This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3393655 Threaded Insert is a specialized component designed for use in commercial truck maintenance and operation. It serves a pivotal role in enhancing the durability and functionality of truck components, ensuring reliable performance under demanding conditions.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical components used to reinforce or repair threaded holes in various materials. They function by providing a durable and reliable thread that can withstand high stress and repeated use. In automotive and mechanical contexts, threaded inserts are commonly employed to restore or enhance the integrity of threaded connections, ensuring secure fastening and prolonged component life 1.

Purpose of the Cummins 3393655 Threaded Insert

The Cummins 3393655 Threaded Insert is specifically designed to improve the functionality and durability of truck components. It plays a role in reinforcing threaded connections, which are subject to significant stress and wear in commercial truck applications. By providing a robust and reliable thread, this insert helps maintain the integrity of critical connections, contributing to the overall performance and longevity of the truck 2.

Key Features

The Cummins 3393655 Threaded Insert boasts several primary features that distinguish it from other threaded inserts. It is composed of high-strength materials, ensuring durability under demanding conditions. The design specifications of this insert include precise threading and a robust construction, which facilitate easy installation and secure fastening. Additionally, unique attributes such as corrosion resistance and high load-bearing capacity further enhance its performance in commercial truck applications.

Benefits of Using the Cummins 3393655 Threaded Insert

Utilizing the Cummins 3393655 Threaded Insert offers several advantages. It provides improved strength and durability compared to traditional fastening methods, ensuring reliable performance in high-stress environments. The ease of installation is another significant benefit, as the insert can be quickly and securely fitted into place, reducing downtime during maintenance procedures. Furthermore, the enhanced thread integrity contributes to the longevity of truck components, ultimately leading to cost savings and improved operational efficiency 3.

Installation Process

Proper installation of the Cummins 3393655 Threaded Insert involves several steps to ensure a secure fit. Begin by preparing the threaded hole, ensuring it is clean and free of debris. Use the appropriate tools to insert the threaded insert into the hole, applying even pressure to achieve a snug fit. Verify the installation by checking for proper alignment and thread engagement. Following these steps will help ensure the insert is securely fastened and ready for use.

Common Applications

The Cummins 3393655 Threaded Insert is commonly used in various applications within the commercial truck industry. It is frequently employed in components such as engine blocks, transmission housings, and chassis parts, where reliable threaded connections are crucial. Specific systems where this insert is commonly used include fuel injection systems, brake components, and suspension systems, all of which benefit from the enhanced durability and strength provided by the insert.

Troubleshooting and Maintenance

To ensure optimal performance and longevity of the Cummins 3393655 Threaded Insert, regular maintenance and troubleshooting are recommended. Inspect the insert for signs of wear or damage, and replace it if necessary to prevent failure. Additionally, ensure that all threaded connections are properly torqued to the manufacturer’s specifications to maintain secure fastening. Addressing common issues promptly, such as corrosion or loose connections, will help extend the life of the insert and the components it supports.

Manufacturer Information - Cummins

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. The company is committed to quality and innovation, producing a wide range of components designed to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence is evident in their rigorous testing and quality control processes, ensuring that their products meet the highest standards of durability and functionality.

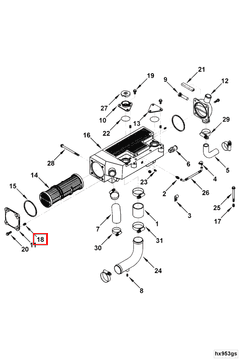

Role of Part 3393655 Threaded Insert in Engine Systems

The part 3393655 Threaded Insert is instrumental in ensuring the secure and efficient assembly of various engine components. In the context of an aftercooler system, this threaded insert facilitates the robust connection between the aftercooler and its housing. It allows for the precise alignment and fastening of these components, which is essential for optimal cooling performance and durability.

In the arrangement of a turbocharger system, the threaded insert plays a significant role in connecting the turbocharger to the heat exchanger. This connection is vital for maintaining the integrity of the system, ensuring that the compressed air is effectively cooled before entering the engine. The threaded insert’s design enables a leak-proof seal, which is necessary for the efficient operation of the turbocharger.

Furthermore, within the heat exchanger assembly, the threaded insert is used to join the heat exchanger to its housing. This connection is fundamental for the proper functioning of the heat exchanger, as it ensures that the transfer of heat between the fluids is conducted efficiently and without loss. The threaded insert’s presence in this application contributes to the overall reliability and performance of the heat exchanger system.

Conclusion

The Cummins 3393655 Threaded Insert is a critical component in the maintenance and operation of commercial trucks. Its design and features enhance the durability and functionality of truck components, ensuring reliable performance under demanding conditions. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.