This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

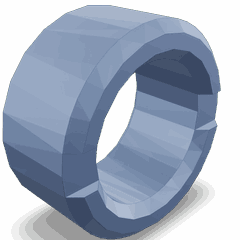

The Cummins 3376712 Threaded Insert is a component designed for use in commercial trucks. It serves to maintain vehicle integrity and performance by providing a reliable fastening solution in various truck components. Its role is significant in ensuring that parts remain securely attached, contributing to the overall durability and operational efficiency of the vehicle 1.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical fasteners used to create or repair internal screw threads within materials that may not hold threads well on their own, such as aluminum or plastic. They function by being inserted into a pre-drilled hole and then secured in place, providing a durable and reliable thread for screws or bolts. In the automotive industry, threaded inserts are commonly used to enhance the strength and longevity of fastening points, especially in areas subjected to high stress or frequent disassembly and reassembly 2.

Purpose of the 3376712 Threaded Insert

The 3376712 Threaded Insert plays a specific role in the operation of a truck by enhancing structural integrity and facilitating repairs. It is designed to be installed in areas where the native material may not support a screw or bolt adequately. By providing a robust threading option, it ensures that components remain securely fastened, which is vital for the safe and efficient operation of the vehicle. Additionally, it simplifies the repair process by offering a reliable solution for re-threading damaged or worn-out holes 3.

Key Features

The Cummins 3376712 Threaded Insert boasts several key features that contribute to its effectiveness and durability. These include a material composition that is resistant to corrosion and wear, a thread size that matches common fasteners used in truck maintenance, and design specifications that ensure a secure fit within the host material. These features collectively enhance the insert’s ability to withstand the rigors of commercial truck operation.

Benefits

The advantages provided by the 3376712 Threaded Insert include improved load distribution across fastening points, enhanced fastening security to prevent loosening under vibration or stress, and longevity even in harsh operating conditions. These benefits contribute to the overall reliability and performance of the truck, reducing the likelihood of component failure and the need for frequent repairs.

Installation Process

Proper installation of the 3376712 Threaded Insert involves several steps to ensure it functions correctly. First, the appropriate hole size must be drilled into the material. The insert is then inserted into the hole and secured using a specified method, such as pressing or threading, depending on the insert’s design. Best practices include ensuring the hole is clean and free of debris before insertion and using the correct tools to avoid damaging the insert or the surrounding material. Potential pitfalls to avoid include over-tightening, which can damage the insert, and insufficient hole preparation, which can lead to a loose fit.

Troubleshooting Common Issues

Common problems associated with threaded inserts, such as loosening or corrosion, can often be addressed through proper maintenance and care. Loosening may be mitigated by ensuring the insert is correctly sized and installed, while corrosion can be prevented by selecting inserts made from corrosion-resistant materials and applying protective coatings where appropriate. Regular inspections can help identify issues early, allowing for timely repairs or replacements.

Maintenance Tips

To ensure the longevity and optimal performance of the 3376712 Threaded Insert, regular maintenance checks are recommended. This includes inspecting the insert for signs of wear, corrosion, or loosening and ensuring that fasteners are tightened to the manufacturer’s specifications. Additionally, keeping the area around the insert clean and free of debris can prevent contamination that may lead to premature failure.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes components and systems designed to enhance the performance, efficiency, and durability of commercial vehicles, reflecting its commitment to innovation and customer satisfaction.

Role of Part 3376712 Threaded Insert in Component Systems

The Part 3376712 Threaded Insert is an essential component in various engine systems, providing robust and reliable thread repair solutions. When integrated into a Thread Repair Insert Kit, this part ensures the longevity and functionality of engine components by addressing common issues such as stripped or damaged threads.

In the context of engine maintenance and repair, the Threaded Insert plays a significant role in the following ways:

-

Cylinder Head Repair: When cylinder heads suffer from damaged threads, the Part 3376712 Threaded Insert is used to restore the integrity of the threads. This ensures that bolts and fasteners can be securely tightened, preventing leaks and maintaining the structural integrity of the cylinder head.

-

Block Repair: Engine blocks often encounter thread damage due to wear and tear or improper installation of fasteners. The Threaded Insert is employed to repair these threads, allowing for the secure attachment of components such as oil pans, valve covers, and other critical engine parts.

-

Intake Manifold Repair: Intake manifolds can develop thread issues over time, leading to potential leaks and reduced engine performance. The use of the Threaded Insert in a repair kit helps to reinforce these threads, ensuring a tight seal and efficient operation of the intake system.

-

Exhaust Manifold Repair: Similar to intake manifolds, exhaust manifolds may also suffer from thread damage. The Threaded Insert is vital in repairing these threads, facilitating the secure attachment of exhaust components and maintaining the integrity of the exhaust system.

-

General Fastener Repair: Beyond specific engine components, the Threaded Insert is widely used in general fastener repair across various engine systems. It provides a reliable solution for restoring threads in bolts, nuts, and other fasteners, ensuring they can withstand the stresses of engine operation.

By incorporating the Part 3376712 Threaded Insert into thread repair procedures, engineers and mechanics can enhance the durability and performance of engine components, ultimately contributing to the overall reliability of the engine system.

Conclusion

The Cummins 3376712 Threaded Insert is a vital component in the maintenance and repair of commercial truck engines. Its design and features ensure reliable fastening solutions, enhancing the durability and performance of various engine components. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, contributing to the overall efficiency and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.