This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

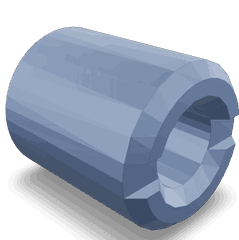

The Cummins 3376701 Threaded Insert is a critical component in commercial truck applications, designed to enhance vehicle integrity and performance by providing a reliable connection point for various truck components. This part ensures that the structural and mechanical systems of the truck operate efficiently and effectively.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to create strong, durable threads within materials that may not inherently support them, such as aluminum or plastic 1. They are embedded into a pre-drilled hole, providing a robust threading surface that can withstand significant stress and repeated use. In the automotive industry, threaded inserts are commonly employed to enhance the durability and reliability of connections between different parts, ensuring they remain secure under various operating conditions 2.

Purpose of the 3376701 Threaded Insert

The 3376701 Threaded Insert enhances structural integrity and facilitates repairs in truck operations. It is designed to be inserted into a pre-drilled hole in the truck’s frame or other components, providing a secure threading surface for bolts and other fasteners. This insert ensures that connections remain tight and reliable, even under the demanding conditions encountered in commercial trucking. Additionally, it simplifies the repair process by allowing for the easy replacement of damaged or worn components without requiring extensive modifications to the truck’s structure.

Key Features

The Cummins 3376701 Threaded Insert is characterized by its precise design and high-quality materials. It features specific dimensions and a thread type that ensures compatibility with standard fasteners used in truck manufacturing. The insert is typically made from materials that offer excellent corrosion resistance and durability, such as stainless steel or other high-strength alloys. These attributes contribute to its performance and longevity, making it a reliable component in commercial truck applications 3.

Benefits

The advantages provided by the 3376701 Threaded Insert include improved load distribution, enhanced repair capabilities, and increased longevity of truck components. By providing a strong, durable threading surface, it ensures that connections can withstand significant stress without loosening or failing. This results in more reliable performance and reduced maintenance requirements. Additionally, the insert’s design allows for straightforward installation and replacement, minimizing downtime and facilitating efficient repairs.

Installation Process

Proper installation of the 3376701 Threaded Insert involves several steps to ensure optimal performance. Begin by preparing the installation site, ensuring that the hole is clean, dry, and free of debris. Use the appropriate tools to insert the threaded insert into the pre-drilled hole, ensuring that it is seated correctly and securely. Follow manufacturer guidelines for torque specifications when tightening fasteners to the insert, to avoid over-tightening or under-tightening, which could compromise the connection’s integrity.

Troubleshooting Common Issues

Typical problems that may arise with threaded inserts include loosening or corrosion. To address these issues, regularly inspect the insert and surrounding components for signs of wear or damage. If corrosion is detected, clean the affected area thoroughly and apply a corrosion-resistant coating if necessary. Should the insert become loose, re-tighten the fasteners to the manufacturer’s specified torque, or replace the insert if it is damaged or worn.

Maintenance Tips

To ensure continued reliable performance of the 3376701 Threaded Insert, regular inspection and maintenance are recommended. Inspect the insert and surrounding components for signs of wear, corrosion, or damage during routine maintenance checks. Clean the area around the insert to remove any debris or contaminants that could affect its performance. Additionally, ensure that fasteners are tightened to the correct torque specifications to maintain a secure connection.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck and engine industry, known for its extensive product range and reputation for quality and reliability. Founded in 1919, Cummins has a long history of innovation and excellence in engine technology. The company offers a wide array of products, including engines, filtration systems, and aftermarket parts, designed to meet the demanding requirements of commercial trucking applications. Cummins’ commitment to quality and performance has established it as a trusted name in the industry.

Role of Part 3376701 Threaded Insert in Various Engine Systems

Diagnostic Kit

In the context of a diagnostic kit, the 3376701 Threaded Insert serves as a reliable connection point for various diagnostic tools and sensors. It ensures that these tools can be securely attached to the engine, providing accurate readings and data. This is particularly important during engine performance assessments and troubleshooting sessions, where precise measurements are essential.

Mounting Fixture

When integrated into a mounting fixture, the 3376701 Threaded Insert offers a stable and robust anchor point. This is vital for securely positioning the engine during maintenance or repair operations. The threaded insert’s design allows for easy attachment and detachment, facilitating efficient workflow and reducing the risk of damage to the engine or fixture.

Mounting Plate

On a mounting plate, the 3376701 Threaded Insert plays a key role in ensuring the engine is properly aligned and secured. It provides a consistent and strong connection, which is essential for maintaining the structural integrity of the engine assembly. This is particularly important in high-vibration environments where secure mounting is paramount to prevent engine misalignment or damage.

Thread Repair Insert Kit

Within a thread repair insert kit, the 3376701 Threaded Insert is used to restore damaged threads in engine components. It offers a durable and precise solution for repairing stripped or worn threads, ensuring that critical engine parts can be reattached securely. This application is essential for extending the lifespan of engine components and maintaining optimal performance.

Conclusion

The Cummins 3376701 Threaded Insert is a vital component in commercial truck applications, offering enhanced structural integrity, simplified repairs, and reliable performance. Its precise design, high-quality materials, and versatile applications make it an indispensable part in the maintenance and operation of commercial trucks. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.