This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

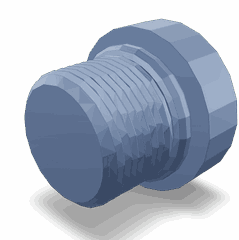

The Cummins Threaded Plug 3348110 is a specialized component designed for use in commercial truck maintenance. This plug serves a vital role in ensuring the integrity and efficiency of various truck systems. Its significance lies in its ability to provide reliable sealing and protection against leaks, contributing to the overall performance and longevity of the vehicle 2.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive and industrial applications. They function by creating a secure, leak-proof seal when screwed into place. These plugs are commonly employed in engine blocks, transmission systems, and hydraulic circuits to prevent fluid leakage and protect internal components from contaminants 1.

Purpose of the Cummins Threaded Plug 3348110

The Cummins Threaded Plug 3348110 is specifically designed to play a role in the operation of commercial trucks. It is utilized in various systems where sealing is required, such as in the engine block or transmission housing. By securely sealing openings, this plug helps maintain system pressure, prevent fluid leaks, and protect sensitive components from damage due to contamination or exposure to the environment 2.

Key Features

The 3348110 Threaded Plug boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a precise thread type that allows for a tight, secure fit within the designated opening. Additionally, its design specifications are tailored to meet the demanding requirements of commercial truck applications, providing reliable sealing under various operating conditions 3.

Benefits of Using the 3348110 Threaded Plug

Incorporating the 3348110 Threaded Plug into truck maintenance routines offers several advantages. Its superior sealing capabilities help maintain system integrity, reducing the risk of leaks and associated downtime. The plug’s durable construction ensures longevity, minimizing the need for frequent replacements. Furthermore, its reliable performance contributes to the overall efficiency and reliability of the truck, enhancing operational effectiveness 2.

Installation Process

Proper installation of the 3348110 Threaded Plug is crucial to ensure optimal performance and longevity. Begin by cleaning the installation site to remove any debris or contaminants. Carefully thread the plug into the designated opening, ensuring a snug fit without over-tightening. Use a torque wrench to achieve the recommended torque specification for secure installation. Finally, inspect the installation site to verify a leak-proof seal has been achieved 2.

Troubleshooting Common Issues

Common issues associated with threaded plugs may include leaks, difficulty in installation or removal, and damage to the plug or surrounding components. To address leaks, inspect the plug and installation site for signs of wear or damage. Ensure proper torque specifications are met during installation. If difficulty arises during installation or removal, use appropriate tools and techniques to avoid damaging the plug or threads. In cases of damage, replace the plug with a new one to maintain system integrity 2.

Maintenance Tips

Regular maintenance practices are essential to ensure the longevity and effectiveness of the 3348110 Threaded Plug. Inspect the plug and installation site during routine maintenance intervals for signs of wear, corrosion, or leaks. Replace the plug as needed to maintain a secure seal and prevent fluid leakage. Additionally, follow manufacturer recommendations for torque specifications and installation procedures to ensure optimal performance and longevity 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history spanning over a century, Cummins is committed to delivering innovative solutions that drive progress and improve lives worldwide. The company’s diverse product range includes engines for on-highway and off-highway applications, filtration systems, and power generation equipment. Cummins is renowned for its commitment to quality, reliability, and customer satisfaction, making it a trusted partner in the automotive industry 3.

Conclusion

In conclusion, the Cummins Threaded Plug 3348110 plays a crucial role in maintaining the integrity and efficiency of commercial truck systems. Its reliable sealing capabilities, durable construction, and precise design specifications make it an essential component for ensuring optimal performance and longevity in demanding truck applications. By incorporating this Cummins part into maintenance routines and following proper installation and maintenance practices, truck operators can enhance operational effectiveness and minimize downtime associated with leaks and system failures.

-

Alessandro Ferrari and Pietro Pizzo, Injection Technologies: Mixture Formation Strategies, SAE International, 2022.

↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ ↩ ↩ ↩ ↩ ↩ -

Konrad Reif Ed, Gasoline Engine Management Systems and Components, Springer Vieweg, 2015.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.