This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

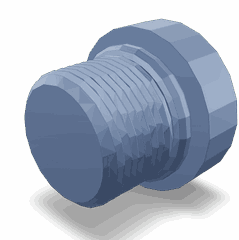

The Cummins 3337306 Threaded Plug is a component designed for use in commercial truck operations. Its primary role is to seal and plug specific openings within the truck’s systems, ensuring that fluids and gases remain contained within their designated pathways. A threaded plug, in general, is a fastener with threads that screw into a threaded hole to seal it. These plugs are commonly used in automotive components to prevent leaks, maintain pressure, and protect internal parts from contaminants 1.

Basic Concepts of Threaded Plugs

A threaded plug is a type of fastener that features external threads designed to mate with internal threads in a corresponding hole. Its function is to create a secure seal, preventing the escape of fluids or gases and blocking the entry of contaminants. In automotive systems, threaded plugs are vital for maintaining system integrity, ensuring that components operate within specified parameters without interference from external elements 2.

Purpose of the Cummins 3337306 Threaded Plug

The Cummins 3337306 Threaded Plug serves a specific role in truck operations by sealing openings in various systems, such as the engine, transmission, or hydraulic systems. By providing a reliable seal, it contributes to the overall functionality and efficiency of the truck’s systems, ensuring that fluids and gases remain within their intended pathways and pressures are maintained as designed.

Key Features

The Cummins 3337306 Threaded Plug is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding environments. The plug features a specific thread type that matches the threading in the application it is designed for, ensuring a secure fit. Additionally, its design specifications may include features such as a hex head for easy installation and removal using common tools.

Benefits

Using the Cummins 3337306 Threaded Plug offers several benefits. It provides improved system sealing, which is crucial for maintaining the integrity of the truck’s systems. Its durable construction ensures enhanced longevity, even under challenging operating conditions. Moreover, the reliable sealing it offers contributes to the overall reliability of the truck, reducing the likelihood of leaks or system failures.

Installation Process

Installing the Cummins 3337306 Threaded Plug requires careful attention to ensure a secure fit. The process involves cleaning the threaded hole to remove any debris or old sealant, applying a compatible sealant to the threads if necessary, and then screwing the plug into the hole until it is snug. It is important to use the appropriate tools to avoid cross-threading and to ensure the plug is tightened to the manufacturer’s specified torque settings to achieve the correct seal without over-tightening.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks or improper sealing, which can arise from incorrect installation, damage to the plug or threading, or degradation of the sealing material over time. Troubleshooting these issues involves inspecting the plug and threading for damage, ensuring the plug is correctly installed and tightened, and replacing the plug or sealant if necessary to restore the seal.

Maintenance Tips

Regular maintenance of the Cummins 3337306 Threaded Plug includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the plug and surrounding area can help prevent the buildup of contaminants that could affect its sealing capability. If signs of degradation are observed, or if the plug becomes difficult to remove or install, it may be time to consider replacement to ensure continued system integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on customer satisfaction underscore its position as a leader in providing reliable and efficient automotive components.

Threaded Plug 3337306 Compatibility with Cummins Engines

The threaded plug 3337306, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring compatibility and reliability across multiple models. This part is integral in sealing and securing various engine components, maintaining the engine’s integrity and performance.

Compatibility with Specific Models

-

ISBE CM800: The threaded plug 3337306 is engineered to fit seamlessly within the ISBE CM800 engine, providing a secure seal for critical engine components.

-

QSW/QSV82, QSW27, QSW36, QSW73, QSZ90: These engines also benefit from the use of the threaded plug 3337306. This part is specifically designed to meet the sealing requirements of these models, ensuring that the engine operates efficiently and reliably.

Grouping of Models

The threaded plug 3337306 is particularly notable for its compatibility with the QSW series engines, which includes the QSW27, QSW36, QSW73, and QSZ90 models. These engines share similar design characteristics and sealing requirements, making the threaded plug a versatile and essential component for these models.

By ensuring a precise fit and reliable seal, the threaded plug 3337306 contributes to the overall performance and longevity of these Cummins engines.

Role of Part 3337306 Threaded Plug in Engine Systems

The 3337306 Threaded Plug is utilized in various engine systems to ensure the integrity and functionality of these components. In the Accessory Drive Assembly Housing, it helps seal off unused ports, preventing fluid leaks and maintaining system pressure. Within the Air Intake Manifold, the threaded plug is employed to block off passages that are not in use, optimizing airflow and enhancing engine performance.

In the Front Gear Train Accessory, the threaded plug secures and seals critical areas, ensuring that the gear train operates smoothly without contamination from external elements. For the Fuel Filter Assembly and Fuel Assembly Filter, it plays a role in sealing connections and preventing fuel leaks, which is essential for maintaining fuel system efficiency and safety.

The Fuel Assembly Plumbing and Fuel Assembly Prefilter benefit from the threaded plug by ensuring that all connections are sealed properly, reducing the risk of fuel leaks and maintaining system pressure. In the Fuel Assembly Pump and Fuel Block Connection, it ensures that the pump operates in a sealed environment, enhancing its efficiency and reliability.

For the Fuel Sub-Assembly Plumbing, the threaded plug is critical in sealing various connections, ensuring that the fuel system remains pressurized and leak-free. In the Gear Assembly Housing and Housing, Pump Drive, it helps in sealing off areas that do not require fluid passage, thus maintaining the structural integrity of these housings.

In the Manifold, Air Intake, the threaded plug is used to block off unnecessary passages, allowing for better control of air intake and improved engine performance. The Oil Assembly Pan and Pan, Oil utilize the threaded plug to seal off areas within the pan, preventing oil leaks and ensuring that the oil system remains pressurized.

For the Plumbing, Fuel, it ensures that all fuel lines are properly sealed, reducing the risk of leaks and maintaining system efficiency. In the Power Take Off Assembly Gear and Power Take-Off Assembly Housing, the threaded plug seals off areas to prevent contamination and ensure smooth operation of the power take-off system.

Finally, in the Sea Water and Power Take-Off Assembly Housing and Sea Water Pump Housing, the threaded plug is essential for sealing connections and preventing sea water ingress, which could lead to corrosion and system failure.

Conclusion

The Cummins 3337306 Threaded Plug is a critical component in maintaining the integrity and efficiency of various systems within commercial trucks. Its role in sealing and securing engine components ensures that fluids and gases remain within their designated pathways, preventing leaks and maintaining system pressure. The plug’s durable construction and compatibility with a range of Cummins engines make it a reliable choice for ensuring the longevity and performance of truck systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.