This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

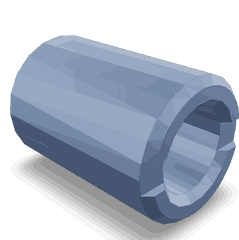

The Cummins 3376710 Threaded Insert is a specialized component designed for use in commercial trucks. Its primary role is to enhance the durability and reliability of threaded connections within the truck’s engine and other systems. By providing a robust and secure fitting, this insert helps maintain the integrity of critical components, ensuring smooth and efficient operation of the vehicle 1.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical fasteners used to reinforce or repair threaded holes in various materials. They are commonly made from metal and are designed to be inserted into pre-drilled holes, providing a strong and durable thread that can withstand high levels of stress and repeated use. In mechanical applications, threaded inserts play a vital role in ensuring that connections remain secure and reliable over time 2.

Purpose of the Cummins 3376710 Threaded Insert

The Cummins 3376710 Threaded Insert serves a specific function within the operation of a truck. It is typically used in the engine or other systems where secure and durable threaded connections are required. By providing a reinforced thread, this insert helps prevent issues such as stripping or loosening, which can lead to mechanical failures. Its role is to ensure that critical components remain firmly attached, contributing to the overall reliability and performance of the truck 3.

Key Features

The Cummins 3376710 Threaded Insert boasts several primary characteristics that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design of the insert allows for easy installation, while its unique properties provide superior thread strength. These features make it an ideal choice for applications where reliability and longevity are paramount.

Benefits

Using the Cummins 3376710 Threaded Insert offers several advantages. One of the main benefits is improved durability, as the insert provides a stronger and more reliable thread compared to standard fasteners. Additionally, the ease of installation reduces downtime and labor costs. Over time, the enhanced performance and longevity of the insert can lead to potential cost savings, making it a valuable component for commercial truck maintenance.

Installation Process

Installing the Cummins 3376710 Threaded Insert requires following a precise procedure to ensure optimal performance. Begin by cleaning the threaded hole to remove any debris or contaminants. Next, insert the threaded insert into the hole, ensuring it is aligned correctly. Use the appropriate tool to secure the insert in place, following manufacturer guidelines for torque specifications. It is important to avoid over-tightening, which can damage the insert or surrounding material.

Troubleshooting and Maintenance

To identify common issues related to threaded inserts, regularly inspect the connections for signs of wear or damage. Maintenance practices such as periodic tightening and lubrication can help ensure longevity. If an insert shows signs of significant wear or failure, it should be replaced promptly to prevent further mechanical issues. Proper care and attention to threaded inserts can contribute to the overall reliability of the truck.

Compatibility and Usage

The Cummins 3376710 Threaded Insert is designed for use in specific types of trucks and engine models. It is commonly employed in applications where durable and secure threaded connections are required. For detailed compatibility information and specific application notes, refer to the manufacturer’s guidelines or consult with a qualified technician.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company offers a comprehensive product range, including engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial transportation. Cummins’ commitment to innovation and quality has earned it a strong reputation among fleet operators and maintenance professionals.

Role of Part 3376710 Threaded Insert in Engine Systems

The part 3376710 Threaded Insert is an essential component in maintaining the integrity and functionality of various engine systems. It is specifically designed to facilitate secure and reliable connections within the engine’s architecture.

Integration with Thread Repair Insert Kit

When utilized in conjunction with a Thread Repair Insert Kit, the 3376710 Threaded Insert plays a significant role in repairing and reinforcing threaded connections. This is particularly important in scenarios where existing threads have become damaged or worn, which can lead to leaks or insufficient fastening. The insert ensures that the repaired threads maintain their structural integrity and can withstand the operational stresses of the engine.

Application in Fuel System Components

In fuel system components, the 3376710 Threaded Insert is used to secure fuel lines and fittings. This is vital for maintaining a sealed and efficient fuel delivery system. The insert helps prevent fuel leaks, which are not only hazardous but can also lead to inefficient engine performance. By providing a robust connection point, the insert ensures that fuel lines remain securely attached under varying pressure conditions.

Use in Exhaust System Connections

Within the exhaust system, the 3376710 Threaded Insert is employed to connect exhaust manifolds and pipes. This application is important for ensuring that the exhaust gases are directed away from the engine compartment efficiently. The insert helps maintain a tight seal, preventing exhaust leaks that could lead to increased emissions and reduced engine performance. Additionally, it withstands the high temperatures and corrosive environments typical of exhaust systems.

Role in Cooling System Components

In cooling system components, such as radiator hoses and thermostat housings, the 3376710 Threaded Insert is used to create secure connections. This is essential for maintaining the integrity of the cooling system, ensuring that coolant flows smoothly without leaks. The insert contributes to the overall reliability of the cooling system, helping to prevent overheating and potential engine damage.

Application in Intake System Fittings

For intake system fittings, the 3376710 Threaded Insert is crucial in securing air intake hoses and sensors. This ensures that the air intake system remains sealed, allowing for optimal airflow into the engine. The insert helps maintain the efficiency of the intake system, contributing to better engine performance and fuel economy.

Use in Oil System Connections

In the oil system, the 3376710 Threaded Insert is used to connect oil lines and filters. This application is vital for maintaining the lubrication system’s integrity, ensuring that oil is delivered efficiently to all moving parts. The insert helps prevent oil leaks, which can lead to insufficient lubrication and potential engine wear.

Conclusion

By integrating the 3376710 Threaded Insert into these various engine systems, mechanics and engineers can ensure that connections remain secure, efficient, and reliable, contributing to the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.