This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

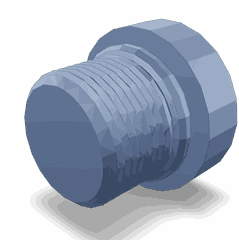

The Cummins 3423281 Threaded Plug is a critical component in commercial trucks, ensuring the integrity and efficiency of various systems within the vehicle. Its role is vital in maintaining the operational standards of trucks, especially in environments where durability and reliability are essential 1.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, preventing the escape of fluids or gases and keeping contaminants out. They are commonly employed in automotive and industrial applications to maintain system pressure, protect against environmental factors, and ensure the smooth operation of machinery. These plugs are typically made from durable materials and are designed to withstand high pressures and temperatures 2.

Purpose of the Cummins 3423281 Threaded Plug

The Cummins 3423281 Threaded Plug serves a specific function within the truck’s systems, primarily by sealing openings in the engine or other critical areas. This plug helps maintain system pressure, prevent leaks, and protect internal components from external contaminants. Its precise design ensures a secure fit, contributing to the overall efficiency and reliability of the truck’s operation 3.

Key Features

The Cummins 3423281 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for strength and resistance to corrosion, and its thread type, which ensures a tight and secure seal. The design specifications of this plug are tailored to meet the demanding conditions of commercial truck applications, providing long-lasting service and reliability.

Benefits

Utilizing the Cummins 3423281 Threaded Plug offers several advantages. It contributes to improved system integrity by effectively sealing openings and preventing leaks. This plug also enhances the performance of the truck’s systems by maintaining optimal pressure levels and protecting components from damage. Additionally, its durable construction supports the longevity of the truck’s components, reducing the need for frequent replacements.

Installation Process

Proper installation of the Cummins 3423281 Threaded Plug is vital for ensuring optimal performance and safety. The process involves cleaning the installation site to remove any debris, applying a compatible sealant to the threads if necessary, and screwing the plug into place until it reaches the specified torque. Careful attention to these steps ensures a secure fit and prevents potential issues down the line.

Common Issues and Troubleshooting

Threaded plugs, including the Cummins 3423281, may encounter issues such as leaks or difficulty in removal. Diagnosing these problems involves inspecting the plug and its seating for signs of damage or wear. Troubleshooting steps may include re-torquing the plug, replacing damaged components, or using specialized tools for removal if necessary. Addressing these issues promptly helps maintain the efficiency and safety of the truck’s systems.

Maintenance Tips

Regular maintenance of the Cummins 3423281 Threaded Plug is important for prolonging its life and ensuring continued system integrity. This includes periodic inspection for signs of wear or damage, cleaning the plug and its seating area, and replacing the plug according to the manufacturer’s guidelines or when signs of deterioration are observed. Adhering to these practices supports the overall reliability and performance of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions, and related technologies. With a strong reputation in the commercial truck industry, Cummins products are known for their quality, durability, and performance. The company’s commitment to innovation and customer satisfaction has established it as a trusted name in the field of diesel engines and related components.

Threaded Plug 3423281 Compatibility with Cummins Engines

The threaded plug part number 3423281, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. Below is a detailed description of its compatibility across different engine models:

QSV81G and QSV91G

The threaded plug 3423281 is specifically engineered to fit the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, making the threaded plug an essential component for maintaining their operational integrity.

QSV91-G4 CM558/CM700 V102

For the QSV91-G4 CM558/CM700 V102 engines, the threaded plug 3423281 is a critical part that ensures proper sealing and functionality. This engine variant is often used in heavy-duty applications, and the threaded plug’s precision fit is crucial for its performance.

QSW/QSV82 and QSW27

The threaded plug 3423281 is also compatible with the QSW/QSV82 and QSW27 engines. These engines are designed for versatility and efficiency, and the threaded plug plays a vital role in their maintenance and operation.

QSW36 and QSW73

Lastly, the threaded plug 3423281 is suitable for the QSW36 and QSW73 engines. These engines are known for their durability and are often used in demanding environments. The threaded plug’s design ensures it fits perfectly, providing the necessary sealing and support.

Each of these engines benefits from the threaded plug’s precision engineering, ensuring optimal performance and longevity.

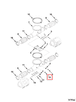

Role of Part 3423281 Threaded Plug in Engine Systems

The part 3423281 Threaded Plug is an essential component in various engine systems, serving multiple functions that contribute to the overall efficiency and performance of the engine.

In the Connection Assembly Exhaust and Exhaust Assembly, the threaded plug is utilized to seal off unused ports or passages, ensuring that exhaust gases flow correctly through the designated pathways. This helps maintain the integrity of the exhaust system and prevents any unwanted leaks that could affect engine performance.

Within the Exhaust Assembly Manifold and Exhaust Manifold, the threaded plug plays a similar role by sealing off any non-operational ports. This is particularly important in manifolds where multiple cylinders exhaust into a single passage; proper sealing ensures uniform exhaust flow and reduces the risk of backpressure issues.

For the Exhaust Manifold Manifold configurations, where manifolds are connected in series or parallel, the threaded plug is used to close off sections that are not in use. This allows for flexibility in engine design and tuning, enabling engineers to optimize exhaust flow for specific performance requirements.

In the broader Manifold systems, whether intake or exhaust, the threaded plug is often employed to block off ports that are not required for a particular engine configuration. This can be especially useful in modular engine designs where different versions of the engine may require different port configurations.

The Multiduct Assembly Connection and Multiduct Connection systems benefit from the threaded plug by allowing engineers to seal off ducts that are not part of the current engine setup. This ensures that air or exhaust flows only through the intended pathways, enhancing system efficiency.

In Turbocharger L6 Assembly and Turbocharger L8 Assembly systems, the threaded plug is used to seal off bypass or relief ports within the turbocharger housing. This helps maintain the desired boost pressure and ensures that the turbocharger operates within its designed parameters.

Lastly, in the Wastegate Assembly Valve, the threaded plug can be used to seal off the wastegate actuator when the wastegate is not in use. This prevents any unintended actuation and ensures that the turbocharger maintains consistent boost levels.

Overall, the part 3423281 Threaded Plug is a versatile component that enhances the functionality and reliability of various engine systems by providing precise sealing solutions.

Conclusion

The Cummins 3423281 Threaded Plug is a vital component in commercial trucks, ensuring the integrity and efficiency of various systems. Its precise design, durable construction, and compatibility with a range of Cummins engines make it an essential part for maintaining operational standards. Proper installation, regular maintenance, and prompt troubleshooting of common issues are crucial for maximizing the performance and longevity of this part.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.