process

Proper installation of the Cummins 3336644 Threaded Plug involves several steps. Begin by ensuring the mating thread is clean and free of debris. Apply a suitable thread sealant to the plug’s threads to enhance the seal. Carefully screw the plug into the designated opening, using a torque wrench to achieve the recommended torque specification. This ensures a secure fit without over-tightening, which could damage the threads.

Troubleshooting Common Issues

Common problems associated with threaded plugs include leaks, difficulty in removal, and thread damage. To address leaks, verify the plug is properly installed and consider reapplying thread sealant. If removal is challenging, use a plug extractor tool to avoid damaging the threads. In cases of thread damage, it may be necessary to repair or replace the mating thread to ensure a proper seal.

Maintenance Tips

Regular maintenance of the Cummins 3336644 Threaded Plug is crucial for ensuring its longevity and optimal performance. Inspect the plug during routine maintenance checks for signs of wear or damage. Clean the plug and its mating thread to remove any debris or buildup. If the plug shows signs of corrosion or significant wear, consider replacing it to maintain system integrity.

Role in Engine and System Integrity

The Cummins 3336644 Threaded Plug contributes to the overall integrity and functionality of the truck’s engine and related systems by providing a reliable seal. This seal helps maintain system pressure, prevent leaks, and ensure that fluids or gases remain within their intended pathways. By doing so, the plug plays a role in supporting the efficient operation of the engine and other critical systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators 2.

Threaded Plug 3336644 Compatibility with Cummins Engines

The Cummins Threaded Plug 3336644 is a versatile component designed to fit a variety of Cummins engines. This plug is engineered to ensure a secure and leak-proof connection, which is crucial for maintaining engine integrity and performance. Below is a detailed description of its compatibility with the specified engines:

QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, QSW73, QSZ90

The Threaded Plug 3336644 is compatible with the following engines:

- QSV81G

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

- QSZ90

These engines are part of Cummins’ range of industrial and power generation engines, known for their reliability and efficiency. The threaded plug fits seamlessly into these engines, providing a secure connection point for various applications, including fuel lines, coolant lines, and other fluid systems.

QSV91-G4 CM558/CM700 V102

The Threaded Plug 3336644 is also compatible with the QSV91-G4 CM558/CM700 V102 engine. This engine is a high-performance model, often used in demanding applications such as marine and heavy-duty industrial settings. The plug’s design ensures it can withstand the rigors of these environments, providing a reliable connection that is essential for the engine’s operation.

Installation and Usage

When installing the Threaded Plug 3336644, it is important to follow proper procedures to ensure a secure fit. This includes:

- Cleaning the Threaded Area: Ensure the area where the plug will be installed is free of debris and contaminants.

- Using the Correct Torque: Apply the recommended torque to avoid over-tightening, which can damage the threads, or under-tightening, which can lead to leaks.

- Inspecting for Damage: Before installation, inspect the plug for any damage that could affect its performance.

By adhering to these guidelines, the Threaded Plug 3336644 will provide a reliable and secure connection for the specified Cummins engines, ensuring optimal performance and longevity.

Role of Part 3336644 Threaded Plug in Various Engine Systems

The part 3336644 Threaded Plug is an integral component in several engine systems, ensuring the efficient operation and maintenance of the engine. Its applications span across multiple subsystems, each playing a distinct role in the overall functionality of the engine.

Air Intake and Cooling Systems

In the Air Intake system, the Threaded Plug is used to seal openings, preventing air leaks that could affect engine performance. Similarly, in the Coolant Heater Starting Arrangement, it ensures that the coolant system remains pressurized, which is essential for efficient heat transfer and engine starting in cold conditions.

Oil Systems

Within the Engine Oil Cooler and Engine Oil Assembly Cooler, the Threaded Plug helps maintain the integrity of the cooling circuits. By sealing off unnecessary passages, it ensures that oil flows correctly through the cooler, enhancing the engine’s lubrication and cooling efficiency. The Oil Assembly Cooler and Oil Cooler also benefit from this component, as it prevents contaminants from entering the system and maintains optimal oil pressure.

Turbocharger and Cylinder Block

In the Turbocharger system, the Threaded Plug is employed to seal various ports, ensuring that the turbocharger operates within specified parameters without leaks. In the Cylinder Block, it is used to plug unused coolant or oil passages, which helps in maintaining consistent temperatures and pressures throughout the engine block.

Fuel and Lubrication Systems

The Fuel Pump Assembly Cover utilizes the Threaded Plug to seal fuel lines and prevent leaks, ensuring a consistent fuel supply to the engine. In the Lubricating Oil Module Assembly, it plays a similar role, sealing oil passages to maintain lubrication efficiency and prevent oil loss.

Starting and Accessory Systems

For the Starting Motor and Front Gear Train Accessory, the Threaded Plug is crucial in sealing components that are not in use, thereby reducing the risk of mechanical failure and enhancing the reliability of the starting system. The Flywheel End Connect Assembly also employs this plug to ensure that the flywheel housing remains sealed, contributing to the smooth operation of the engine.

Thermostat and Water Systems

In the Thermostat Housing and Water Outlet Assembly Tube, the Threaded Plug ensures that the coolant system remains sealed, which is vital for maintaining engine temperature. The Water Transfer Assembly Tube also benefits from this component, as it ensures that coolant flows efficiently through the engine, preventing overheating.

Retrofit and Plumbing Systems

The Kit Retrofit Turbo Lub uses the Threaded Plug to seal old passages when retrofitting turbochargers, ensuring that the new system operates efficiently. In Plumbing Air Starter and Plumbing Flywheel Housing, it is used to seal various connections, preventing air or fluid leaks that could compromise engine performance.

Engine Monitoring and Assembly Systems

Finally, in the Engine Monitoring System and Engine Assembly Heater, the Threaded Plug is used to seal diagnostic ports and heating elements, respectively. This ensures that the monitoring system functions accurately and that the engine heating elements operate efficiently without leaks.

Overall, the part 3336644 Threaded Plug is a versatile component that enhances the reliability and efficiency of various engine systems by ensuring proper sealing and preventing leaks.

Conclusion

The Cummins 3336644 Threaded Plug is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its role in sealing various passages and preventing leaks contributes significantly to the overall performance of the engine and related systems. Proper installation, maintenance, and understanding of its applications are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.