This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

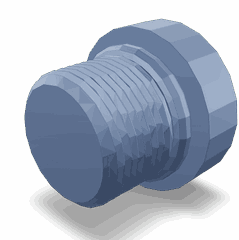

The Cummins 4100941 Threaded Plug is a component designed for specific applications within commercial trucks. Its purpose is to seal openings in various parts of the truck’s engine and systems, ensuring that fluids and gases remain contained within their designated pathways. This part is significant in the context of commercial truck maintenance and operation as it contributes to the integrity and efficiency of the truck’s systems 1.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal threaded holes in various systems. They function by being screwed into place, creating a secure seal that prevents leaks and maintains system pressure. These plugs find applications in a wide range of mechanical systems, including engines, hydraulic systems, and fuel systems, where sealing is crucial for operation and safety 2.

Purpose of the Cummins 4100941 Threaded Plug

The Cummins 4100941 Threaded Plug serves a specific role in the operation of a truck. It is designed to seal openings in the engine or other systems, preventing the escape of fluids or gases. This function is vital for maintaining system pressure and ensuring that the truck operates efficiently and safely 3.

Key Features

The Cummins 4100941 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for its strength and resistance to corrosion, and its thread type, which ensures a secure fit. The design specifications of this plug are tailored to meet the demands of commercial truck applications, providing reliable sealing under various operating conditions.

Benefits

Using the Cummins 4100941 Threaded Plug offers several benefits. It contributes to improved system integrity by ensuring that fluids and gases remain contained within their designated pathways. This, in turn, enhances the performance of the truck’s systems and contributes to the longevity of the vehicle by preventing leaks and maintaining system pressure.

Installation Process

The proper installation of the Cummins 4100941 Threaded Plug involves several steps. It begins with ensuring that the threaded hole is clean and free of debris. The plug is then screwed into place using the appropriate tools to achieve a secure fit without over-tightening, which could damage the threads. Following the manufacturer’s guidelines for torque specifications is important to ensure the plug is installed correctly.

Troubleshooting Common Issues

Common problems with threaded plugs may include leaks due to improper installation or wear over time. Troubleshooting these issues involves inspecting the plug and the threaded hole for damage or misalignment. If a leak is detected, the plug may need to be replaced or the threads repaired to ensure a secure seal.

Maintenance Tips

Regular maintenance of the Cummins 4100941 Threaded Plug is important to ensure optimal performance and longevity. This includes periodic inspection for signs of wear or damage and ensuring that the plug remains securely in place. Following the manufacturer’s recommendations for inspection intervals and care procedures will help maintain the integrity of the plug and the systems it serves.

Role in Engine and System Operation

The Cummins 4100941 Threaded Plug interacts with other components within the truck’s engine and systems by providing a seal for openings that require containment of fluids or gases. Its contribution to overall vehicle performance is significant, as it helps maintain system pressure and efficiency, ensuring that the truck operates smoothly and reliably.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range is designed to meet the demanding requirements of commercial applications, ensuring reliability and performance. The Cummins 4100941 Threaded Plug, as part of this product range, benefits from the company’s expertise and commitment to quality.

Threaded Plug 4100941 in Cummins Engines

The Threaded Plug 4100941, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to ensure proper sealing and functionality in various engine applications.

QSK60 Series

In the QSK60 series, the Threaded Plug 4100941 is utilized in specific configurations to maintain the integrity of the engine’s internal systems. Its role is pivotal in preventing leaks and ensuring that the engine operates efficiently under various conditions.

CM500 Series

Similarly, in the CM500 series, the Threaded Plug 4100941 is integral to the engine’s design. This part is engineered to fit seamlessly into the engine’s architecture, providing a reliable seal that is essential for the engine’s performance and longevity.

Grouping of Engines

The Threaded Plug 4100941 is compatible with both the QSK60 and CM500 series, indicating its versatility and importance across different engine models. Cummins has designed this part to meet the stringent requirements of their high-performance engines, ensuring that it performs consistently across various applications.

Role of Part 4100941 Threaded Plug in Engine Systems

In the context of engine systems, the 4100941 Threaded Plug serves as a vital component in maintaining the integrity and efficiency of various engine components.

Drive System Integration

Within the drive system, the 4100941 Threaded Plug is often utilized to seal openings in the engine block or transmission housing. This sealing function is essential for preventing fluid leaks, which can lead to a loss of lubrication and subsequent damage to moving parts. By ensuring that the drive system remains properly lubricated, the threaded plug contributes to the smooth operation and longevity of the engine.

Fan Assembly Application

In the fan assembly, the 4100941 Threaded Plug plays a role in sealing the housing where the fan blades are mounted. This is particularly important in liquid-cooled engines, where the fan is responsible for dissipating heat from the cooling system. A secure seal provided by the threaded plug ensures that coolant does not escape, maintaining the efficiency of the cooling process and protecting the engine from overheating.

The integration of the 4100941 Threaded Plug in these components underscores its importance in the overall functionality and reliability of engine systems.

Conclusion

The Cummins 4100941 Threaded Plug is a critical component in the maintenance and operation of commercial trucks. Its role in sealing openings within the engine and systems ensures the containment of fluids and gases, contributing to the integrity and efficiency of the truck’s systems. Proper installation, maintenance, and understanding of its role in engine systems are essential for ensuring the longevity and performance of commercial vehicles.

-

Sclar, D. (2008). Auto Repair for Dummies: 2nd Edition. For Dummies.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.