This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3348877 Threaded Insert is a specialized component designed for use in commercial truck applications. Its purpose is to provide a reliable and durable solution for securing various parts within the truck’s engine and other mechanical systems. The significance of this insert lies in its ability to enhance the structural integrity and operational efficiency of truck components, contributing to the overall performance and longevity of the vehicle 1.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to create or repair internal threads within materials that are difficult to thread, such as plastics, composites, or soft metals. They function by being inserted into a pre-drilled hole and secured in place, providing a durable and stable thread that can withstand repeated use and high loads. In automotive and mechanical engineering, threaded inserts are commonly used in applications where high strength, precision, and reliability are required 2.

Purpose of the Cummins 3348877 Threaded Insert

The Cummins 3348877 Threaded Insert plays a specific role in the operation and maintenance of commercial trucks. It is designed to reinforce and secure components within the truck’s engine and other mechanical systems. By providing a robust and reliable threading solution, this insert enhances the structural integrity of truck parts, ensuring they can withstand the rigors of heavy-duty use. Additionally, it facilitates easier repairs and maintenance by allowing for the secure attachment of bolts and other fasteners 3.

Key Features

The Cummins 3348877 Threaded Insert is characterized by several primary features that set it apart from other threaded inserts. It is composed of high-quality materials, ensuring durability and resistance to wear and corrosion. The design specifications of this insert include precise threading and a secure fit within the host material, providing a stable and reliable connection. Unique attributes may include specialized coatings or treatments that enhance its performance in demanding environments 4.

Benefits

The advantages provided by the Cummins 3348877 Threaded Insert are numerous. Its improved durability ensures long-lasting performance, even under heavy-duty conditions. The enhanced load-bearing capacity allows it to support significant weights and stresses, contributing to the overall reliability of the truck’s components. Additionally, the insert facilitates easier repairs and maintenance by providing a secure and stable threading solution, reducing the likelihood of fastener failure and component detachment 1.

Installation Process

Proper installation of the Cummins 3348877 Threaded Insert is crucial for ensuring optimal performance. The process involves several steps: first, the appropriate hole must be drilled into the host material using the correct size and depth. Next, the insert is inserted into the hole and secured in place, typically through expansion or adhesive bonding. Necessary tools include a drill, appropriate drill bits, and any specialized tools required for the specific insert type. Following manufacturer guidelines and best practices during installation will help ensure the insert functions as intended 2.

Troubleshooting and Maintenance

Common issues that may arise with threaded inserts include loosening, corrosion, and damage from excessive loads. Diagnostic methods for identifying problems may involve visual inspection, torque testing, and monitoring for signs of wear or failure. Maintenance tips to prolong the lifespan and efficiency of the Cummins 3348877 Threaded Insert include regular inspection for signs of wear, ensuring proper torque during fastening, and addressing any issues promptly to prevent further damage 3.

Compatibility and Applications

The Cummins 3348877 Threaded Insert is designed for use in various commercial truck models and systems, highlighting its versatility and widespread application. It is commonly used in engine components, transmission systems, and other critical areas where reliable threading solutions are required. Its compatibility with a range of materials and applications makes it a valuable component in the maintenance and repair of commercial trucks 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to excellence provide context for the quality and reliability of the 3348877 Threaded Insert, ensuring it meets the high standards required for heavy-duty applications 1.

Threaded Insert 3348877 Compatibility with Cummins Engines

The Cummins Threaded Insert part number 3348877 is designed to fit a variety of Cummins engines, providing a secure and reliable method for attaching components. This part is integral in ensuring the integrity and functionality of the engine assembly. Here is a detailed look at the compatibility of this threaded insert with various Cummins engines:

B5.9 Series Engines

- B5.9 G

- B5.9 GAS PLUS CM556

These engines, part of the B5.9 series, utilize the 3348877 threaded insert to secure various components, ensuring that parts remain firmly in place under operational stresses.

ISB Series Engines

- ISB CM550

The ISB CM550 engine incorporates the 3348877 threaded insert to maintain the structural integrity of its components, facilitating easy assembly and disassembly.

QSB5.9 Series Engines

- QSB5.9 30 CM550

- QSB5.9 CM850

Both the QSB5.9 30 CM550 and QSB5.9 CM850 engines utilize the 3348877 threaded insert to secure critical components, ensuring reliable performance and ease of maintenance.

QSB6.7 Series Engines

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB6.7 CM850 (CM2850)

The QSB6.7 series engines, including the CM2250, CM2350 B105, and CM850 (CM2850), all feature the 3348877 threaded insert. This part is crucial for maintaining the alignment and stability of various engine components, ensuring optimal performance and longevity.

QSB7 Series Engines

- QSB7 CM2880 B117

The QSB7 CM2880 B117 engine also incorporates the 3348877 threaded insert. This ensures that all components are securely fastened, contributing to the overall reliability and efficiency of the engine.

The threaded insert 3348877 is a vital component in the assembly and maintenance of these Cummins engines, providing a dependable method for securing parts and ensuring the engine operates smoothly 1.

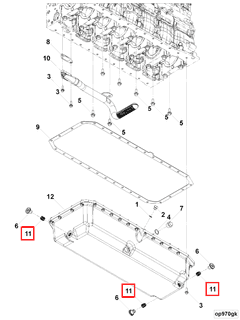

Role of Part 3348877 Threaded Insert in Engine Systems

The 3348877 Threaded Insert is an essential component in various engine systems, particularly in the assembly and maintenance of oil pans and oil pan kits. This threaded insert is designed to provide a secure and reliable connection point for bolts and fasteners, ensuring that the oil pan remains firmly attached to the engine block.

In the context of an oil pan, the 3348877 Threaded Insert is typically used to reinforce the mounting points where the oil pan connects to the engine. This is important because the oil pan houses a significant amount of the engine’s lubricant, and any failure in the mounting system could lead to oil leaks or even detachment of the oil pan. The threaded insert enhances the structural integrity of these connection points, distributing the load more evenly and reducing the risk of stripping or pulling out the fasteners 2.

When dealing with an oil pan kit, which often includes a new oil pan, gaskets, and other necessary components for replacement, the 3348877 Threaded Insert plays a similar role. It ensures that the new oil pan is securely fastened to the engine, providing a leak-proof seal and maintaining the structural stability of the oil pan during engine operation 3.

In summary, the 3348877 Threaded Insert is a key component in the reliable and efficient functioning of oil pans and oil pan kits. Its role in providing a strong, secure connection point for fasteners is indispensable for the overall performance and durability of the engine system 4.

Conclusion

The Cummins 3348877 Threaded Insert is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure durability, reliability, and ease of maintenance, making it an indispensable part in heavy-duty applications. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing the benefits of this threaded insert.

-

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ ↩ ↩ ↩ -

Robert Bosch GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ ↩ ↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ ↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.