3686369

Threaded Pin

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Threaded Pin 3686369, a component manufactured by Cummins, is essential in the commercial truck industry. This part is utilized across various truck models to maintain structural integrity and operational efficiency. Understanding its function and significance is crucial for truck maintenance and operation, ensuring commercial fleets remain reliable and efficient.

Basic Concepts of Threaded Pins

A threaded pin is a fastener with a helical ridge wrapped around a cylindrical body, typically made from materials like steel, stainless steel, or brass for strength, corrosion resistance, and durability 1. In mechanical systems, threaded pins secure components together, providing a stable connection that can withstand significant stress and vibration. They function by being screwed into a corresponding threaded hole, creating a tight fit that holds parts in place.

Role of Threaded Pin 3686369 in Truck Operation

The Threaded Pin 3686369 is integral to the operation of commercial trucks. It is used in various systems and components, including engine mounts, chassis assemblies, and other critical areas where secure fastening is required. By providing a reliable connection, this Cummins part contributes to the overall functionality and reliability of the truck, ensuring that components remain properly aligned and secured under varying operational conditions.

Key Features

The Threaded Pin 3686369 is designed with several key features that enhance its performance and durability. It is crafted from high-quality materials that offer excellent strength and resistance to corrosion. The threading specifications are precise, ensuring a secure fit that minimizes the risk of loosening over time. Additionally, the design of the pin may include features such as a chamfered end for easy installation and a hex head for convenient tightening with standard tools.

Benefits

Using the Threaded Pin 3686369 in truck applications offers several benefits. Its robust construction and precise threading contribute to improved reliability and durability, reducing the likelihood of failure under stress. The ease of installation further enhances its appeal, allowing for quick and efficient maintenance procedures. Additionally, the cost-effectiveness of this part, compared to alternative solutions, makes it a practical choice for fleet maintenance.

Troubleshooting and Maintenance

Common issues associated with the Threaded Pin 3686369 include wear, corrosion, and improper installation. Regular inspection for signs of damage or loosening is recommended to ensure the part remains in optimal condition. Maintenance practices should include cleaning the threaded area before installation to prevent corrosion and using the appropriate torque settings to avoid over-tightening, which can lead to stripping or damage 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company is committed to delivering reliable and efficient components that meet the demanding requirements of modern trucking operations.

Compatibility with Cummins Engines

The Threaded Pin 3686369 is designed to fit a range of Cummins engine models, ensuring secure connections and alignments within the engine components.

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Z14 Series

- Z14 CM2670 Z103B

Each of these engines relies on the Threaded Pin 3686369 for critical assembly and operational functions, underscoring its importance in maintaining the structural and functional integrity of Cummins engines.

Role in Engine Systems

The Threaded Pin 3686369 serves as a pivotal component in the assembly of engine systems, facilitating the secure connection and alignment of various engine components.

Integration with the Engine Block

The engine block relies on the threaded pin to anchor various components securely. By threading into pre-drilled holes within the block, 3686369 ensures that components such as sensors, brackets, or mounting points are held firmly in place, maintaining the structural stability of the engine block.

Cylinder Assembly

Within the cylinder assembly, the threaded pin plays a role in the precise alignment and attachment of cylinder components. It is used to secure cylinder head bolts, ensuring that the cylinder head is properly aligned and sealed against the engine block. This alignment is essential for maintaining compression within the cylinders, directly impacting the engine’s performance and efficiency.

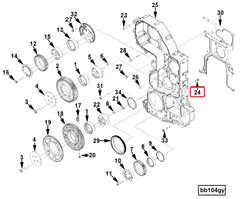

Flywheel Housing

In the flywheel housing, the threaded pin is instrumental in securing the flywheel to the engine. This connection is fundamental for transmitting power from the engine to the transmission system. The secure fit provided by 3686369 ensures that the flywheel operates smoothly, reducing vibrations and enhancing the overall efficiency of power transmission.

Gear Housing

The gear housing, which encases the engine’s gear train, utilizes the threaded pin to secure gears and shafts in place. This securement is crucial for maintaining the precise alignment of gears, which is essential for the smooth operation of the engine’s transmission system. The threaded pin ensures that gears mesh correctly, reducing wear and tear and enhancing the longevity of the gear system.

Conclusion

The Threaded Pin 3686369 is a versatile and critical component that enhances the functionality and reliability of various engine systems. Its role in securing and aligning components within the engine block, cylinder assembly, flywheel housing, and gear housing underscores its importance in the overall performance and durability of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.