This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

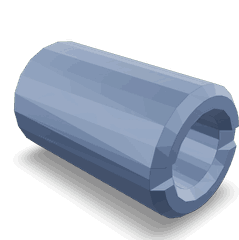

The Cummins 3376704 Threaded Insert is a specialized component designed for use in commercial truck maintenance and operation. This insert enhances the durability and functionality of truck components by providing a secure and reliable threading solution. Its significance lies in its ability to improve the structural integrity of parts that are subject to high stress and frequent use 1.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to create or repair internal threads within various materials. They function by being inserted into a pre-drilled hole, providing a durable and precise threading that can withstand significant mechanical stress. In automotive and mechanical contexts, threaded inserts are commonly used to reinforce connections, facilitate easy assembly and disassembly, and ensure consistent thread quality 2.

Purpose of the Cummins 3376704 Threaded Insert

The Cummins 3376704 Threaded Insert is specifically designed to enhance the operation and maintenance of commercial trucks. It plays a role in the structural integrity and functionality of truck components by providing a robust threading solution that can endure the demanding conditions of commercial truck use. This insert ensures that connections remain secure, reducing the risk of component failure and enhancing overall truck performance 3.

Key Features

The Cummins 3376704 Threaded Insert features a high-quality material composition, typically consisting of durable metals such as steel or brass, ensuring longevity and resistance to wear. Its design specifications include precise threading and a secure fit within the host material, which distinguishes it from other threaded inserts. Additionally, it may possess unique attributes such as corrosion resistance or enhanced load-bearing capabilities.

Benefits of Using the Cummins 3376704 Threaded Insert

Utilizing the Cummins 3376704 Threaded Insert offers several advantages. These include improved durability of the threaded connections, enhanced performance under stress, and potential cost savings over time due to reduced need for repairs and replacements. The insert’s reliable performance contributes to the overall efficiency and longevity of commercial truck components.

Installation Process

Proper installation of the Cummins 3376704 Threaded Insert involves several steps to ensure optimal performance. First, the appropriate hole size must be drilled into the component. The insert is then inserted using a specialized tool that ensures it is seated correctly and securely. Following installation, it is important to verify that the threading is accurate and that the insert is firmly in place to prevent any issues during operation.

Troubleshooting Common Issues

Common problems with threaded inserts may include loose connections, damage to the insert, or difficulties during installation. To address these issues, it is important to ensure that the correct hole size is used, the insert is properly seated, and that all tools and equipment are in good condition. Regular inspections and maintenance can help prevent these problems, ensuring the longevity and reliability of the insert.

Maintenance Recommendations

Regular maintenance of the Cummins 3376704 Threaded Insert is crucial for ensuring its longevity and reliable performance. This includes periodic inspections to check for signs of wear or damage, ensuring that connections remain secure, and replacing the insert if necessary. Adhering to recommended inspection schedules and replacement criteria will help maintain the insert’s effectiveness.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer with a rich history in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, known for their quality and innovation. Cummins is committed to providing reliable and high-performance components that meet the demanding needs of commercial truck operators, ensuring efficiency and durability in their fleets.

Role of Part 3376704 Threaded Insert in Engine Systems

The part 3376704 Threaded Insert is an essential component in maintaining the integrity and functionality of various engine systems. It is specifically designed to reinforce and repair threaded holes within engine components, ensuring secure and reliable connections.

Application in Thread Repair Insert Kits

When dealing with a Thread Repair Insert Kit, the 3376704 Threaded Insert plays a significant role. It is used to restore damaged threads in engine blocks, cylinder heads, and other critical components. By providing a new, precision-machined thread, it allows for the re-installation of fasteners such as bolts and screws with the required torque specifications. This ensures that all connections remain tight and secure, preventing leaks and component failure.

Integration with Engine Components

In engine systems, the 3376704 Threaded Insert is often employed in the following scenarios:

-

Cylinder Head Repair: When cylinder head bolts strip or damage the threads, the insert is installed to maintain the structural integrity of the head and ensure proper sealing against the engine block.

-

Engine Block Reinforcement: For engines that experience wear or damage to the threads in the block, the insert provides a durable solution that can withstand high torque and thermal cycles.

-

Ancillary Component Mounting: Various sensors, brackets, and other ancillary components require secure mounting. The threaded insert ensures that these parts are firmly attached, contributing to the overall reliability of the engine system.

Benefits in Maintenance and Repair

The use of the 3376704 Threaded Insert in engine maintenance and repair offers several advantages:

-

Enhanced Durability: The insert is typically made from high-strength materials, providing greater resistance to wear and tear compared to standard threads.

-

Simplified Repair Process: Installing a threaded insert is a straightforward process that can be performed with standard tools, reducing downtime and repair costs.

-

Consistent Performance: By ensuring that all threaded connections meet the original equipment manufacturer (OEM) specifications, the insert helps maintain consistent engine performance and reliability.

Conclusion

The Cummins 3376704 Threaded Insert is a vital component in the maintenance and repair of engine systems, offering enhanced durability, simplified repair processes, and consistent performance. Its role in reinforcing and repairing threaded holes within engine components ensures secure and reliable connections, contributing to the overall efficiency and longevity of commercial truck components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.