This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Threaded Plug 3686181 is a specialized component designed for use in commercial trucks. Its primary role is to provide a secure seal in various parts of the truck’s system, ensuring the integrity of fluids and preventing leaks. This part is integral to maintaining the operational efficiency and safety of commercial vehicles, particularly in demanding environments where reliability is paramount 4.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in automotive systems. They consist of a threaded body that screws into a corresponding threaded hole, creating a tight seal. These plugs are commonly employed in engines, transmissions, and other fluid systems to prevent the escape of liquids or gases. Their design allows for easy installation and removal, making them suitable for both permanent and temporary sealing applications 3.

Purpose of Cummins Threaded Plug 3686181

The Cummins Threaded Plug 3686181 serves a specific function in the operation of commercial trucks. It is designed to seal openings in the engine block, transmission, or other fluid systems, thereby protecting internal components from contamination and ensuring the proper functioning of the system. By maintaining a secure seal, this plug helps to preserve the integrity of the fluid pathways, which is vital for the overall performance and longevity of the truck 2.

Key Features

The Cummins Threaded Plug 3686181 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a precise thread type that ensures a tight fit, minimizing the risk of leaks. Additionally, its design specifications are tailored to withstand the harsh conditions typical of commercial truck operations, providing reliable performance over an extended period 1.

Benefits of Using Cummins Threaded Plug 3686181

Utilizing the Cummins Threaded Plug 3686181 offers several advantages. Its superior sealing efficiency helps to maintain the integrity of the truck’s fluid systems, reducing the risk of leaks and contamination. The plug’s resistance to corrosion ensures longevity, even in challenging operating environments. Furthermore, its durable construction contributes to the overall reliability and performance of the vehicle, making it a valuable component for commercial truck maintenance 4.

Installation Process

Proper installation of the Cummins Threaded Plug 3686181 is crucial for ensuring optimal performance and safety. The process involves cleaning the threaded hole to remove any debris or old sealant. The plug should then be screwed into the hole by hand until it is snug, followed by tightening it with a wrench to the specified torque setting. Care should be taken to avoid over-tightening, which could damage the threads or the plug itself 2.

Troubleshooting Common Issues

Common issues associated with threaded plugs include leaks and damage. If a leak is detected, the plug should be inspected for proper seating and thread integrity. In some cases, re-torquing the plug may resolve the issue. If damage is found, the plug should be replaced to ensure a secure seal. Regular inspections can help identify potential problems early, allowing for timely maintenance and repairs 3.

Maintenance Tips

To ensure the longevity and reliability of the Cummins Threaded Plug 3686181, regular maintenance practices are recommended. This includes periodic inspections to check for signs of wear, corrosion, or leaks. If any issues are detected, they should be addressed promptly to prevent further damage. Additionally, following the manufacturer’s guidelines for replacement intervals can help maintain the integrity of the truck’s fluid systems 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance products. The company’s commitment to innovation and quality ensures that its components, like the Cummins Threaded Plug 3686181, meet the demanding needs of commercial vehicle operators 4.

Threaded Plug 3686181 Compatibility with Cummins Engines

The Threaded Plug part number 3686181, manufactured by Cummins, is designed to fit a variety of their engine models. This plug is essential for sealing and securing various components within the engine system. Below is a detailed breakdown of the compatibility of this threaded plug with the listed engine models:

ISX12 Series

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

The threaded plug 3686181 is compatible with the ISX12 engines, including both the CM2350 and CM2250 configurations. This plug is used in various sealing applications within these engines to ensure optimal performance and reliability.

ISX15 Series

- ISX15 CM2250

- ISX15 CM2350 X101

For the ISX15 engines, the threaded plug 3686181 fits seamlessly into both the CM2250 and CM2350 configurations. This plug is crucial for maintaining the integrity of the engine’s sealing systems, ensuring that there are no leaks or failures.

