This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

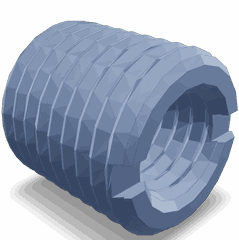

The Cummins 3376702 Threaded Insert is a specialized component designed for use in heavy-duty truck maintenance and operation. This insert plays a role in ensuring the structural integrity and functionality of various truck components. Understanding its purpose and significance is key to maintaining the performance and reliability of heavy-duty trucks.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to reinforce threaded holes in various materials. They function by providing a durable and reliable thread that can withstand repeated use and high stress. In mechanical and automotive engineering, threaded inserts are commonly employed to enhance the strength and longevity of components that require frequent disassembly and reassembly, or those subjected to significant mechanical stress 1.

Purpose of the 3376702 Threaded Insert

The 3376702 Threaded Insert is specifically designed to enhance the structural integrity and functionality of heavy-duty truck components. It plays a role in reinforcing threaded connections, which are critical in maintaining the assembly and operation of various truck parts. By providing a robust and reliable threading solution, this insert helps to prevent thread stripping and component failure, thereby contributing to the overall durability and performance of the truck 2.

Key Features

The 3376702 Threaded Insert boasts several key features that set it apart from other threaded inserts. It is constructed from high-strength materials, ensuring durability under demanding conditions. The design specifications of this insert include precise thread dimensions and a secure locking mechanism, which contribute to its reliable performance. Additionally, its unique attributes, such as corrosion resistance and ease of installation, make it a preferred choice for heavy-duty applications 3.

Benefits

Using the 3376702 Threaded Insert offers several advantages. Its improved durability ensures long-lasting performance even under harsh operating conditions. The ease of installation simplifies maintenance procedures, reducing downtime. Furthermore, its enhanced performance in demanding environments contributes to the overall efficiency and reliability of heavy-duty trucks.

Installation Process

Proper installation of the 3376702 Threaded Insert is crucial for optimal performance and longevity. The process involves several steps, including preparing the installation site, using the appropriate tools, and following best practices to ensure a secure fit. Detailed instructions and guidelines are provided to facilitate a smooth and effective installation.

Common Applications

The 3376702 Threaded Insert is commonly used in various applications within heavy-duty trucks. It is typically employed in components or systems where reliable and durable threaded connections are required. Specific applications may include engine components, transmission systems, and chassis parts, among others.

Troubleshooting and Maintenance

To ensure the continued reliable performance of the 3376702 Threaded Insert, it is important to be aware of common issues such as wear and tear or improper installation. Regular maintenance practices, including inspection and replacement when necessary, can help prolong the lifespan of the insert and prevent potential failures.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a strong reputation for producing reliable and high-performance components. The company’s dedication to excellence is reflected in its manufacturing processes and the durability of its products.

Role of Part 3376702 Threaded Insert in Engine Systems

The 3376702 Threaded Insert is an essential component in the maintenance and repair of engine systems. It is specifically designed to be used with thread repair insert kits, which are vital for restoring the integrity of damaged or worn threads within an engine.

When an engine’s threaded components, such as cylinder heads, engine blocks, or oil galleries, suffer from thread damage due to wear, corrosion, or improper installation, the functionality and safety of the engine can be compromised. The 3376702 Threaded Insert addresses this issue by providing a robust and durable replacement for the damaged threads.

In the context of a thread repair insert kit, the 3376702 Threaded Insert is installed into the damaged thread using specialized tools. This process involves cleaning and preparing the damaged area, followed by the precise insertion of the threaded insert. Once installed, the insert creates a new, reliable thread that can withstand the high stresses and temperatures encountered in engine operation.

The use of the 3376702 Threaded Insert ensures that critical engine components, such as fasteners for cylinder heads, valve covers, and oil pans, can be securely fastened. This, in turn, maintains the structural integrity of the engine and prevents leaks, which are common issues when threads are compromised.

Additionally, the 3376702 Threaded Insert plays a significant role in the longevity and performance of engine systems. By providing a strong and consistent thread, it allows for proper torque application during assembly, which is essential for the even distribution of clamping force. This is particularly important in high-performance engines where precise torque settings are required to optimize engine efficiency and power output.

Conclusion

In summary, the 3376702 Threaded Insert is a key component in the maintenance and repair of engine systems, ensuring that threaded connections remain secure, reliable, and capable of withstanding the demanding conditions of engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.