This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

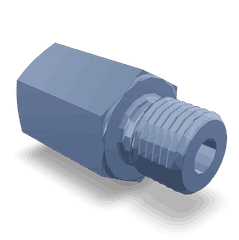

The Threaded Spacer 3696973 is a component produced by Cummins, a prominent entity in the commercial truck industry. This spacer is engineered for use in commercial trucks, where it ensures the proper functioning and longevity of various truck systems.

Purpose and Function

The Threaded Spacer 3696973 is designed to maintain correct spacing and alignment between components within a truck’s engine or transmission system. It is positioned between two mating surfaces to ensure they are held at the correct distance apart. This spacing is essential for the efficient operation of the truck, as it allows for proper clearance and reduces the risk of component interference or misalignment. The spacer provides a stable and consistent gap, which is vital for the smooth operation of mechanical systems 1.

Key Features

This Cummins part is characterized by its precise thread pitch and length, which are tailored to fit specific applications within Cummins engines. It is constructed from high-quality materials that offer durability and resistance to the harsh conditions found in commercial truck environments. The spacer may also feature special coatings or treatments to enhance its corrosion resistance and longevity, ensuring it can withstand the rigors of daily use in demanding applications 2.

Benefits

The use of the Threaded Spacer 3696973 offers several advantages. It improves the alignment of components, which can lead to reduced wear on mating parts. By maintaining the correct spacing, it helps to ensure that mechanical systems operate within their designed parameters, which can enhance overall structural integrity and performance. Additionally, the spacer’s design contributes to the longevity of the truck’s engine or transmission by preventing undue stress on components 3.

Installation Process

Installing the Threaded Spacer 3696973 requires careful attention to detail to ensure proper function. The installation process typically involves cleaning the mating surfaces, applying any necessary lubricants, and then threading the spacer into place. It is important to use the correct tools to avoid damage to the spacer or surrounding components. Additional parts may be required depending on the specific application, and it is advisable to consult the manufacturer’s guidelines for the most accurate installation procedures.

Common Issues and Troubleshooting

Typical problems associated with the Threaded Spacer 3696973 can include wear, corrosion, or improper installation. Wear can occur over time due to the spacer’s exposure to moving parts, while corrosion may result from environmental factors. Improper installation can lead to misalignment or insufficient spacing. To address these issues, regular inspections are recommended, along with the replacement of the spacer if significant wear or corrosion is detected. Ensuring that installation is carried out correctly can prevent many common problems.

Maintenance Recommendations

To ensure the longevity and proper function of the Threaded Spacer 3696973, routine checks should be performed. This includes inspecting the spacer for signs of wear or damage, ensuring that it remains securely in place, and checking for any corrosion. Maintenance practices should also involve keeping the mating surfaces clean and free from debris, which can affect the spacer’s performance. Following these recommendations can help maintain the efficiency and reliability of the truck’s engine or transmission system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all of which are designed to meet the demanding requirements of commercial transportation. Cummins’ commitment to excellence is reflected in its extensive product offerings and its focus on customer satisfaction and support.

Compatibility with Cummins Engines

The threaded spacer part number 3696973, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engines by ensuring proper spacing between components.

ISG12 CM2880 G107

In the ISG12 CM2880 G107 engine, the threaded spacer 3696973 is used to maintain the correct alignment and spacing between critical engine components. This ensures that the engine operates smoothly and efficiently, preventing any misalignment that could lead to performance issues or damage.

QSG12/X12 CM2350 G110

For the QSG12/X12 CM2350 G110 engine, the threaded spacer 3696973 plays a crucial role in maintaining the precise spacing between various parts. This helps in achieving optimal engine performance and longevity by preventing any undue stress on the engine components.

X12 CM2670 X121B

In the X12 CM2670 X121B engine, the threaded spacer 3696973 is integral to the engine’s design. It ensures that all components are correctly spaced, which is vital for the engine’s overall performance and reliability. This part helps in maintaining the engine’s structural integrity and operational efficiency.

By using the threaded spacer 3696973 in these engines, Cummins ensures that the engines maintain their performance standards and operational efficiency. This part is a critical component in the assembly and maintenance of these engines, contributing to their reliability and longevity.

Role of Part 3696973 Threaded Spacer in Engine Systems

In the context of engine systems, the Part 3696973 Threaded Spacer is instrumental in ensuring the proper functioning and alignment of various components.

Turbocharger Systems

When integrated into turbocharger systems, the Threaded Spacer aids in maintaining the correct spacing between the turbocharger and the engine block or manifold. This precise spacing is essential for optimal turbocharger performance, as it ensures that the turbine and compressor wheels operate within their designed parameters. Additionally, the spacer helps in managing thermal expansion, which is a common issue in high-temperature environments typical of turbocharger operations.

Plumbing Systems

In plumbing systems associated with engine cooling or lubrication, the Threaded Spacer plays a significant role in maintaining the integrity of connections. It ensures that hoses, pipes, and fittings are aligned correctly, preventing leaks and ensuring consistent fluid flow. This is particularly important in high-pressure systems where even minor misalignments can lead to significant issues.

General Engine Assembly

Beyond specific systems, the Threaded Spacer is often used in general engine assembly to ensure that components are mounted at the correct distances from each other. This is vital for maintaining the structural integrity of the engine and ensuring that all moving parts operate smoothly without interference. The spacer also aids in vibration damping, which is essential for the longevity and reliability of the engine.

Conclusion

In summary, the Part 3696973 Threaded Spacer is a versatile component that enhances the performance and reliability of various engine systems by ensuring proper alignment, spacing, and structural integrity.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.