QSX11.9 Series

- QSX11.9 CM2250 ECF

The threaded plug 3686181 is also compatible with the QSX11.9 CM2250 ECF engine. This part is used in critical sealing applications to prevent any potential fluid or gas leaks, contributing to the engine’s overall efficiency and longevity.

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The threaded plug 3686181 fits the QSX15 engines across various configurations, including the CM2250, CM2250 ECF, and CM2350 X105. This plug is integral to the engine’s sealing systems, ensuring that all components are securely fastened and sealed.

X12 and X15 Series

- X12 CM2350 X119B

- X15 CM2350 X116B

- X15 CM2450 X134B

The threaded plug 3686181 is also compatible with the X12 and X15 engines. This includes the X12 CM2350 X119B, X15 CM2350 X116B, and X15 CM2450 X134B models. This plug is used in various sealing and fastening applications within these engines, ensuring that all parts are properly secured and sealed.

Role of Part 3686181 Threaded Plug in Engine Systems

In the intricate network of an engine system, the 3686181 Threaded Plug serves as a pivotal component, ensuring the seamless operation of various subsystems. Its primary function is to seal and regulate the flow within specific pathways, contributing to the overall efficiency and performance of the engine.

Air Flow Metering Orifice

The 3686181 Threaded Plug is instrumental in the air flow metering orifice system. By precisely sealing the orifice, it helps maintain consistent air flow measurements. This ensures that the engine receives the correct air-fuel mixture, which is essential for optimal combustion and power output 2.

Exhaust Recirculation Air System

In the exhaust recirculation air (ERA) system, the threaded plug plays a significant role. It seals the ERA passages, preventing unwanted air leaks. This sealing capability is vital for the recirculation process, where a portion of the exhaust gas is reintroduced into the intake stream to reduce nitrogen oxides (NOx) emissions. The plug’s reliable sealing ensures that the recirculation rate remains within specified parameters, enhancing emission control efficiency 3.

Exhaust Gas Recirculation Venturi

Within the exhaust gas recirculation (EGR) venturi, the 3686181 Threaded Plug aids in maintaining the integrity of the venturi shape. By sealing the venturi, it ensures that the pressure differentials necessary for effective EGR are preserved. This contributes to smoother engine operation and reduced emissions by allowing precise control over the recirculated exhaust gas volume 1.

Flow Measurement Venturi

In systems utilizing a flow measurement venturi, the threaded plug is employed to seal the venturi throat. This sealing is essential for accurate flow measurements, as it prevents any bypass airflow that could skew the readings. Accurate flow measurements are fundamental for fine-tuning the engine’s air-fuel ratio, leading to improved fuel efficiency and performance 2.

Plumbing and Recirculation Systems

The 3686181 Threaded Plug is also utilized in various plumbing and recirculation systems throughout the engine. Its role in these systems is to ensure that fluids and gases flow through designated pathways without leakage. This is particularly important in recirculation systems where precise control over fluid dynamics is required to achieve the desired engine performance and emission standards 3.

Exhaust System

Lastly, in the exhaust system, the threaded plug is used to seal off specific points, ensuring that exhaust gases are directed through the intended pathways. This not only aids in emission control but also helps in maintaining the backpressure levels necessary for efficient engine operation 4.

Conclusion

Overall, the 3686181 Threaded Plug is a versatile component that enhances the functionality and reliability of various engine subsystems by providing essential sealing and flow regulation capabilities. Its role in maintaining the integrity of fluid pathways, ensuring accurate measurements, and contributing to emission control makes it a critical component in the operation of commercial trucks.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ ↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ ↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ ↩ ↩ ↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ ↩ ↩ ↩

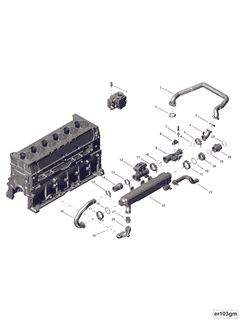

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3348319 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.