This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4308010 Threaded Plug is a critical component in commercial truck operations, designed to enhance the efficiency and reliability of the vehicle. Understanding its purpose and role is essential for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive and industrial applications. They create a secure, leak-proof seal when screwed into place, commonly utilized in fluid systems to prevent leaks, maintain pressure, and protect internal components from contaminants 1. Their design allows for easy installation and removal, making them versatile for a wide range of applications.

Purpose of the Cummins 4308010 Threaded Plug

The Cummins 4308010 Threaded Plug is designed to seal specific openings within a truck’s engine or other systems. Its function is to ensure that fluids remain contained within their designated pathways, preventing leaks that could lead to system failure or reduced efficiency. By maintaining the integrity of the system, this plug contributes to the overall performance and longevity of the truck 2.

Key Features

The Cummins 4308010 Threaded Plug is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a specific thread type that allows for a secure fit within the designated openings. Its design is tailored to meet the demanding requirements of commercial truck operations, providing reliable sealing under various conditions 3.

Benefits

Utilizing the Cummins 4308010 Threaded Plug offers several advantages. It contributes to improved system integrity by effectively sealing openings and preventing leaks. This results in enhanced performance of the truck’s systems, as fluids are kept within their intended pathways. Additionally, the plug’s durable construction and reliable sealing capabilities contribute to the longevity of the truck, reducing the need for frequent replacements or repairs 4.

Installation Process

Installing the Cummins 4308010 Threaded Plug requires following a series of steps to ensure proper fit and function. Begin by cleaning the area around the opening to remove any debris or contaminants. Use the appropriate tools to screw the plug into place, ensuring it is tightened to the manufacturer’s specifications. It is important to avoid over-tightening, as this can damage the plug or the surrounding components. Once installed, verify the seal by checking for leaks or irregularities.

Common Issues and Troubleshooting

Threaded plugs, including the Cummins 4308010, may encounter issues such as leaks or difficulty in installation or removal. Diagnosing these problems involves inspecting the plug and the surrounding area for signs of damage or wear. Troubleshooting steps may include cleaning the area, ensuring the plug is properly seated, or replacing the plug if it is damaged. Regular maintenance and inspections can help identify and address issues before they lead to system failure.

Maintenance Tips

To prolong the life of the Cummins 4308010 Threaded Plug, regular maintenance practices are recommended. This includes inspecting the plug and surrounding areas for signs of wear, corrosion, or leaks. Cleaning the area around the plug can prevent contaminants from affecting its performance. Following the manufacturer’s guidelines for installation and maintenance ensures the plug continues to function effectively, contributing to the overall reliability of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial operations. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

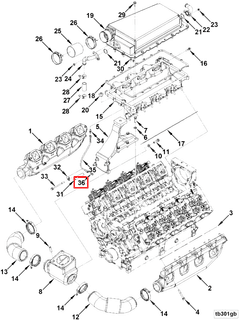

Role of Part 4308010 Threaded Plug in Engine Systems

The Cummins 4308010 Threaded Plug is an essential component in various engine systems, ensuring the integrity and efficiency of these systems. Its applications span across several key components, each playing a distinct role in the overall functionality of the engine.

Turbocharger Systems

In turbocharger systems, the 4308010 Threaded Plug is utilized to seal off unused ports or passages. This ensures that the turbocharger operates within optimal parameters by preventing unwanted air or fluid leaks, which could otherwise degrade performance and efficiency.

Signal Generating Devices

For signal generating devices, the threaded plug is often employed to secure and isolate electrical connections. By doing so, it helps maintain the accuracy and reliability of the signals generated, which are vital for engine management and diagnostics.

Plumbing Systems

Within plumbing systems, the 4308010 Threaded Plug is used to cap off sections of the plumbing that are not in use. This is particularly important in complex engine setups where multiple fluid pathways exist. The plug ensures that fluids are directed correctly through the active pathways, preventing contamination and ensuring system efficiency.

Oil Cooler Systems

In oil cooler systems, the threaded plug plays a role in managing the flow of oil. By sealing off certain passages, it helps regulate the temperature of the oil, ensuring that it remains within the optimal range for engine operation. This is essential for maintaining the longevity and performance of the engine.

Water Systems

For water systems within the engine, the 4308010 Threaded Plug is used to seal off sections of the cooling system that are not in use. This helps in maintaining the correct water flow and pressure, which is crucial for effective engine cooling and overall system stability.

Arrangement and Integration

The integration of the 4308010 Threaded Plug into these systems requires careful arrangement to ensure that it fits securely and performs its intended function without interfering with other components. Proper installation and maintenance of the plug are essential to uphold the efficiency and reliability of the engine systems it supports.

Conclusion

The Cummins 4308010 Threaded Plug is a vital component for maintaining the efficiency and reliability of commercial truck engines. Its role in sealing various systems ensures that fluids remain contained within their designated pathways, preventing leaks and maintaining system integrity. Regular maintenance and proper installation are crucial to prolong the life of this part and ensure optimal engine performance.

-

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.