This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

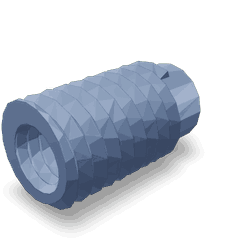

The Cummins 3376438 Threaded Insert is a component designed to enhance the maintenance and operation of heavy-duty trucks. Its role is significant in ensuring the longevity and reliability of truck components, particularly in environments where durability and performance are paramount.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to reinforce threaded holes in various materials. They function by providing a durable and reliable thread that can withstand repeated use and high stress. In mechanical and automotive engineering, threaded inserts are commonly used to repair damaged threads, enhance the strength of plastic or composite materials, and improve the overall integrity of assemblies 1.

Purpose of the Cummins 3376438 Threaded Insert

The Cummins 3376438 Threaded Insert is specifically designed to play a role in the structural integrity and functionality of heavy-duty truck components. By reinforcing threaded connections, it helps maintain the reliability of critical parts under demanding conditions. This insert ensures that connections remain secure, reducing the likelihood of failures due to wear or stress 2.

Key Features

The Cummins 3376438 Threaded Insert features a robust material composition, typically made from high-strength steel or other durable alloys. Its design specifications include precise threading and a secure fit within the host material. Unique attributes may include anti-corrosion coatings and specialized thread patterns that enhance grip and durability 3.

Benefits

Using the Cummins 3376438 Threaded Insert offers several advantages. It provides improved durability, ensuring that threaded connections remain intact even under heavy loads. The insert is designed for ease of installation, reducing downtime during maintenance. Additionally, it enhances performance in demanding conditions, contributing to the overall reliability of the truck.

Installation Process

Installing the Cummins 3376438 Threaded Insert involves several steps to ensure optimal performance. First, the existing thread must be cleaned and prepared. Using appropriate tools, the insert is then pressed into the threaded hole until it achieves a secure fit. Best practices include verifying the alignment and torque settings to ensure the insert is properly installed.

Troubleshooting Common Issues

Common problems with threaded inserts may include improper fit, corrosion, or damage from overuse. To address these issues, it is important to inspect the insert and surrounding components regularly. Solutions may involve cleaning the threads, reapplying anti-corrosion treatments, or replacing the insert if it shows signs of wear or failure.

Maintenance Tips

Regular maintenance of the Cummins 3376438 Threaded Insert is crucial for ensuring its longevity and reliable performance. This includes routine cleaning to remove dirt and debris, inspecting for signs of wear or corrosion, and replacing the insert if it becomes damaged. Adhering to these practices helps maintain the integrity of the threaded connections in heavy-duty trucks.

About Cummins

Cummins Inc. is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. The company offers a wide range of products known for their quality and reliability. Cummins components are trusted by professionals for their performance and durability, making them a preferred choice in the industry.

Role of Part 3376438 Threaded Insert in Engine Systems

The threaded insert, part number 3376438, is integral to the assembly and maintenance of various engine components. It provides a secure and reliable connection point for bolts, screws, and other fasteners, ensuring that components remain firmly in place under the high stress and vibration conditions typical of engine operation.

In the cylinder head assembly, the threaded insert is used to attach critical components such as the valve cover and intake manifold. This ensures a leak-proof seal and maintains the integrity of the combustion chamber. Additionally, it facilitates easy disassembly and reassembly during maintenance or repair procedures.

Within the engine block, the threaded insert secures components like the oil pan and timing cover. This not only ensures these parts are held firmly in place but also aids in maintaining the engine’s structural integrity. The insert’s design allows for repeated use without degradation, which is essential for long-term engine reliability.

For the transmission housing, the threaded insert plays a role in attaching the bell housing to the engine block. This connection is vital for transmitting power from the engine to the transmission smoothly and efficiently. The insert’s robust construction ensures that this connection remains stable under varying load conditions.

In fuel system components, such as the fuel rail and injector mounting brackets, the threaded insert provides a stable platform for mounting injectors. This ensures precise fuel delivery and helps maintain consistent engine performance. The insert’s corrosion-resistant properties are particularly beneficial in this application, given the exposure to fuel and other chemicals.

Overall, the threaded insert, part 3376438, enhances the durability and reliability of engine systems by providing a strong, secure connection point for a variety of components. Its versatile application across different engine parts underscores its importance in maintaining overall engine performance and longevity.

Conclusion

The Cummins 3376438 Threaded Insert is a vital component in the maintenance and operation of heavy-duty trucks. By reinforcing threaded connections, it ensures the reliability and longevity of critical truck components. Its robust design, ease of installation, and maintenance benefits make it an essential part in demanding environments. Regular maintenance and proper installation are key to maximizing the performance and durability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.