This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

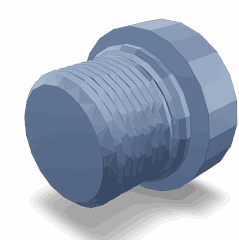

The Cummins 3417076 Threaded Plug is a component used in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is vital for maintaining the truck’s performance and longevity.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components designed to seal openings in various systems. They are commonly used in automotive and industrial applications to prevent fluid or gas leakage, protect against contaminants, and maintain system integrity. Threaded plugs are characterized by their screw-like threads, which allow them to be securely fastened into corresponding threaded holes 1.

Purpose of the Cummins 3417076 Threaded Plug

The Cummins 3417076 Threaded Plug plays a role in sealing specific openings within a truck’s engine or other systems. Its primary function is to ensure that fluids or gases remain contained within their designated pathways, preventing leaks that could lead to system failure or reduced efficiency. By maintaining proper sealing, the plug contributes to the overall performance and reliability of the truck 2.

Key Features

The Cummins 3417076 Threaded Plug is designed with several key features that enhance its performance and durability. It is typically made from high-quality materials that offer resistance to corrosion and wear. The plug features a specific thread type that ensures a secure fit within the corresponding threaded hole. Additionally, its design specifications are tailored to meet the demanding requirements of commercial truck applications.

Benefits of Using the Cummins 3417076 Threaded Plug

Using the Cummins 3417076 Threaded Plug provides several advantages. It offers improved sealing capabilities, which help maintain system integrity and prevent leaks. The plug’s resistance to corrosion ensures longevity, even in harsh operating environments. Additionally, its design allows for ease of installation, reducing downtime during maintenance procedures.

Installation Process

Proper installation of the Cummins 3417076 Threaded Plug involves several steps. First, ensure that the threaded hole is clean and free of debris. Using the appropriate tools, carefully screw the plug into the hole until it is securely fastened. It is important to avoid over-tightening, as this can damage the threads or the plug itself. Once installed, verify that the plug is properly sealed and there are no signs of leakage.

Common Issues and Troubleshooting

Common issues associated with threaded plugs include leaks and damage to the plug or the threaded hole. If a leak is detected, the plug should be removed and inspected for damage. If the plug is intact, the threaded hole may need to be cleaned or repaired. In cases where the plug is damaged, it should be replaced with a new one to ensure proper sealing.

Maintenance Tips

Regular maintenance of the Cummins 3417076 Threaded Plug is important for ensuring its longevity and optimal performance. Inspect the plug during routine maintenance checks for signs of wear or damage. Clean the plug and the surrounding area to remove any contaminants that could affect its sealing capabilities. Following these maintenance tips will help prevent issues and ensure the plug continues to function effectively.

Manufacturer Information - Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. The company has a long history of innovation and excellence, offering a wide range of products designed to meet the needs of commercial truck operators. Cummins components, including the 3417076 Threaded Plug, are engineered to deliver reliable performance and durability in demanding applications 3.

Compatibility with Cummins Engines

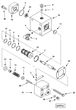

The Cummins-manufactured Threaded Plug part number 3417076 is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. Here is an overview of the engines with which this part is compatible:

Cummins K-Series Engines

- K19

- K38

- K50

The Threaded Plug 3417076 is engineered to seamlessly integrate with the K-Series engines, providing a reliable seal and ensuring the engine’s operational integrity.

Cummins M11 Engines

- M11 CELECT PLUS

- M11 MECHANICAL

This threaded plug is also compatible with the M11 engines, both the CELECT PLUS and MECHANICAL variants. It is designed to fit precisely, ensuring optimal performance and longevity.

Cummins N14 Engine

- N14 MECHANICAL

The N14 MECHANICAL engine is another model that benefits from the use of the Threaded Plug 3417076. This part is crafted to fit perfectly, maintaining the engine’s efficiency and reliability.

Cummins NH/NT 855 Engine

- NH/NT 855

The NH/NT 855 engine is also included in the list of compatible engines for the Threaded Plug 3417076. This part is designed to ensure a secure fit, contributing to the overall performance of the engine.

Cummins 6B5.9 Engine

- 6B5.9

Lastly, the 6B5.9 engine is another model that can utilize the Threaded Plug 3417076. This part is engineered to provide a precise fit, ensuring the engine operates smoothly and efficiently.

Role of the Cummins 3417076 Threaded Plug in Engine Systems

The Cummins 3417076 Threaded Plug is an essential component in various engine systems, facilitating the secure and efficient operation of several critical assemblies.

In aftercooler plumbing, the threaded plug ensures that connections are sealed properly, preventing coolant leaks and maintaining optimal cooling efficiency for the compressed air.

For base parts, it provides a reliable sealing solution where different components interface, ensuring no fluid or gas escapes, which is vital for the integrity of the engine’s foundational structure.

In the camshaft and camshaft and gear systems, the threaded plug is used to seal off passages or bolt holes, ensuring that the camshaft operates within a sealed environment, which is necessary for precise valve timing and engine performance.

The check valve system utilizes the threaded plug to maintain unidirectional flow, preventing backflow which could lead to inefficient engine operation.

Within the connecting rod and piston assembly, the threaded plug may be employed to seal oil passages, ensuring that lubrication is directed correctly to reduce friction and wear.

In the cylinder head and cylinder head mounting, the threaded plug plays a role in sealing coolant or oil passages, which is essential for thermal management and lubrication of the cylinder head components.

For EBM (Engine Build Module): Performance Parts and EBM: Device, the threaded plug is critical in sealing high-pressure passages, contributing to the enhanced performance characteristics of these specialized components.

In timing control systems, the threaded plug ensures that timing passages are sealed, which is important for the accurate delivery of timing fluids or gases that control valve operation.

The fuel connection and injector plumbing systems rely on the threaded plug to maintain fuel integrity by sealing connections, which is fundamental for consistent fuel delivery and combustion.

When dealing with oil connections, the threaded plug is used to seal oil lines and passages, ensuring that oil pressure is maintained for lubrication purposes.

In the complex oil control (top level assembly) valve, oil control top level assembly valve, and oil control valve valve systems, the threaded plug is instrumental in sealing various oil passages, which is crucial for the modulation of oil flow to different engine components.

The oil manifold system uses the threaded plug to seal off individual oil passages, ensuring that oil is distributed correctly throughout the engine.

In performance parts, the threaded plug is often used to seal custom passages or bolt holes, enhancing the performance and reliability of aftermarket components.

Lastly, in systems like the step oil control top level assembly valve and the step white smoke kit, the threaded plug is used to seal passages that are specific to these performance-enhancing or diagnostic kits, ensuring they function as intended.

Overall, the Cummins 3417076 Threaded Plug is a versatile component that contributes to the sealing and operational integrity of a wide range of engine systems.

Conclusion

The Cummins 3417076 Threaded Plug is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its role in sealing various engine systems ensures that fluids and gases remain contained, preventing leaks and maintaining system integrity. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engines are essential for maximizing the performance and longevity of this part.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.